Directional and universal wheel interchanging device of automatic guided vehicle

An unmanned truck, universal wheel technology, applied in two-dimensional position/channel control and other directions, can solve the problems of high power consumption, loud noise, complex processing technology, etc., to achieve low occupied space height, reduce manufacturing The effect of high cost and control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

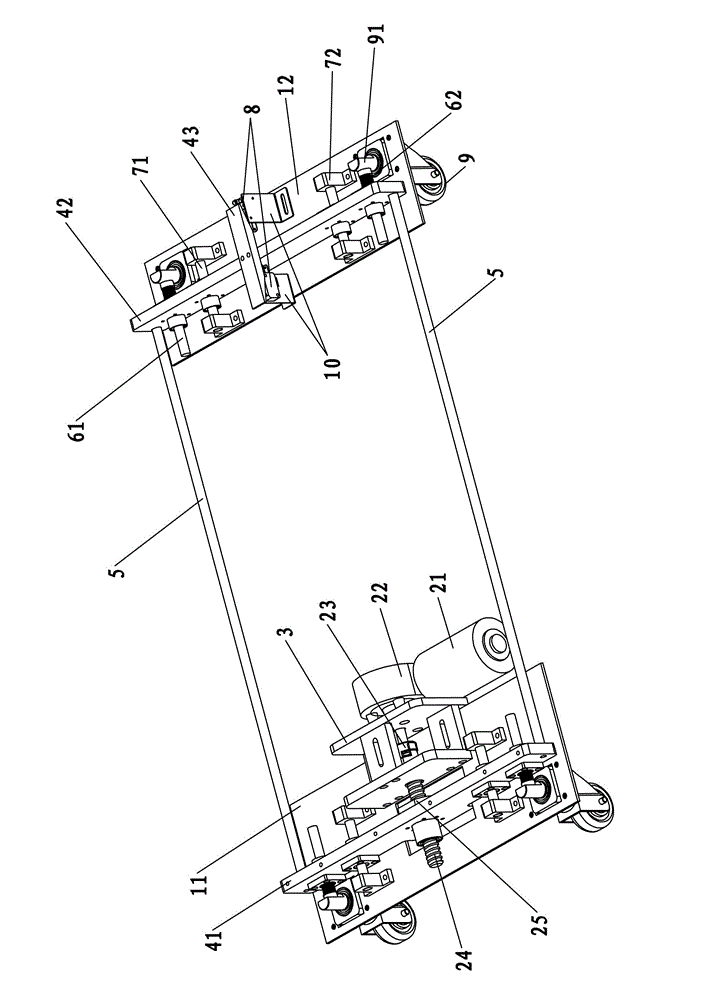

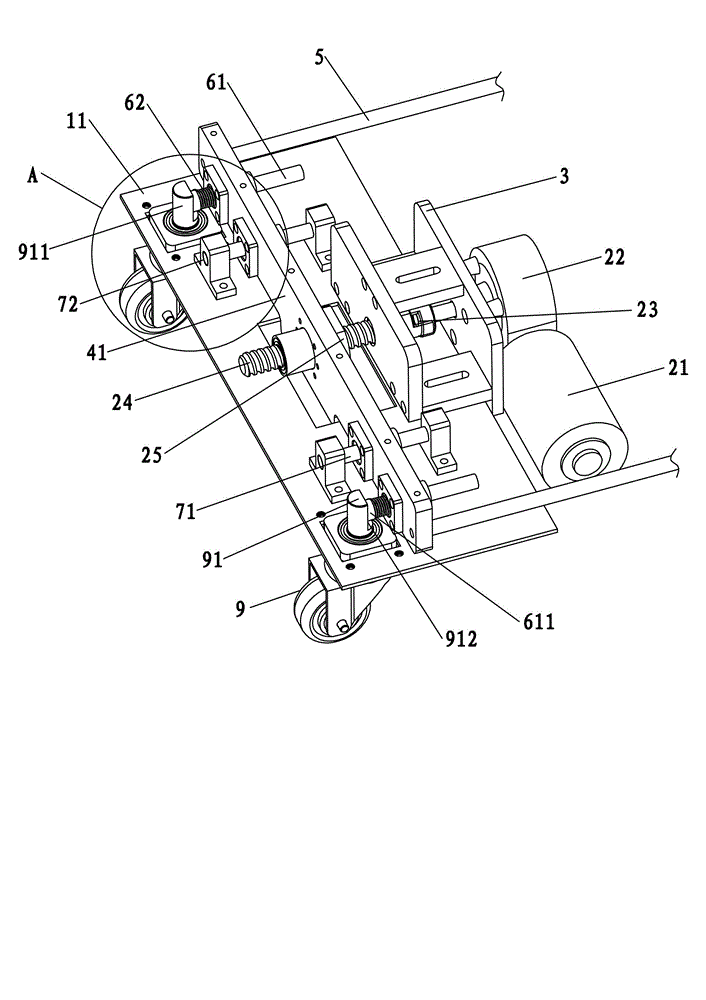

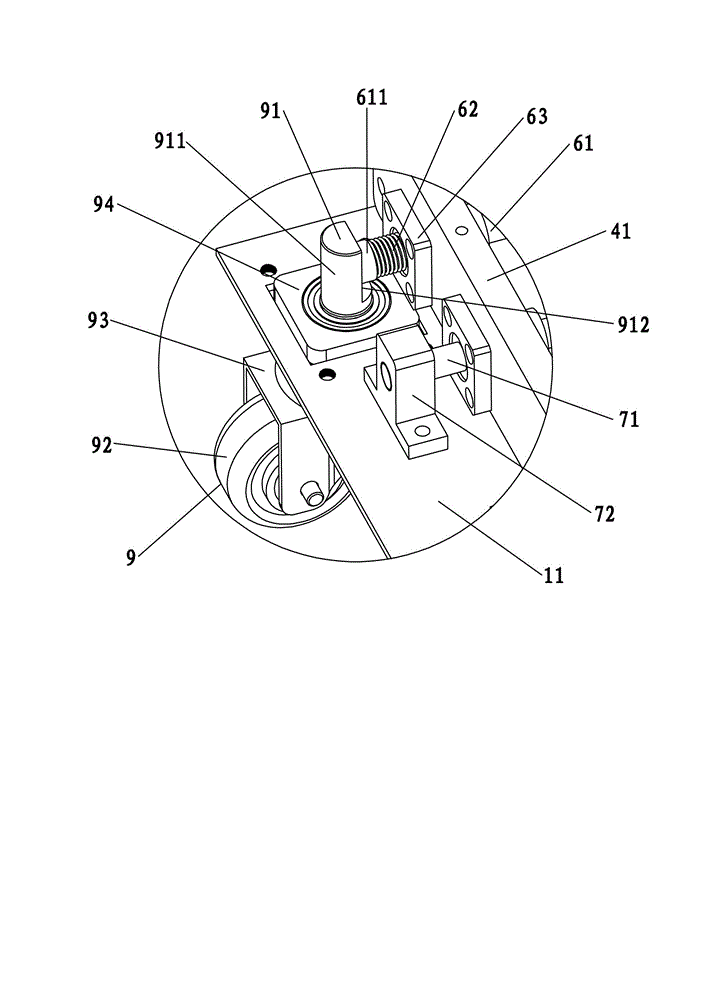

[0026] Such as Figure 1 to Figure 5 As shown, the orientation and universal wheel interchanging device of this unmanned guided vehicle includes universal wheels 9 installed at the front and rear ends of the bottom of the unmanned guided vehicle (AGV) chassis, and the universal shaft 91 of the universal wheel 9 extends Above the chassis, the outer circumference of the cardan shaft 91 includes at least a plane 912 and an arc surface 911. The chassis is also provided with a thimble 61 corresponding to the universal wheel 9. The thimble 61 slides forward and backward on the push plate, and one end points to the cardan. Axis 91 outer periphery, push plate front and back sliding is arranged on the chassis, and is connected with the motor shaft of drive motor 21 by screw rod transmission pair, and drive motor 21 is fixedly arranged on the chassis, and push pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com