High voltage terminal

A terminal, high-voltage technology, applied in electrical components, circuits, semiconductor devices, etc., to reduce costs, shorten processing cycles, and shorten the width of terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in detail below by means of preferred embodiments with reference to the accompanying drawings.

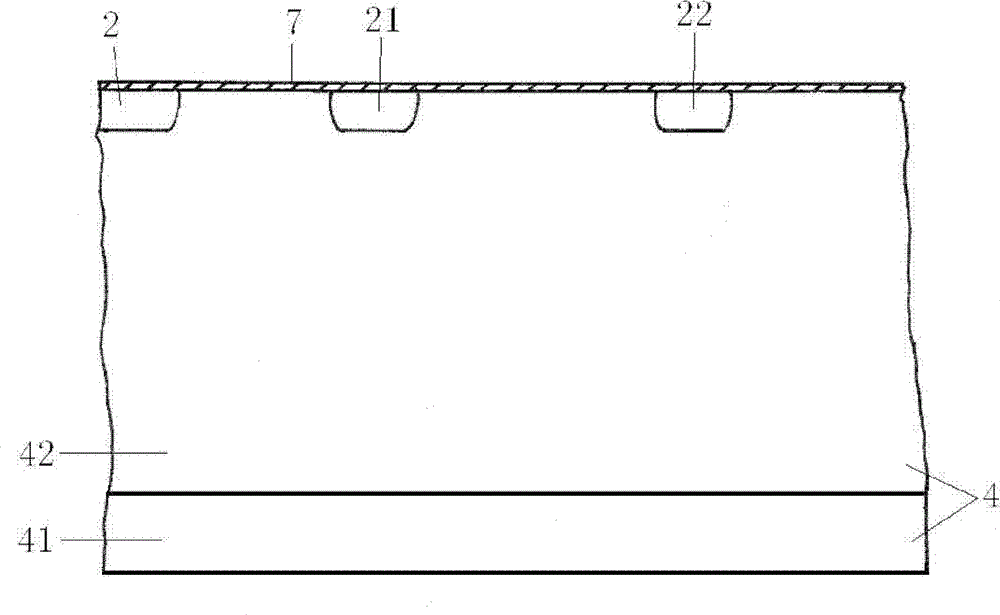

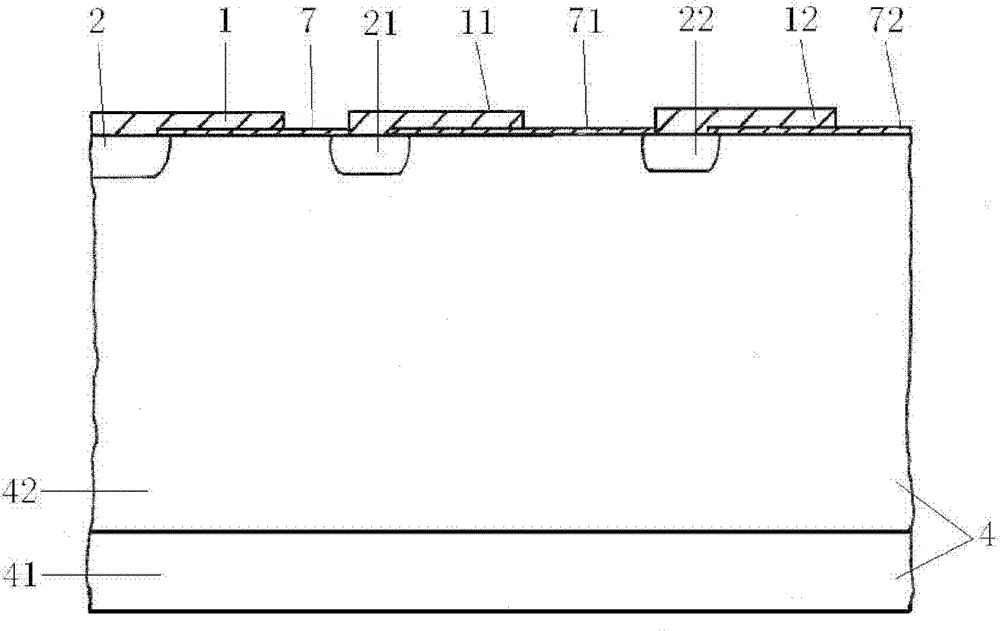

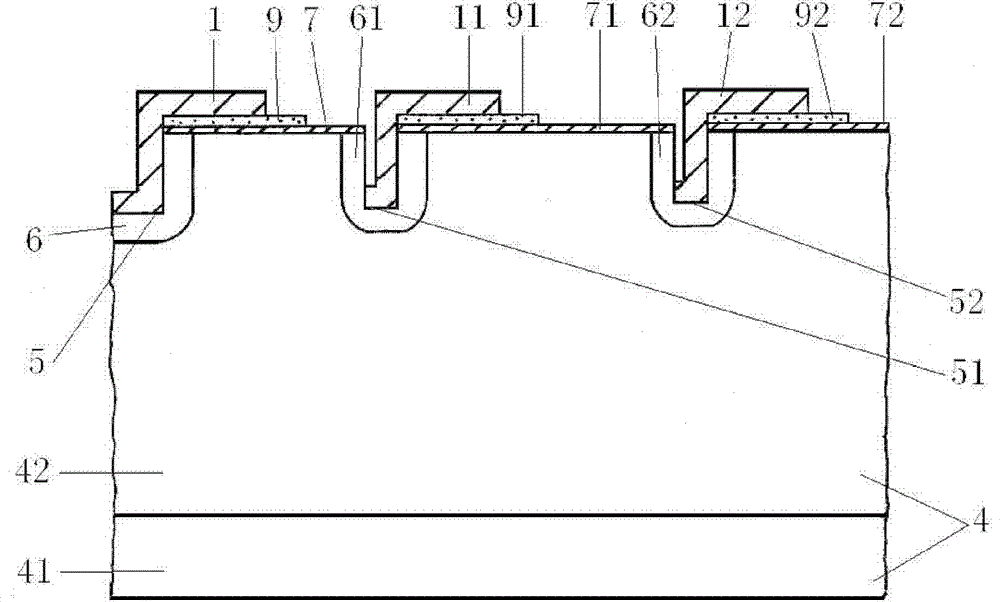

[0016] Among the figure: 1. the aluminum field plate that is connected with the grooved grid region (the prior art is the main junction of the base area): 11. the aluminum field plate that is connected with the first field limiting ring: 12. the second field plate Aluminum field plates connected by rings: 2. P-type base main junction: 21. The first P-type field limiting ring of the prior art high-voltage terminal: 21. The second P-type of the prior art high-voltage terminal Field limiting ring: 4. Silicon substrate: 41. Lower layer of N+ type silicon substrate: 42. Upper layer of N-type silicon substrate: 5. Silicon groove of P+ type groove gate area: 51. The first P+ type groove shape Silicon groove of the field limiting ring: 52. Silicon groove of the second P+ type grooved field limiting ring: 6. P+ type grooved gate area: 61. The first P+ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com