Large-power multilevel converter based on high-frequency isolation transformer

A multi-level converter and isolation converter technology, applied in the field of current conversion, can solve the problems of difficult DC side capacitor voltage balance, complex structure, complex control, etc., to achieve modular design, voltage stress reduction small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

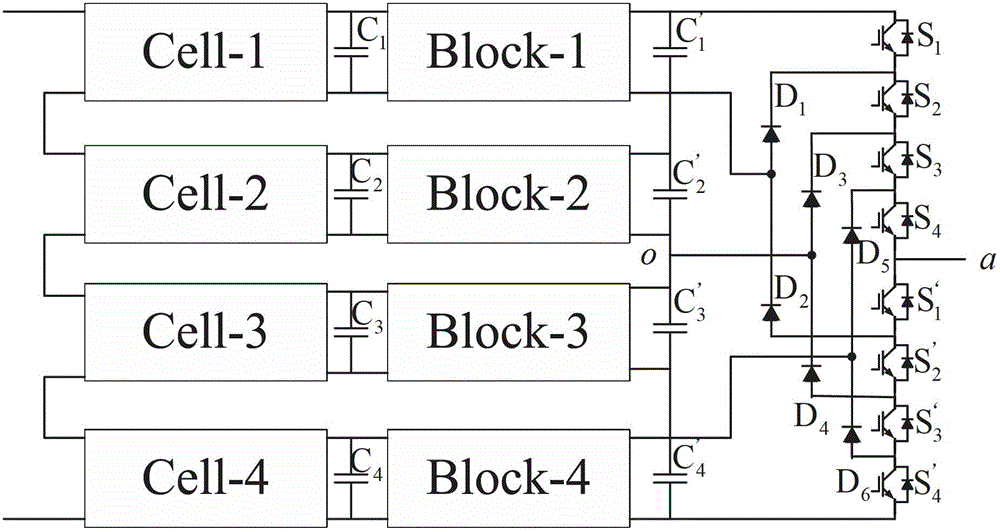

[0035] The single-phase topology of the high-power multilevel converter based on high-frequency isolation conversion consists of an input stage, an intermediate stage and an output stage to form a single-phase five-level topology.

[0036] Among them, refer to figure 1 with figure 2, the input stage is a single-phase cascaded H-bridge rectifier, and the single-phase cascaded H-bridge rectifier includes 4 H-bridge rectifier circuits Cell-n connected in series, where n=1,2,3,4, each H-bridge The rectification circuit Cell includes 4 IGBT modules with anti-parallel diodes, the midpoint of the first bridge arm of the first H-bridge rectification circuit Cell-1 and the second bridge arm midpoint of the fourth H-bridge rectification circuit Cell-4 The single-phase AC input voltage is connected between them, the midpoint of the second bridge arm of the remaining H-bridge rectifier circuit Cell is connected to the midpoint of the first bridge arm of the next H-bridge rectifier circu...

Embodiment 2

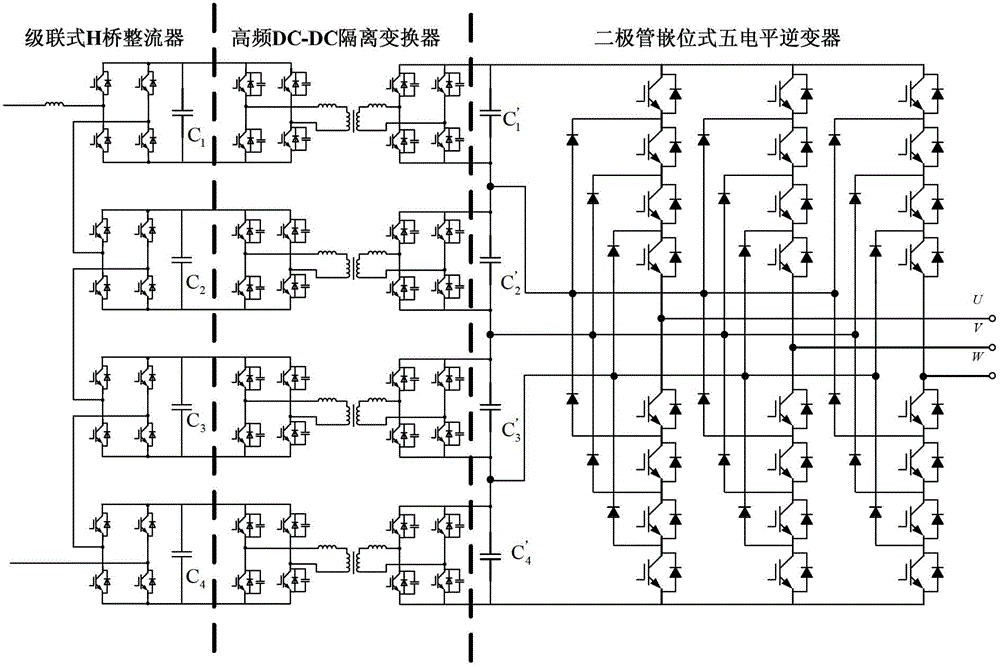

[0040] The three-phase topology of the high-power multilevel converter based on high-frequency isolation conversion consists of an input stage, an intermediate stage and an output stage to form a three-phase five-level topology.

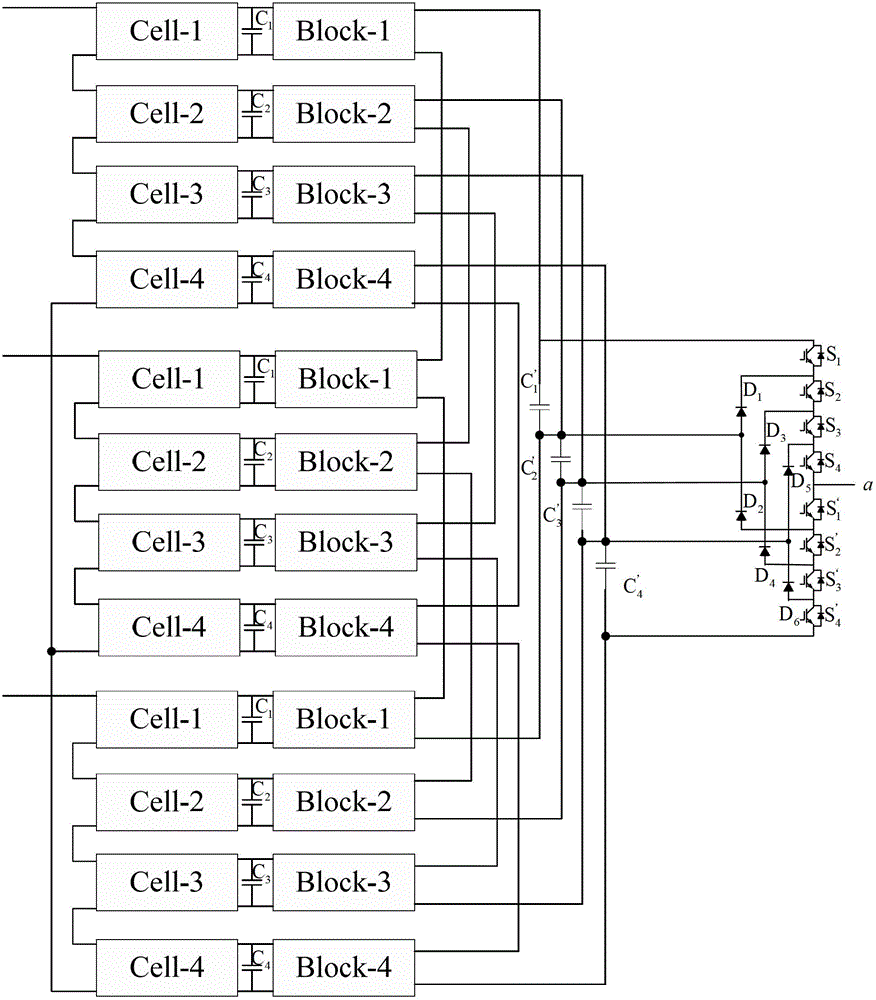

[0041] Among them, refer to image 3 with Figure 4 , the input stage is a three-phase cascaded H-bridge rectifier, the three-phase cascaded H-bridge rectifier includes 3 single-phase cascaded H-bridge rectifiers, and each phase has 4 H-bridge rectifier circuits Cell-n, where n=1, 2, 3, 4, a total of 12 H-bridge rectifier circuits. In each phase, the midpoint of the first bridge arm of the first H-bridge rectifier circuit Cell-1 is used as the three-phase voltage input terminal, and the midpoint of the second bridge arm of the fourth H-bridge rectifier circuit Cell-4 is connected to each other .

[0042] The intermediate stage is a three-phase high-frequency DC-DC isolation converter. The three-phase high-frequency DC-DC isolation converter includ...

Embodiment 3

[0045] The application of the high-power multi-level converter based on high-frequency isolation conversion of the present invention in the converter technology will be described below with Embodiment 3.

[0046] refer to Figure 5 , in the prior art multilevel converter topology using power frequency transformers, the middle points of the first bridge arms of the three H-bridge rectifier circuits are connected to a common point, and the outputs of the three-phase inverters are connected to the three phase motor. On a single bridge arm of each H-bridge rectifier circuit, the conduction state of each switch tube can be divided into -1, 0, 1. The second and third switch tubes T2 and T3 of the H-bridge rectifier circuit are in the 0 state, the first and second switch tubes T1 and T2 of the H-bridge rectifier circuit are in the 1 state, and the third and fourth switches of the H-bridge rectifier circuit are in the 0 state. The conduction of tubes T3 and T4 is in the -1 state. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com