Method for controlling winding current waveforms of switched reluctance motor

A technology of switched reluctance and winding current, which is applied in the direction of AC motor control, electronic commutation motor control, current controller, etc., can solve the problems of large electromagnetic noise, increased current variation range, and unsmooth waveform, and achieve electromagnetic noise Small, smooth current waveform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

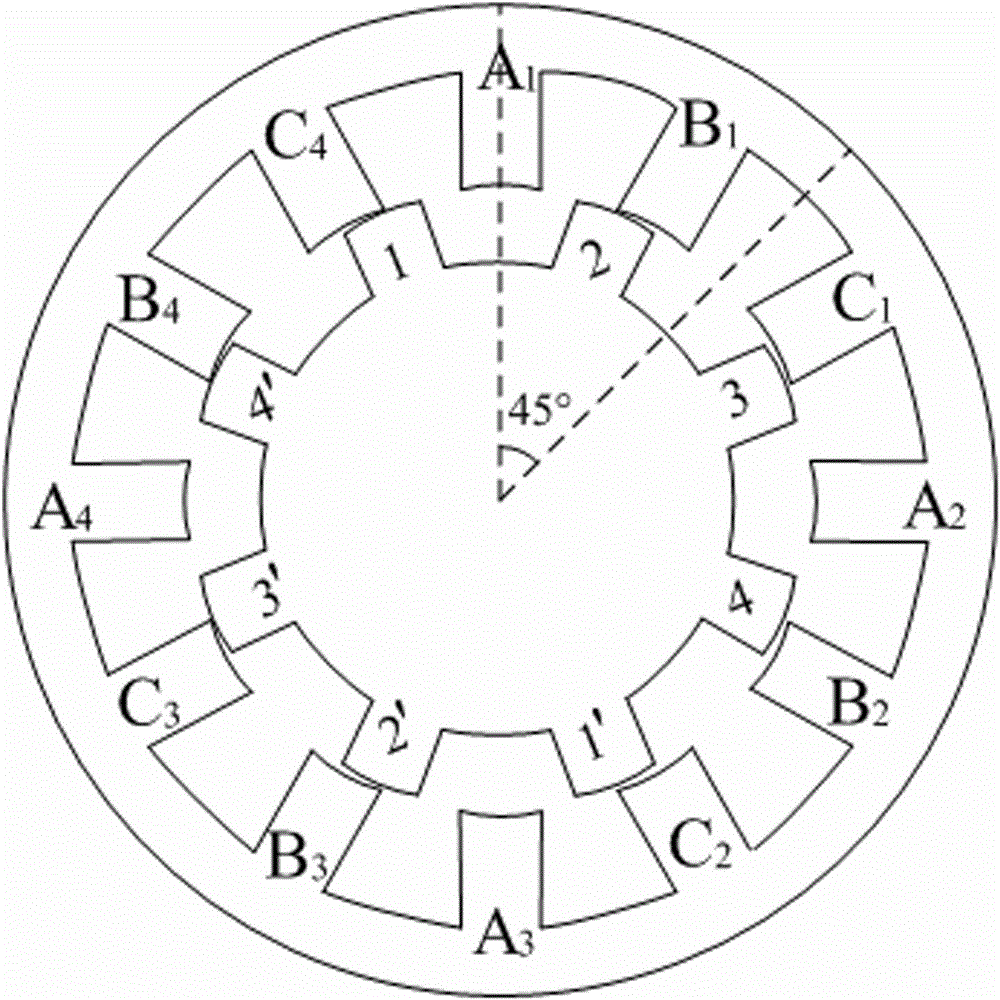

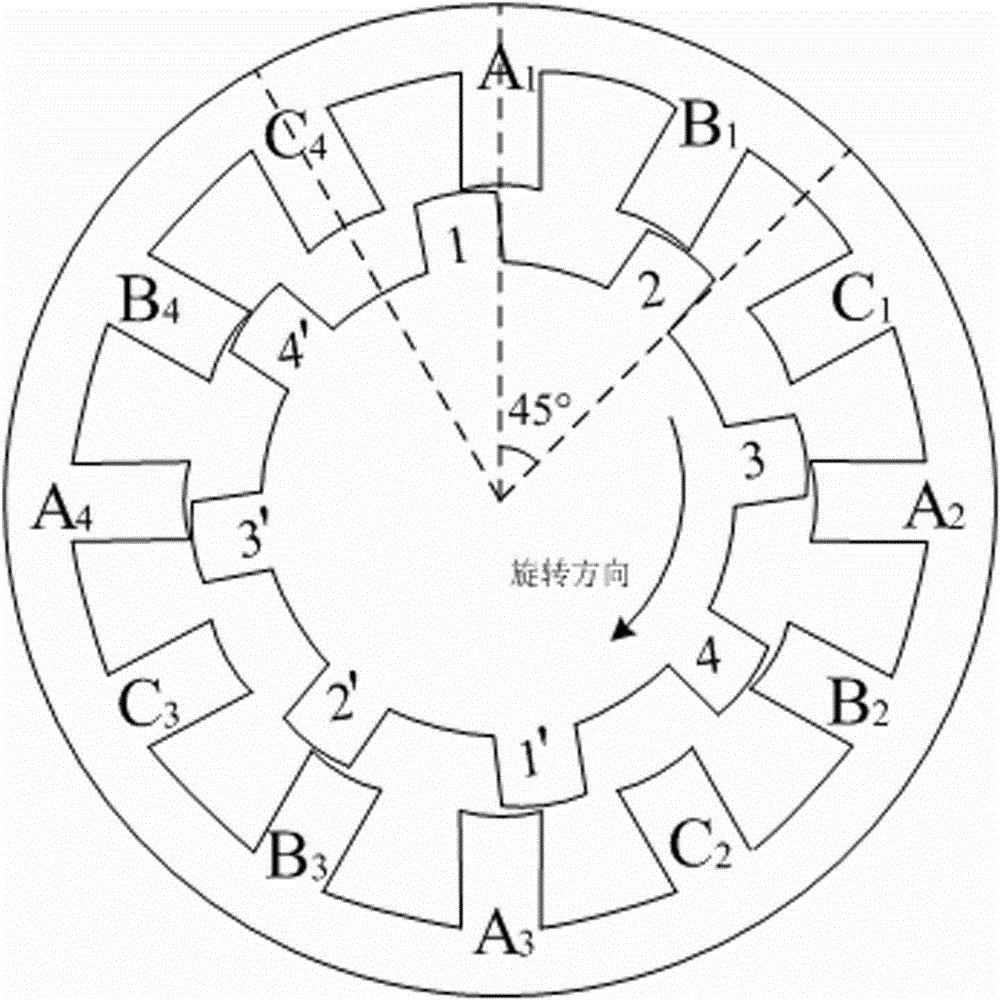

[0014] Taking a three-phase switched reluctance motor with 12 / 8 poles as an example, the embodiment of the present invention is described in detail:

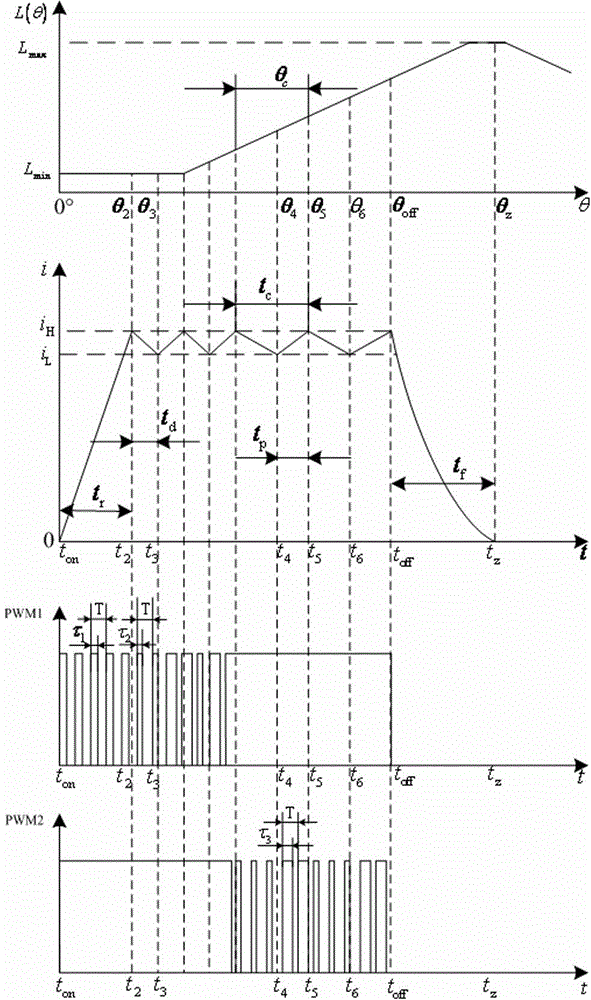

[0015] To implement this control method, the digital signal processor , the switch tube of the power conversion circuit adopts a fully controlled power semiconductor device . The three-phase winding of the three-phase switched reluctance motor includes A phase, B phase and C phase. figure 1 There are four curves in total, among them, is the inductance curve of phase A winding, i is the corresponding phase A winding current waveform, and are the upper switching tube and the lower switching tube connected in series with the A-phase winding respectively Drive signal curve. like figure 1 As shown, the phase A winding curve minimum inductance region of the The position, that is, the position where the stator salient pole of the A phase winding is aligned with the center of the rotor groove starts to be energized, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com