Intelligent heating stirrer and method for controlling same

A technology of intelligent heating and intelligent controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

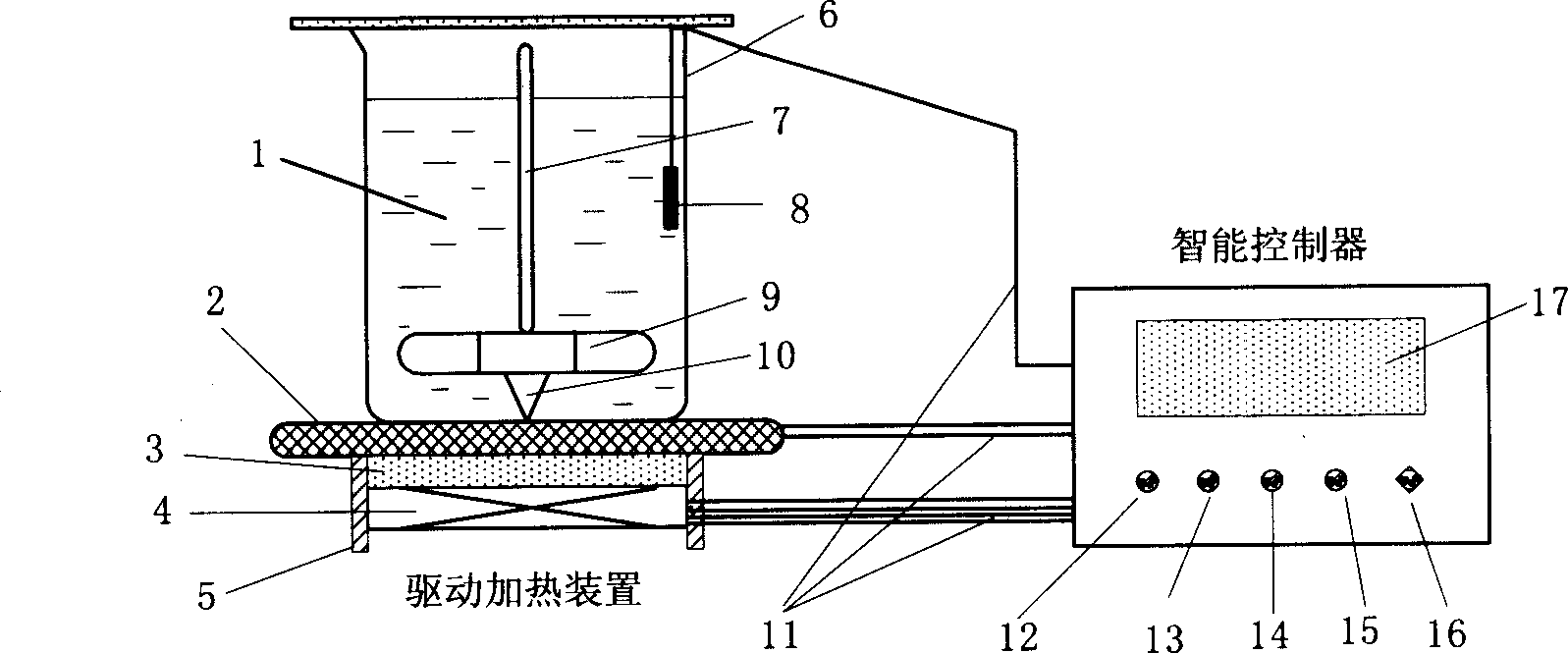

[0039] The intelligent heating agitator and its control method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

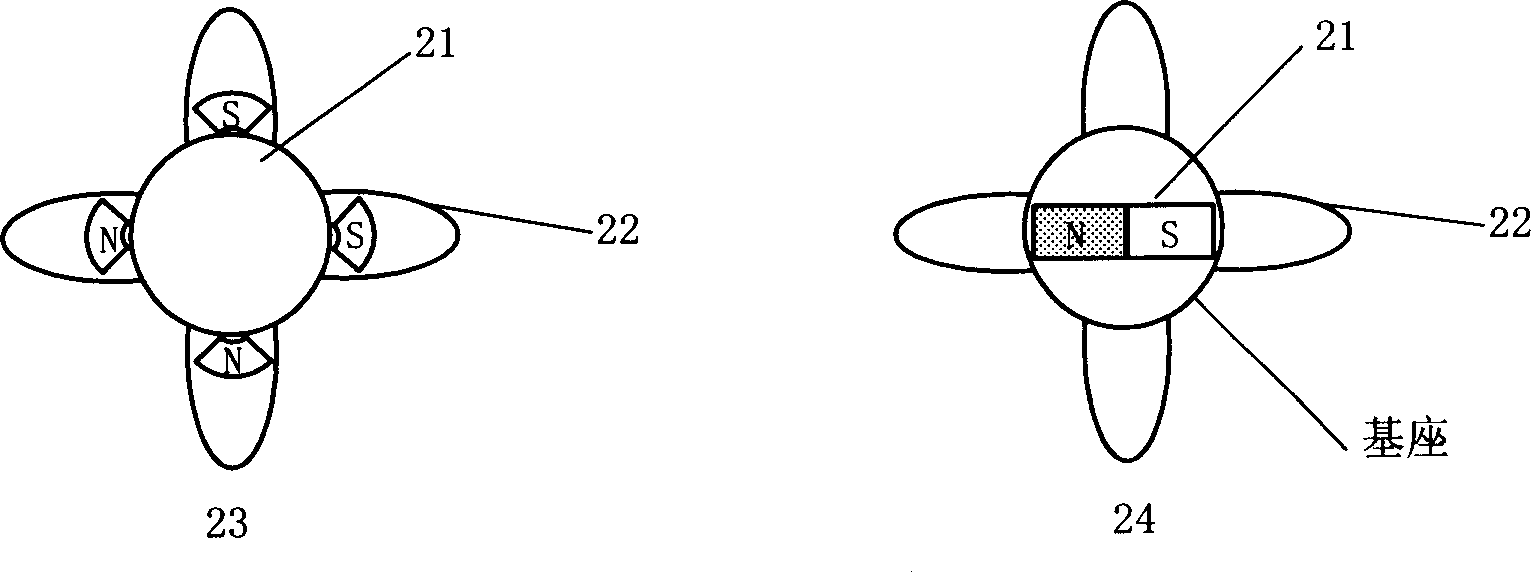

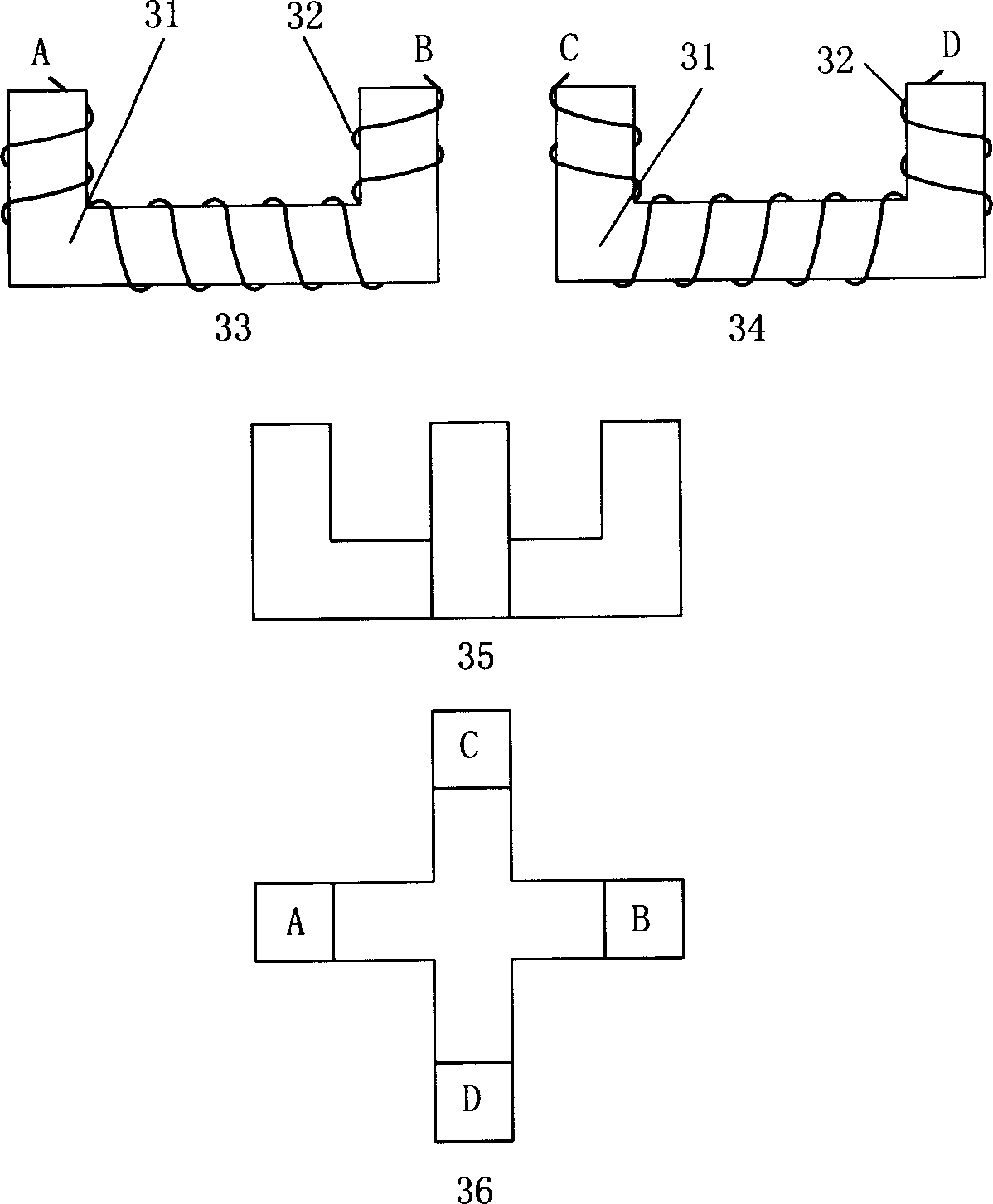

[0040] Such as figure 1 As shown, the intelligent heating stirrer of the present invention comprises a permanent magnetic stirrer, a driving and heating device, an intelligent controller, and a temperature sensor; 4 permanent magnets of the permanent magnetic stirrer are opposite to the electromagnets of the driving device, and when the driving device When the magnetic field generated by the electromagnet rotates, the permanent magnetic stirrer will rotate accordingly; the electromagnet is composed of two U-shaped iron cores inlaid together and wound coils, such as image 3 As shown, the two sets of coils are completely independent.

[0041]The method of generating the rotating magnetic field: 1) when there is no current in the two groups of coils, the electromagnet has no magnetism; 2) when there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com