Equipment and method for detecting temperature coefficient of remanence

A technology of temperature coefficient and detection equipment, which is applied in the direction of magnetic performance measurement, etc., can solve the problems of low precision, small magnetic flux signal, and inability to meet the detection requirements of low temperature coefficient and ultra-low temperature coefficient, so as to reduce electromagnetic noise and improve signal noise than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

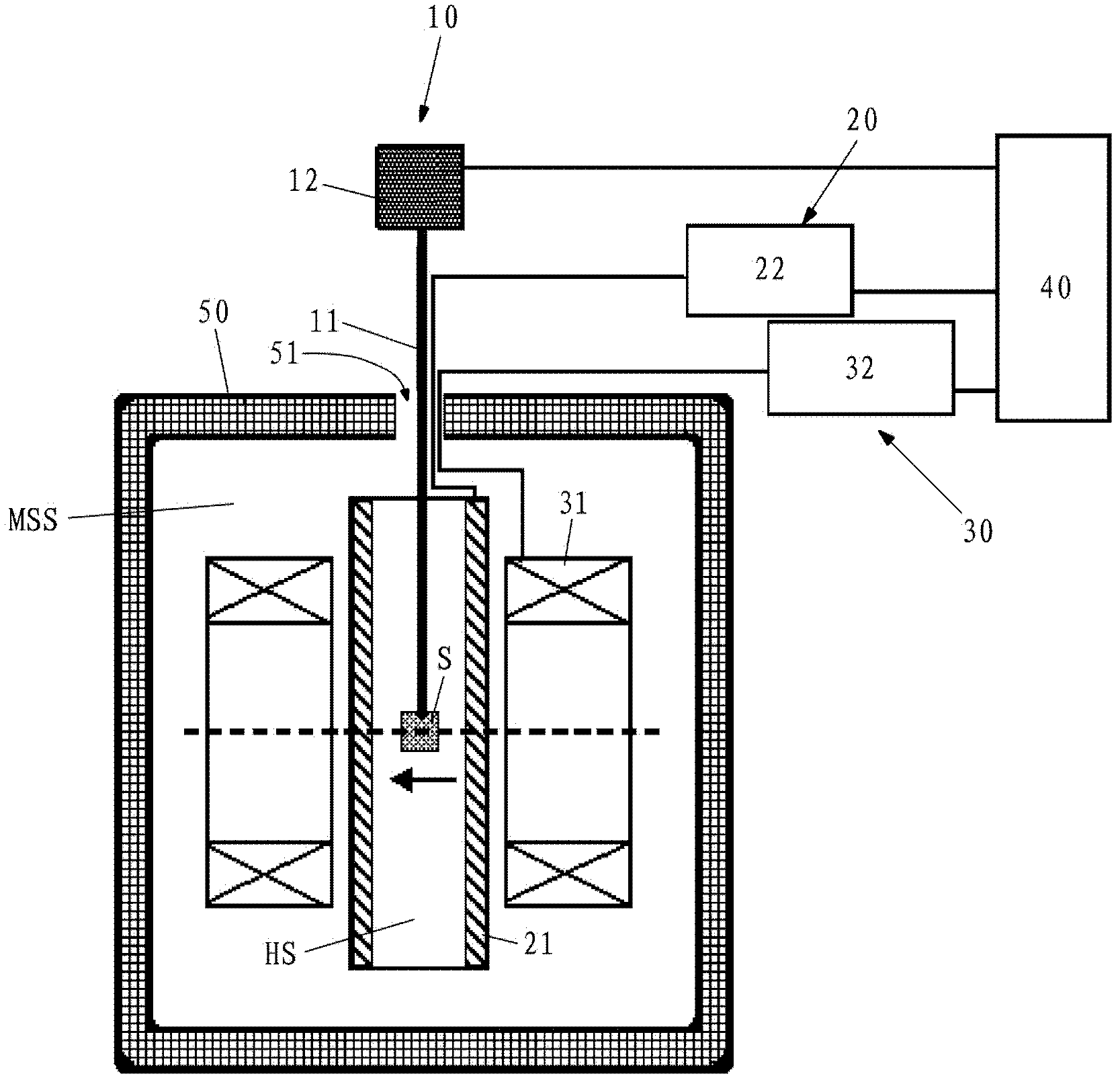

Method used

Image

Examples

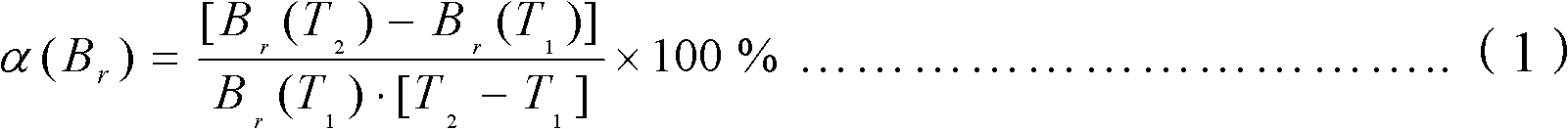

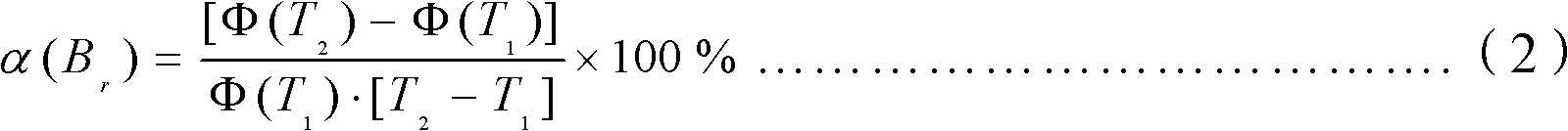

example 1

[0071] The sample S to be tested can be a low temperature coefficient 2:17 type samarium cobalt permanent magnet material. For each temperature point, such as 20 ° C and 100 ° C, the magnetic flux detection is carried out 6 times, and the detection results of each time are listed in Table 1 . It can be seen that each detection result is very close, that is, the drift of the remanence temperature coefficient detection device according to the exemplary embodiment of the present invention is small, and the signal-to-noise ratio is high. The open-circuit reversible remanence temperature coefficient α(B r ) is -2.2×10 -5 / °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com