Multifunctional built-in electric heating thin-film type heating structure

A heating structure and film-type technology, applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of complicated manufacturing of electric heating wire heating devices and low thermal efficiency of electric heating wire heating devices, and achieve shortening of heating time and power Convenient control and accurate temperature detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing (embodiment):

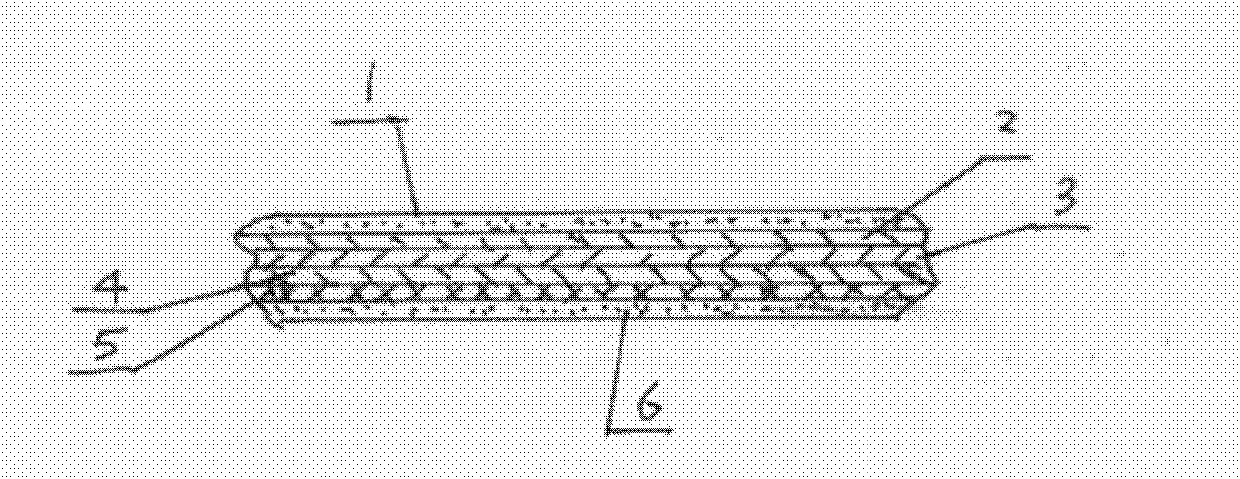

[0016] refer to figure 1 , the present invention comprises electrothermal film 3, upper insulation layer 2, lower insulation layer 4, heat insulation layer 5 and heating body etc.; Heating body is a sandwich structure, is divided into surface layer 1, bottom layer 6; The upper surface of electrothermal film 3 is coated with There is an upper insulating layer 2, and the lower surface is coated with a lower insulating layer 4; the heat insulating layer 5 is coated outside the upper insulating layer 2 or the lower insulating layer 4 (it is also possible to first coat the heat insulating layer 5 on one side of the electric heating film 3, Then coat the insulating layer 2 and the lower insulating layer 4) on both sides of the electrothermal film 3); the electrothermal film 3 coated with the upper insulating layer 2, the lower insulating layer 4 and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com