Heat exchanger for a hot fuel cell

一种热交换器、燃料电池的技术,应用在燃料电池热交换、燃料电池、燃料电池应用等方向,能够解决增加热电联产系统成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

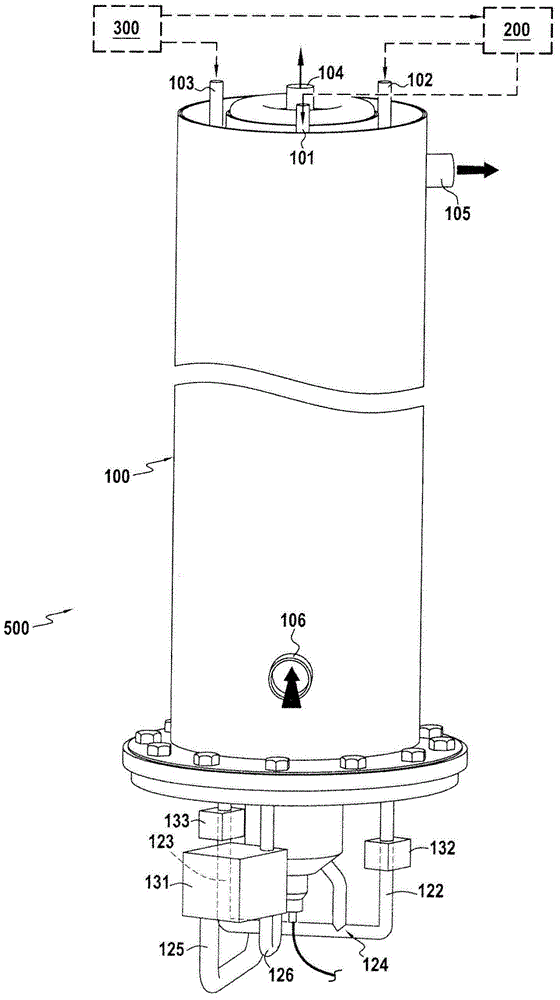

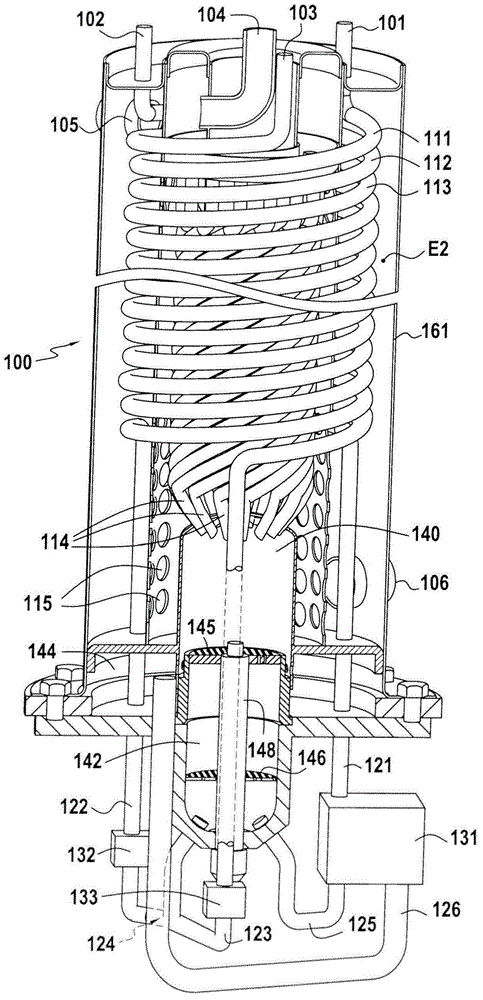

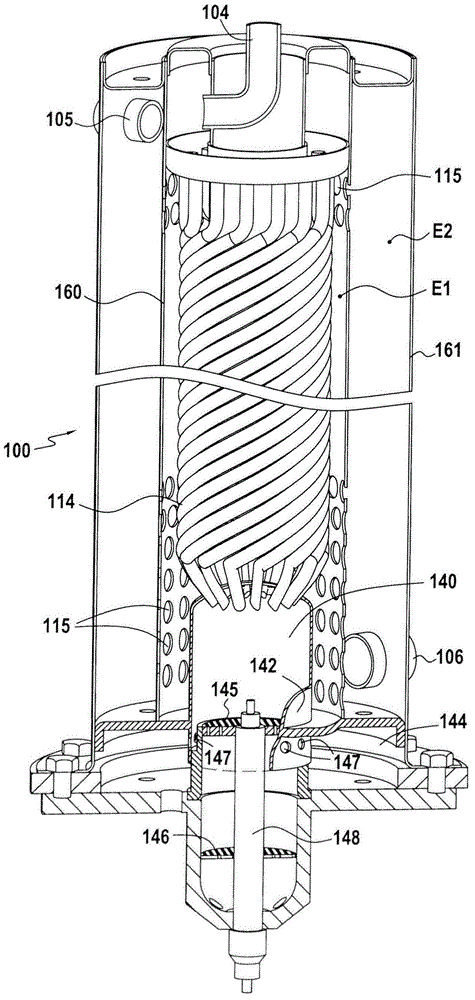

[0040] figure 1 A combined heat and power system 500 according to the invention is shown.

[0041] The combined heat and power system 500 includes:

[0042] The heat exchanger 100 in the first embodiment of the present invention; and

[0043] Thermal fuel cell 200 and reformer 300 downstream of heat exchanger 100 .

[0044] In a known manner, thermal fuel cells operate at very high temperatures, above 650°C. As an example, such a cell is a solid oxide fuel cell, commonly referred to as an SOFC, which operates at a temperature of about 900°C. The structure and operation of fuel cells of that type are known and will not be described in more detail here.

[0045] In order to operate (i.e., to enable the electrochemical redox reaction to proceed simultaneously with electricity generation), the electrodes of the cell need to be supplied separately with a fuel gas (typically hydrogen) and an oxidant gas (i.e., oxygen contained in the air stream supplied to the cell, for example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com