Grain puffing machine and method for preparing puffed grain

An extruder and grain technology, which is applied in food preparation, food science, application, etc., can solve the problems of difficult to guarantee the quality of processed grain, reduce the service life, and low degree of automation, so as to achieve a high degree of automation, ensure quality, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

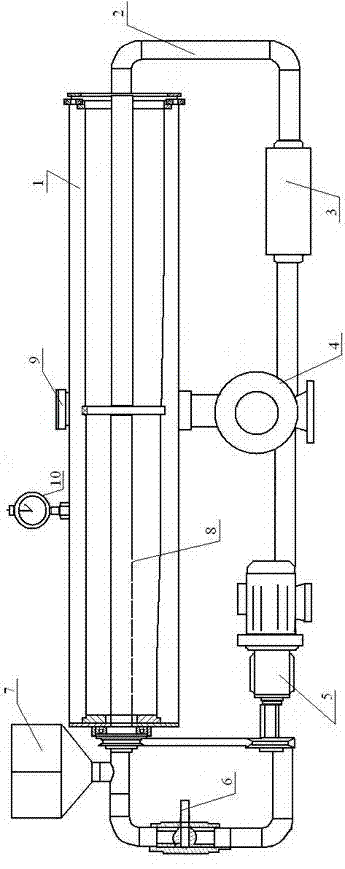

Image

Examples

Embodiment 2

[0026] Adopt equipment of the present invention to prepare the method for puffed glutinous rice, comprise the steps:

[0027] (1) Pass air into the sealed material box 1 and heat it to a temperature of 220°C, and keep the hot air circulation inside;

[0028] (2) Send the glutinous rice into the sealed material box 1 through the feeding funnel 7;

[0029] (3) The sealed material box is rotated to keep the temperature of the hot air inside it stable, and to ensure a stable pressure of 0.015mpa, and the rotation time is 3 hours; the amount of air introduced into the sealed material box is 4000 m per hour 3 .

[0030] The working process of the grain puffing machine is the same as that of embodiment 1.

Embodiment 3

[0032] The method for preparing puffed corn flakes by using the equipment of the present invention comprises the following steps:

[0033] (1) Pass air into the sealed material box 1 and heat it to a temperature of 200°C, and keep the hot air circulation inside;

[0034] (2) Send the corn flakes into the sealed material box 1 through the feeding funnel 7;

[0035] (3) The sealed material box 1 rotates to keep the temperature of the hot air inside it stable, and to ensure a stable pressure of 0.015mpa, and the rotation time is 3 hours; the amount of air introduced into the sealed material box 1 is 4000 m per hour 3 .

[0036] The puffing working process of the grain puffing machine is the same as that of embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap