Integrated ore-dressing machine

A mineral concentrator and magnetic separator technology, applied in the field of mining machinery, can solve the problems of increased production cost of mineral processing, single function and structure, low equipment utilization rate, etc., and achieve the effect of convenient equipment layout, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

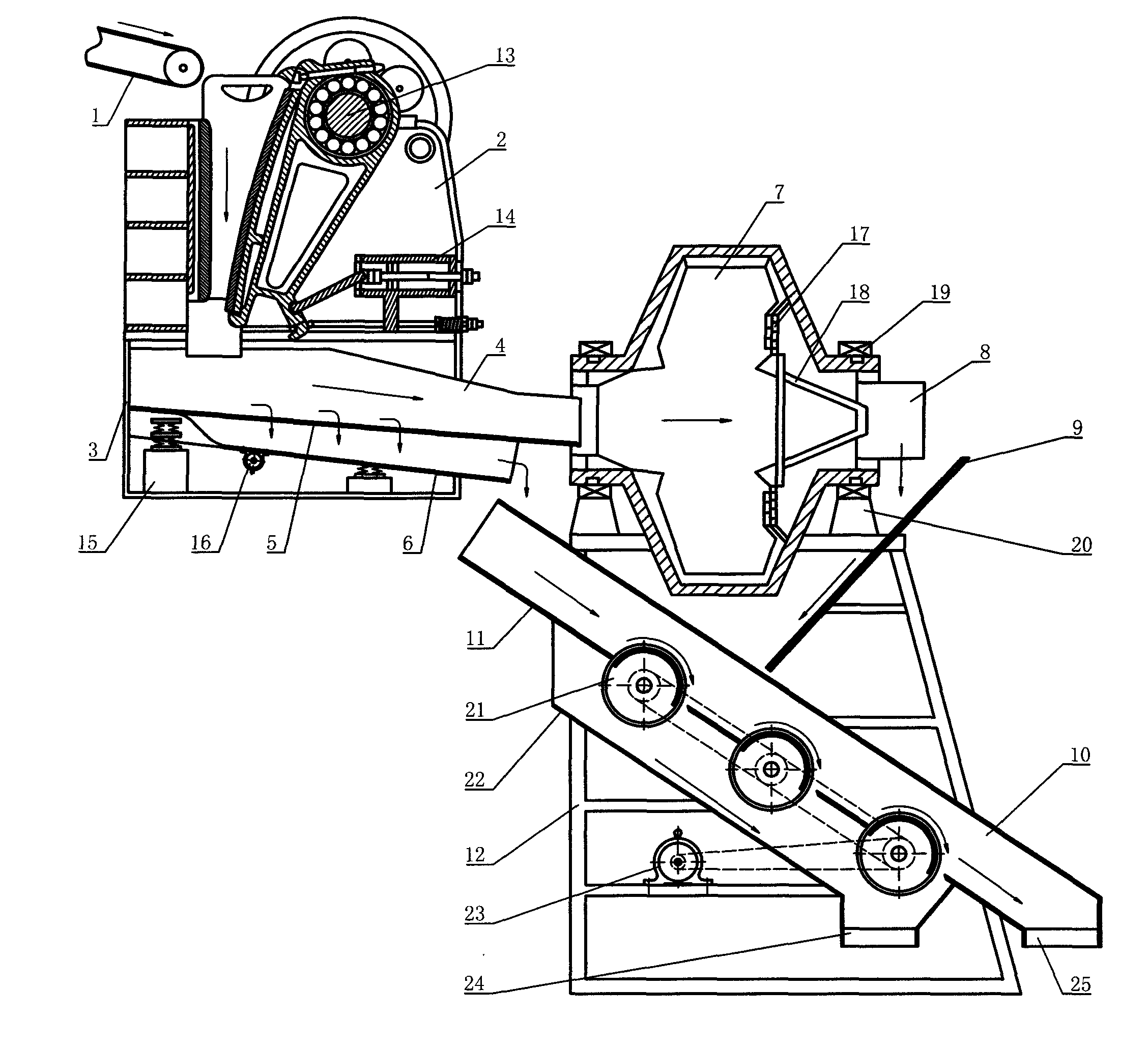

[0014] A kind of integrated ore concentrator of the present invention, as shown in accompanying drawing, is made up of conveyer belt 1, crusher 2, vibrating screen 4, self-grinding machine 7 and magnetic separator 10; Wherein crusher 2 comprises crusher frame 3, The eccentric shaft 13, which is composed of two parts with equal eccentricity and opposite eccentric direction, and a regulator 14 to adjust the size of the discharge port, adopts a double-action jaw crusher; the vibrating screen 4 includes supports and fixes it on the crusher frame 3 The spring support 15 on the upper part is provided with a vibrating motor 16, which is connected to the upper sieve plate 5 of the feeding port of the autogenous mill 7 and the lower sieve plate 6 of the upper feeding plate 11 of the magnetic separator 10; the autogenous mill 7 includes The ore discharge sieve plate 17, the self-returning device 18 and the cylindrical sieve 8 arranged at the discharge end, the bearings 19 that are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com