Bearing bush hydroforming equipment

A technology of hydroforming and bearing bush, applied in the field of bearing bush hydroforming equipment, can solve the problems of difficult fixing of bearing bush and poor processing effect of bearing bush, and achieve the effect of good quality, cost saving, space and stable force application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

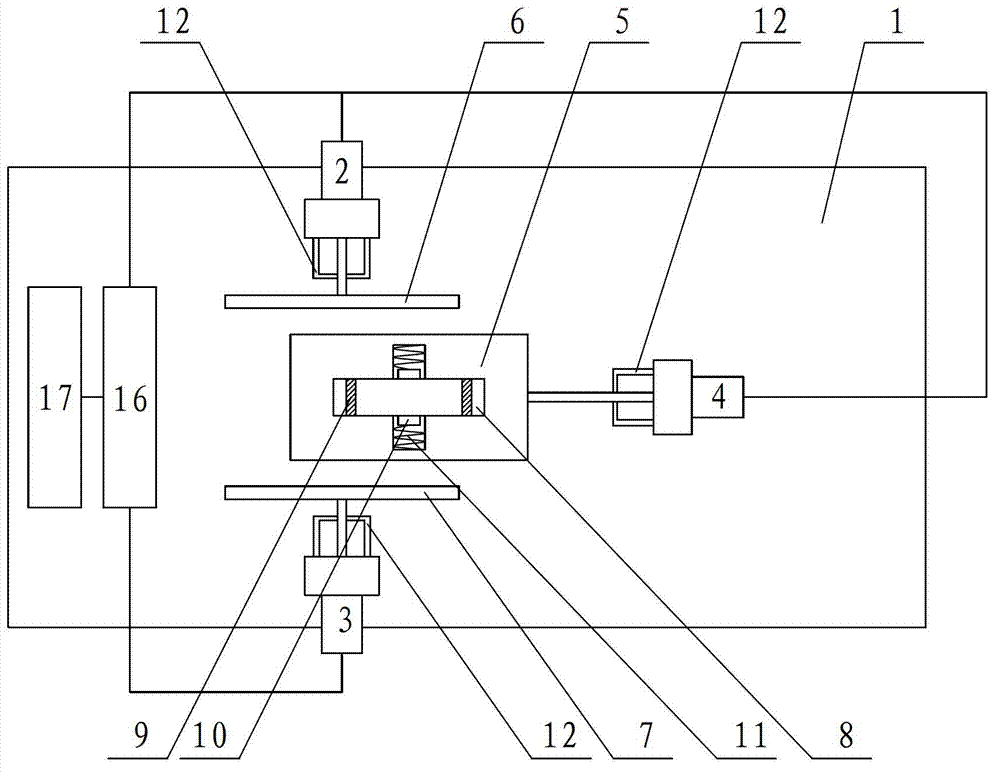

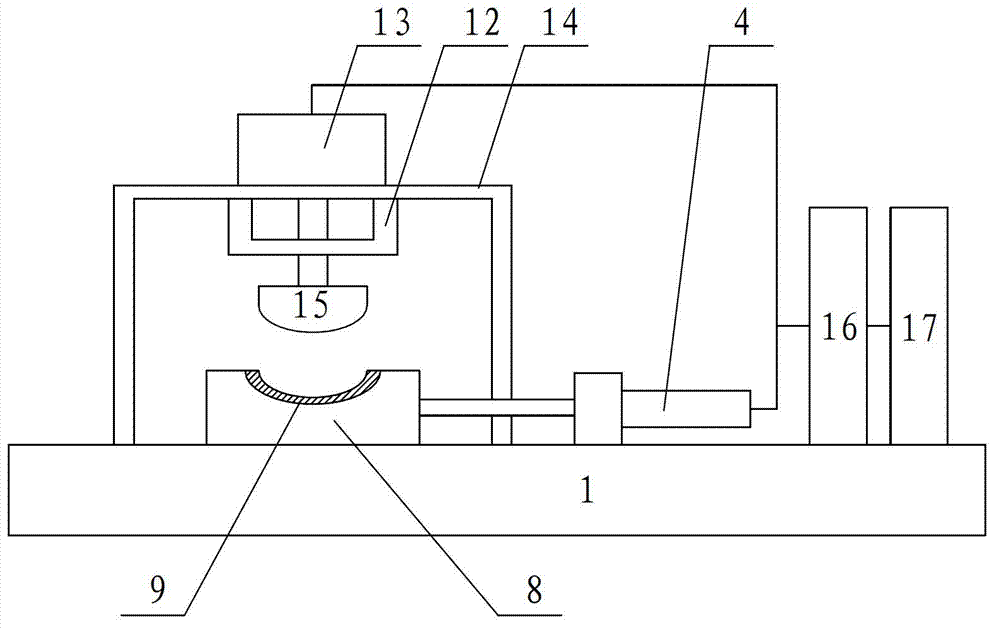

[0014] A bearing pad hydroforming equipment is proposed, including a base 1 on which a first hydraulic mechanism 2, a second hydraulic mechanism 3, a third hydraulic mechanism 4, a fourth hydraulic mechanism 13, a hydraulic cylinder 17, an oil station 16, and a hydraulic cylinder 17 Supply oil to the first hydraulic mechanism 2, the second hydraulic mechanism 3, the third hydraulic mechanism 4, and the fourth hydraulic mechanism 13 respectively through the oil station 16, a movable plate 5 is set on the base 1, and the fourth hydraulic mechanism 13 is fixed by a bracket 14 Above the movable plate 5, the fourth hydraulic mechanism 13 is telescopically connected to the top 15, and the bottom of the top 15 is provided with a protrusion matching the inner surface of the bearing bush 9. The third hydraulic mechanism 4 is telescopically connected to the movable plate 5, and the movable plate 5 is respectively connected by two sets of springs 11. The two sets of stoppers 10 are movabl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap