Chassis system for pure electric explosion-proof vehicle

A chassis, explosion-proof technology, applied in the direction of brakes, brake components, vehicle parts, etc., can solve the problems of non-explosion-proof and low transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

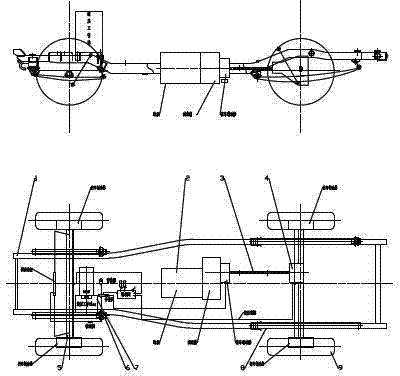

[0006] see figure 1 , The pure electric explosion-proof vehicle chassis system includes: 1. Vehicle frame, 2. Electric powertrain (including explosion-proof drive motor, gearbox and wet parking brake), 3. Drive shaft, 4. Drive axle (with multi-disc wet type Brake), 5. Front axle (with multi-disc wet brake and steering cylinder), 6. Front suspension, 7. Rear suspension, 8. Hydraulic system, 9. Anti-static tires.

[0007] The electric powertrain 2 is integrated by an explosion-proof driving motor, a reduction box and a wet parking brake. Connection, the rigid connection of this shell to the shell makes it form an integral structure. In addition, the drive motor is explosion-proof, and the wet parking brake is a multi-disk safety failure type, which is used for parking and emergency braking of the vehicle on a slope.

[0008] The electric powertrain 2 is placed in the middle, that is, it is arranged between the front and rear axles and installed on the frame 1 through rubber sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com