Opened type airplane hot-gas anti-icing test device

A test device and open technology, applied in the field of open aircraft hot air anti-icing chamber test device, can solve the problems of high processing cost, lack of experimental research work, and great influence of heat transfer, etc., and achieve the effect of reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

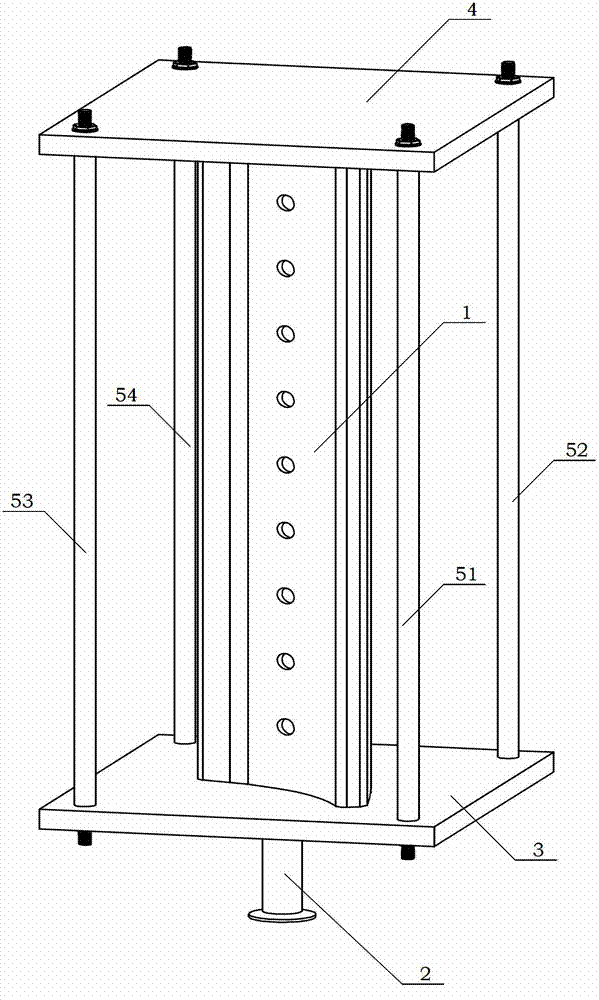

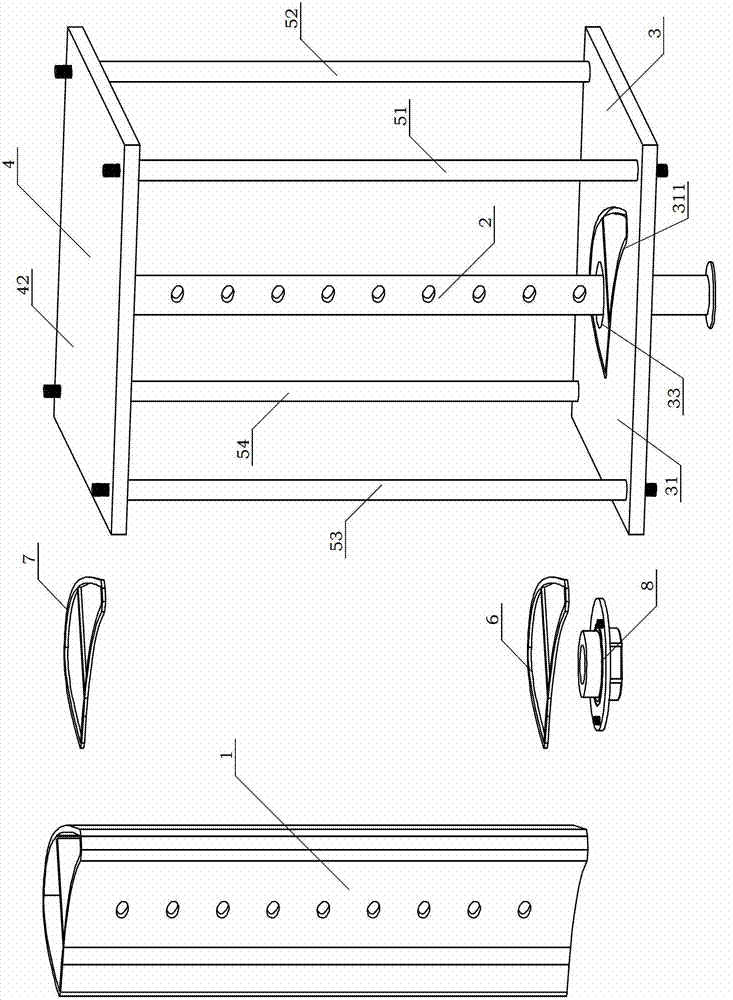

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

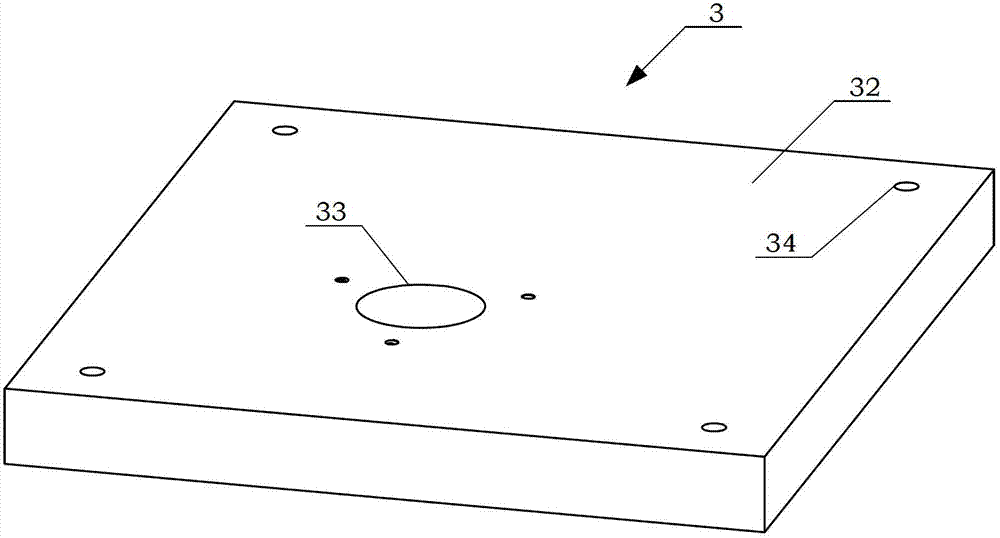

[0041] see Figure 6 , Figure 6AAs shown, the cavity 1 of the aluminum airfoil type hot air anti-icing cavity is divided into the first wing cavity 11 and the second wing cavity 12 through the partition plate 13, and there is a gap between the partition plate 13 and the anti-icing wall surface 17 at the leading edge of the cavity. There is a slit 14, which is used to transfer the hot air entering from the air supply flute 2 to the second wing chamber 12; the airfoil hot air anti-icing chamber cavity 1 is provided with a plurality of exhaust holes 15, so The exhaust hole 15 is used to discharge the hot air in the second wing cavity 12 . The air supply flute tube 2 is placed in the first wing chamber 11, and the high-pressure hot air flow entering from the air supply flute tube 2 is sprayed into the first wing chamber 11 at high speed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com