Digital display gradienter and machine tool guiding rail leveling method

A leveling and leveling technology, applied in instruments, mapping and navigation, measuring devices, etc., can solve the problems of high price of semiconductor laser collimators, easy accumulation of errors in measurement, and deviation of level beads from the center of the scale, etc. The effect of small precision error and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

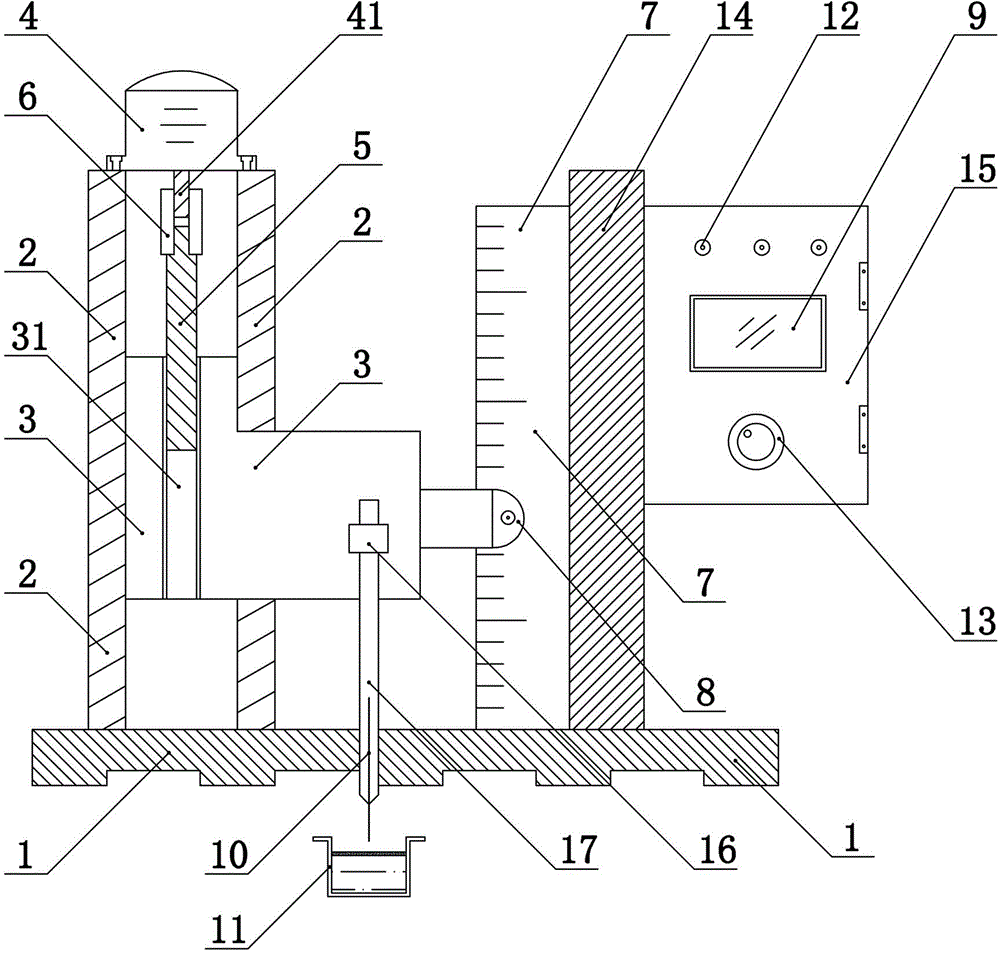

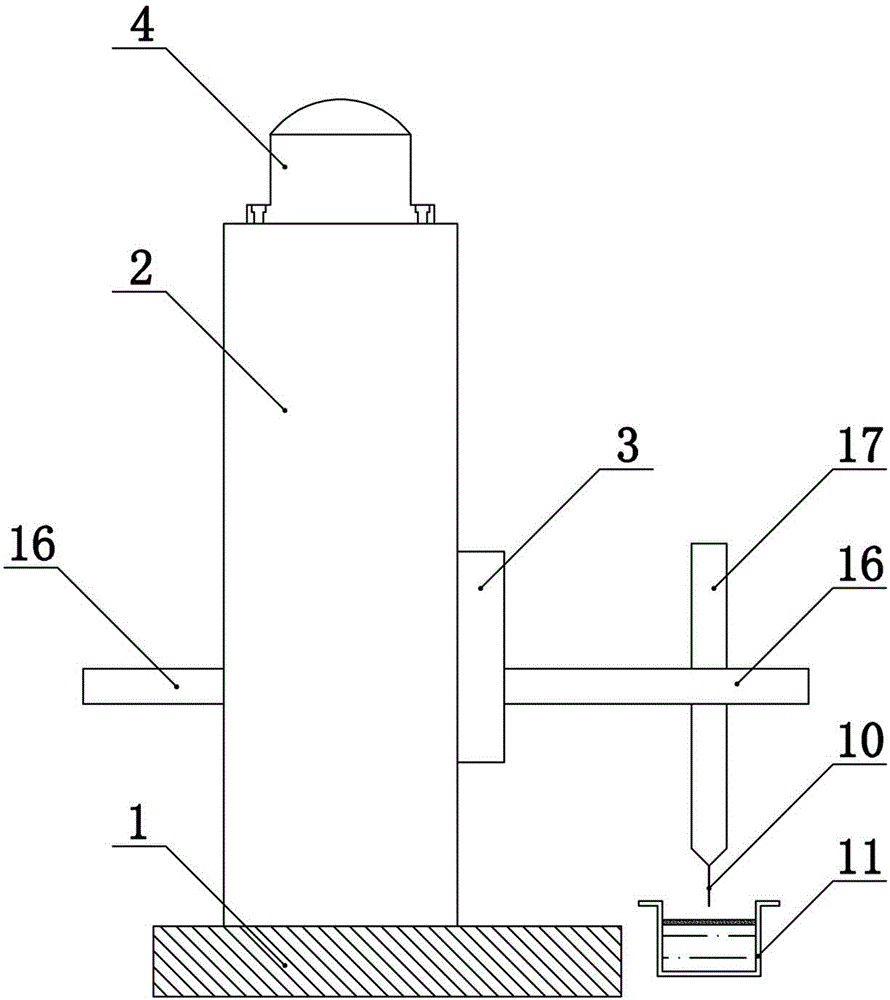

[0037] Such as figure 1 Shown, a kind of digital level, it comprises not less than a level and a water tank 11, that is, one or more level shares a water tank 11, and the same horizontal plane in the water tank 11 is used as a horizontal reference for high-precision simulation.

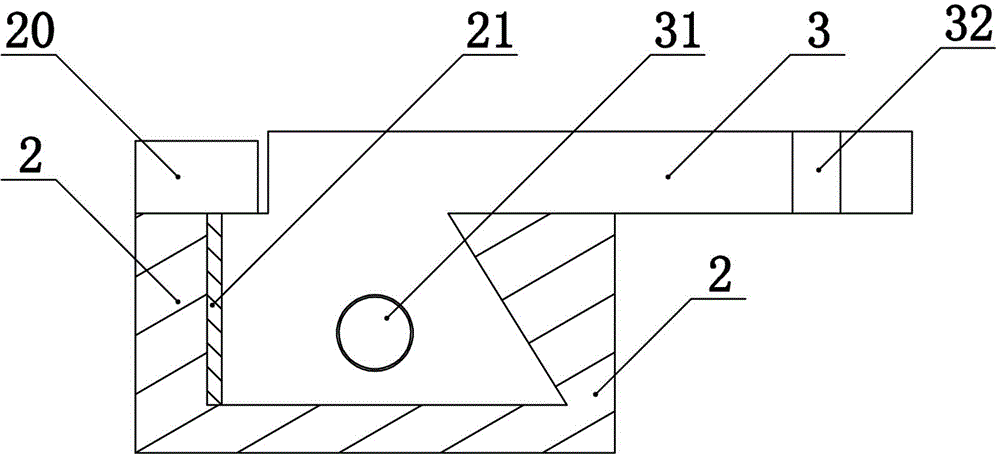

[0038] The spirit level includes a horizontal base 1, a vertical guide rail 2 arranged on the horizontal base 1, a ball screw 5 vertically arranged in the vertical guide rail 2, and a vertical guide rail 5 arranged in the vertical guide rail 2. To the sliding block 3, the stepping motor 4 installed on the top of the vertical guide rail 2, the stepping motor driver 18 electrically connected with the stepping motor 4, the hand wheel electrically connected with the stepping motor driver 18 13. Digital display grating ruler, conductive wire 10 vertically arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com