Floating ball type vibration wave sensor, as well as using method and use thereof

A sensor and vibration wave technology, applied in the field of floating ball vibration wave sensor, can solve the problems of difficulty in obtaining real-time observation results, complex underwater observation techniques and methods, and immature observation techniques for ocean internal waves and seawater vibration waves. Improve the effect of timeliness, low price and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

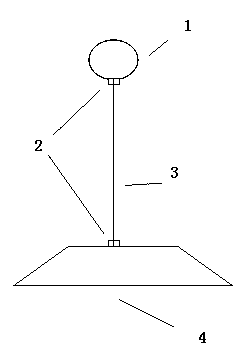

[0015] The float-type vibration wave sensor includes a low-buoyancy float 1, which is equipped with a three-axis acceleration sensor, a data acquisition and transmission integrated circuit, a temperature sensor, and a pressure sensor. The low-buoyancy float 1 is connected to a zero-buoyancy cable 3 and a watertight connector 2. The submarine network node 4 is connected.

[0016] The low buoyancy float 1 is a body made of glass, glass fiber reinforced plastic, titanium alloy, and aluminum alloy. The low buoyancy float 1 is composed of two upper and lower hemispheres. An O-shaped sealing ring is arranged between the upper and lower hemispheres. The specific gravity of the low buoyancy float 1 is adjustable, which is equivalent to 98.5% to 99.5% of the specific gravity of seawater in its environment. The specific gravity of sea water can be obtained by CTD actual measurement.

[0017] The adjustment of the specific gravity of the low buoyancy float 1 is achieved by injecting silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com