Loading and unloading basket device for silicon wafers

A silicon wafer and air blowing device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of slow loading and unloading of silicon wafers, long transmission distance, low work efficiency, etc., to shorten the movement time, reduce pollution, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

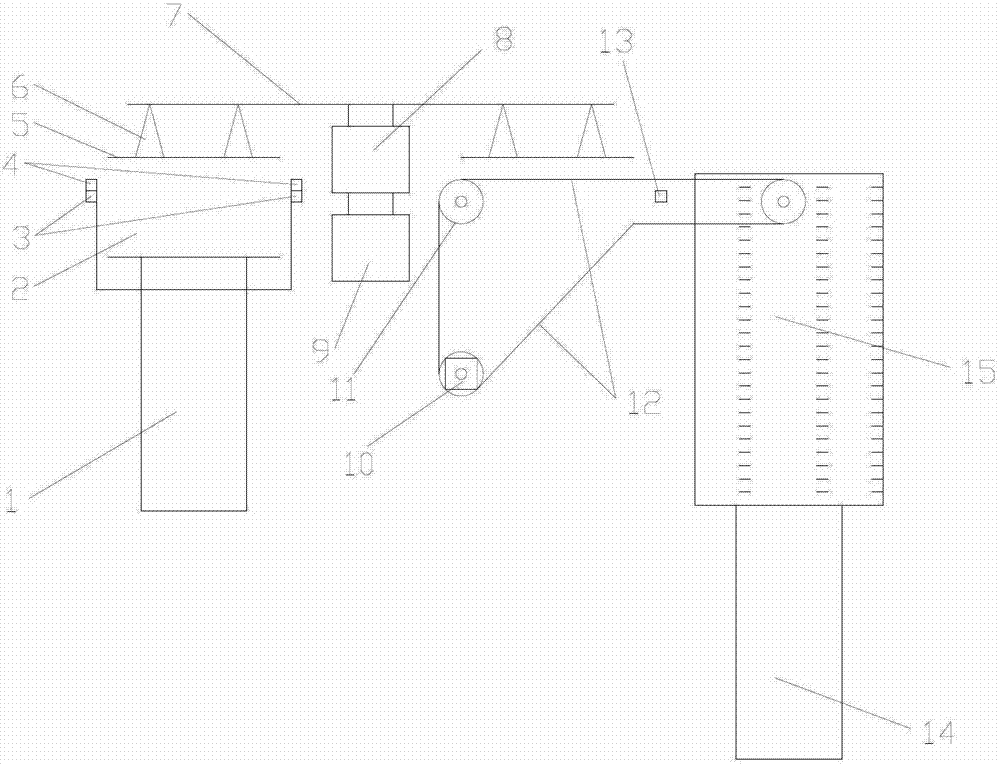

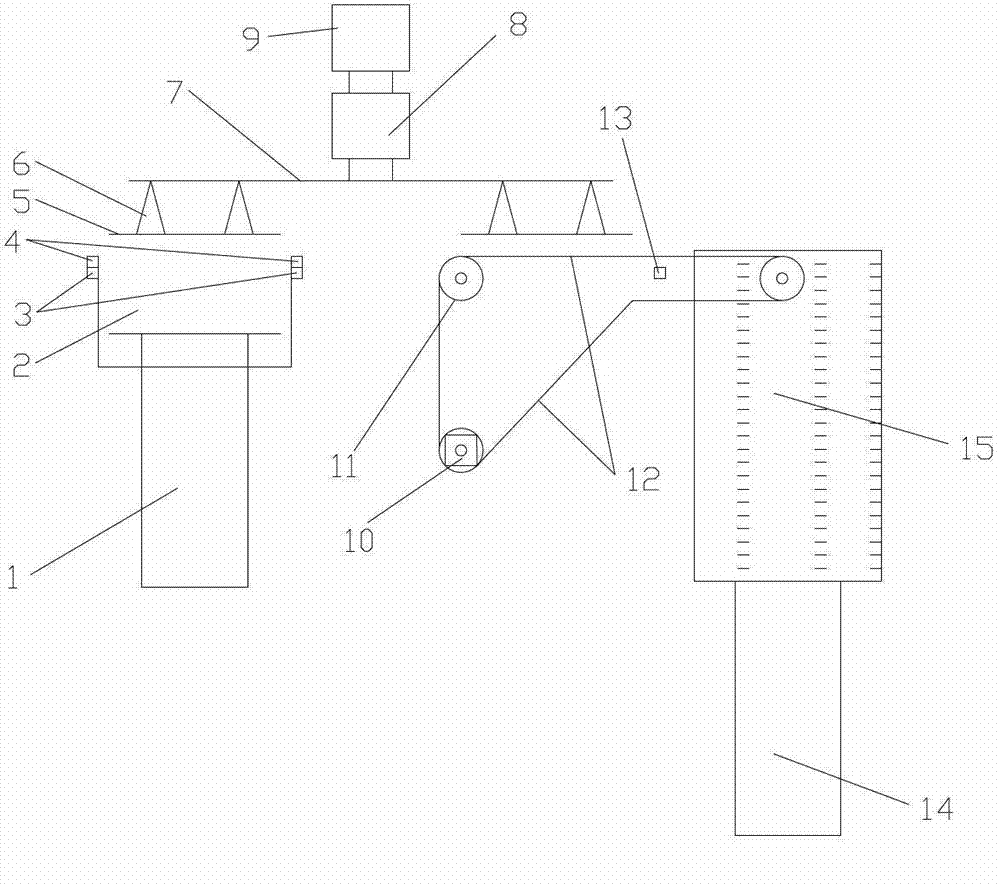

[0014] figure 1 The structure of the silicon wafer loading and unloading basket device of the present invention is schematically shown. exist figure 1 Among them, 1 is the up and down motor of the material box, 2 is the material box, 3 is the first sensor, 4 is the air blowing device, 5 is the silicon chip, 6 is the vacuum suction cup, 7 is the carbon fiber plate, 8 is the rotary cylinder, and 9 is the upper and lower cylinder , 10 is a rotary motor, 11 is a pulley, 12 is a belt, 13 is a second sensor, 14 is a flower basket motor up and down, and 15 is a flower basket.

[0015] The silicon chip loading and unloading basket device of the present invention comprises: magazine up and down motor 1, magazine 2, first sensor 3, air blowing device 4, vacuum sucker 6, carbon fiber board 7, rotary cylinder 8, upper and lower cylinder 9, rotary motor 10, Pulley 11, belt 12, second sensor 13, flower basket up and down motor 14 and flower basket 15; wherein:

[0016] Connect the stator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com