Light power optimization control system for metallic-seal radio-frequency carbon dioxide laser

A carbon dioxide and metal sealing technology, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as difficulty in meeting requirements, deviation of laser output power value, and long time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

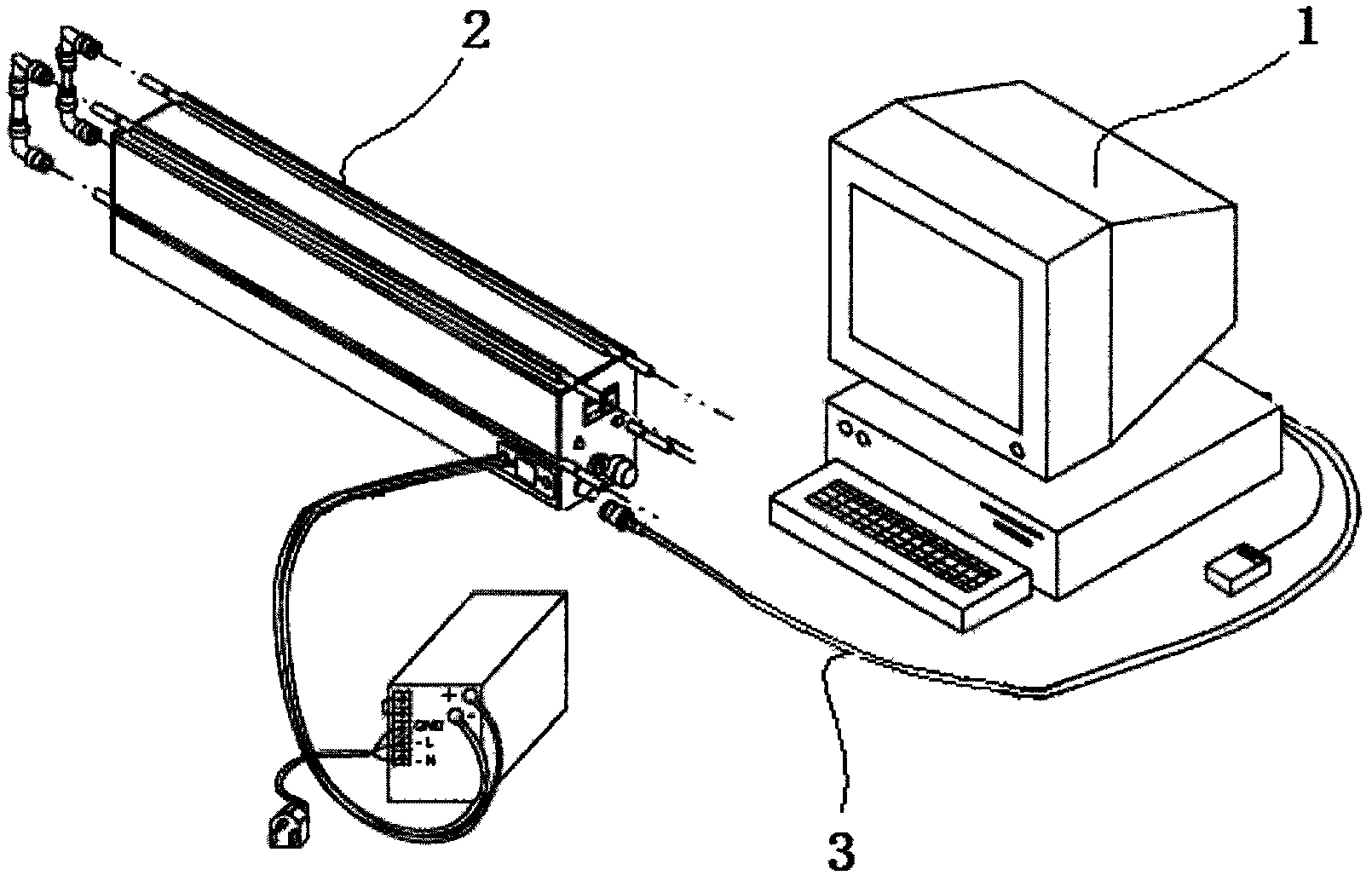

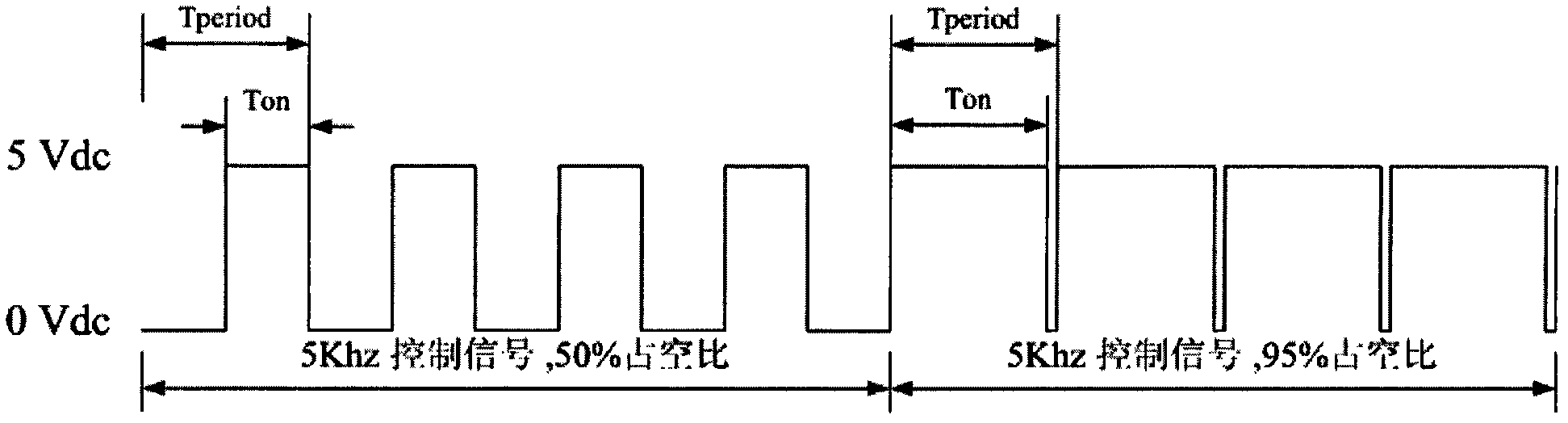

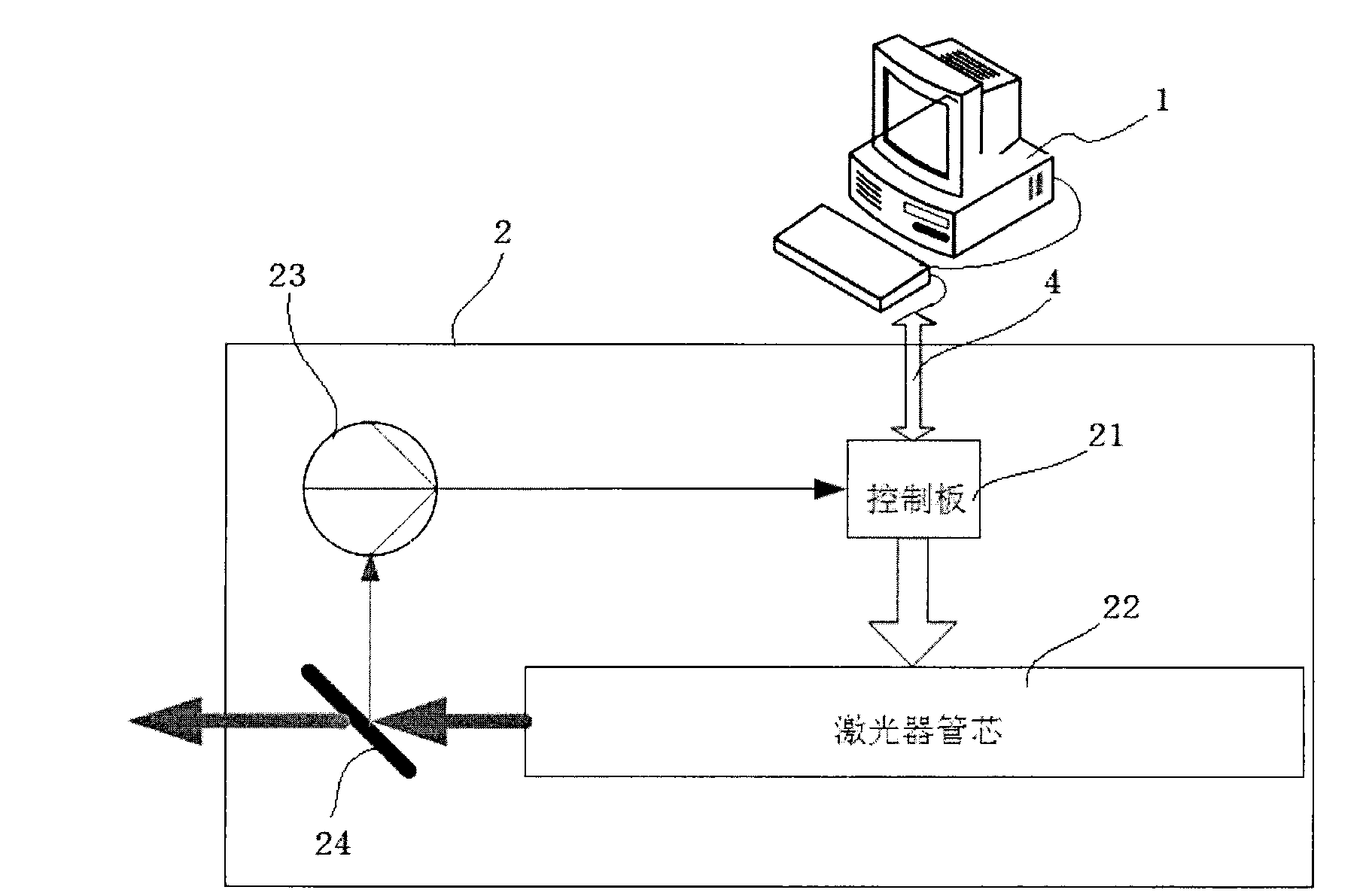

[0034] like image 3 As shown, the present invention discloses a metal-sealed radio frequency carbon dioxide laser optical power optimization control system, including a control computer and a laser, the laser includes a control board and a laser die connected to the control board, and the control computer communicates through a digital communication interface The predetermined output power value is transmitted to the control board, and the control board controls the output power of the laser die according to the predetermined output power value. For example, if the predetermined output power is 100W, the control board controls the output power of the laser die to be 100W; an embedded laser detection module is also connected to the control board, and the laser detection module tests the actual output power value of the laser die and feeds it back to the control board to dynamically adjust the actual output power of the laser die , specifically may be: a 1% spectroscope is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com