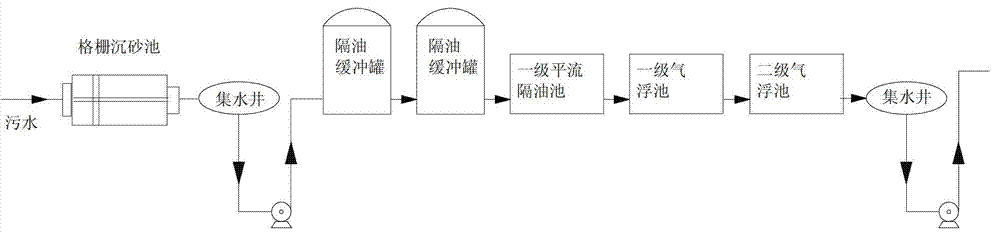

Process for pretreating refining and coal chemical oily sewage

A technology for oily sewage and coal chemical industry, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of good water quality precipitation, thorough sludge discharge and investment saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

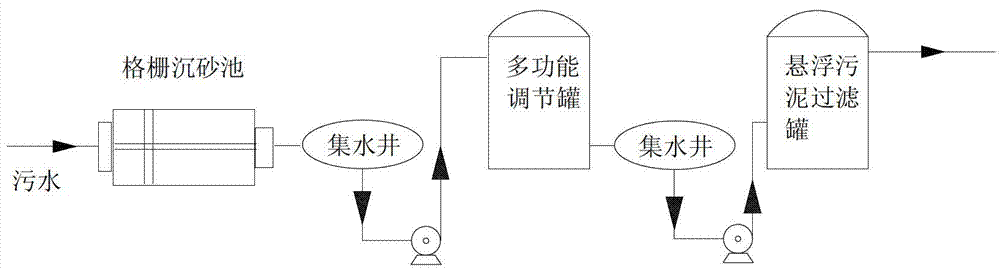

[0036] A pre-treatment process for oily wastewater from refinery and coal chemical industry: the oily wastewater first enters the grid grit chamber to remove larger debris and sand; Slick oil collection, homogenization, and sedimentation are carried out in the multi-functional regulating tank; the water from the multi-functional regulating tank enters the second water collection well, and is lifted into the suspended sludge filter tank by the secondary lifting pump; in the suspended sludge filter tank The oil and suspended solids in the sewage are removed to provide good influent water quality for subsequent biological treatment.

Embodiment 2

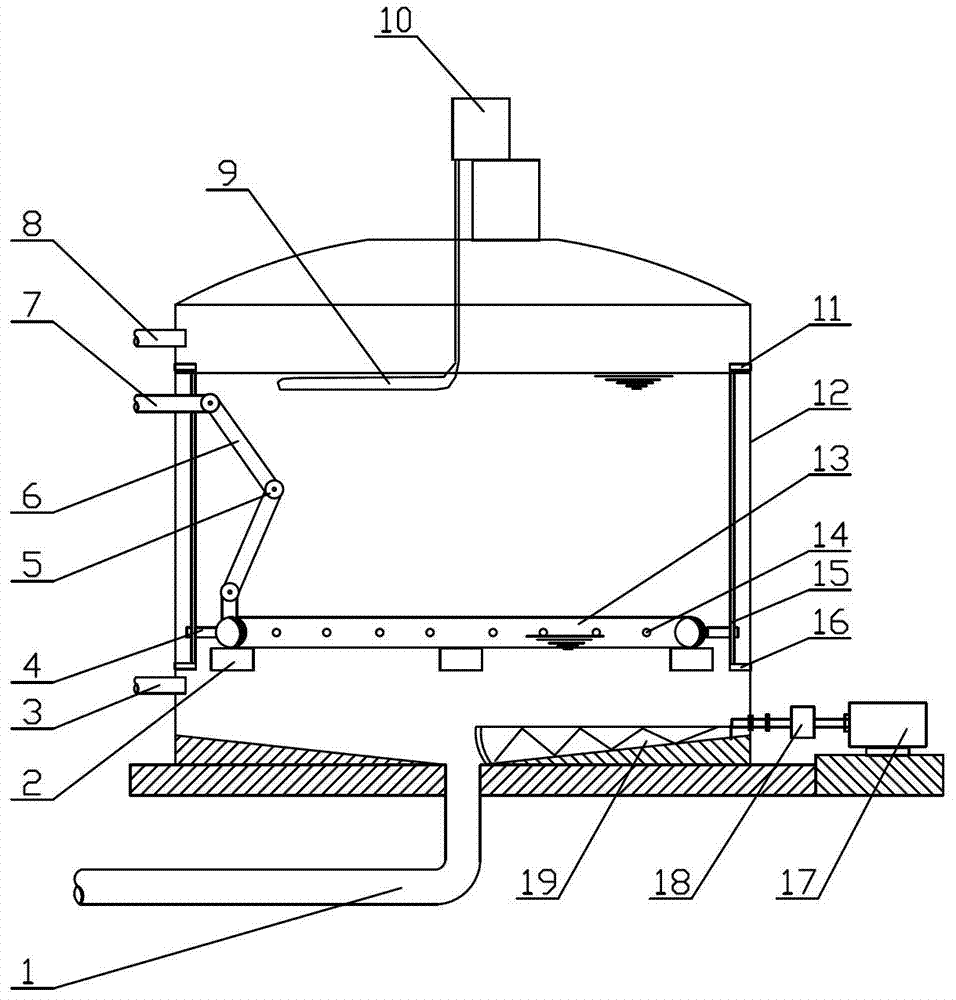

[0038] A multi-functional regulating tank, comprising a tank body 12, the tank body 12 is provided with a water inlet device 7 and a water outlet device 3, and the water inlet device 7 is connected to the inside of the tank body 12 through a multi-section conduit and a non-leakage movable joint 5. The annular floating water distribution pipe 13 is connected to each other. The annular floating water distribution pipe 13 has water outlet holes 14 at fixed intervals. The water outlet holes 14 are water distribution holes or water spray nozzles. The movable collar 4 is slidably arranged in the slide rail 15 fixed on the inner wall of the tank body. The upper end of the slide rail 15 is provided with the highest water level baffle plate 11, and the lower end is provided with the lowest water level baffle plate 16. The slide rail 15 passes through the fixing piece It is arranged on the inner wall of the tank body 12. The fixing member and the water level baffles 11 and 16 are integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com