Reduction oxidation graphene-trimanganese tetraoxide three-dimensional composite material preparation method

A technology of trimanganese tetraoxide and composite materials, which is applied in the field of preparation of reduced graphene oxide-trimanganese tetraoxide three-dimensional composite materials, can solve the problems of limiting the performance of lithium-ion positive electrode materials, uneven distribution of prepared products, and poor cycle stability. Achieve excellent electrochemical performance, low equipment requirements, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 50 mg of graphene oxide microchips, add it to 25 mL of deionized water, place it in a cell pulverizer for 0.8 h to obtain a 2 mg / ml graphene oxide dispersion, and dissolve 0.2 mmol of manganese chloride tetrahydrate into 10 mL Add the above-mentioned graphene oxide dispersion into deionized water, and stir well. Add 1mL of ammonia solution to the above mixture, and put the system into the ultrasonic reactor, give a certain degree of mechanical stirring, and ultrasonic for about 15min. The obtained system was transferred to a 50mL hydrothermal reaction kettle, reacted at 160°C for 20h, and then the product was taken out and soaked in distilled water for 3 times, 0.5h each time. The washed product was transferred to a freeze dryer for drying, and the final product was obtained after drying at -65° C. for 72 h.

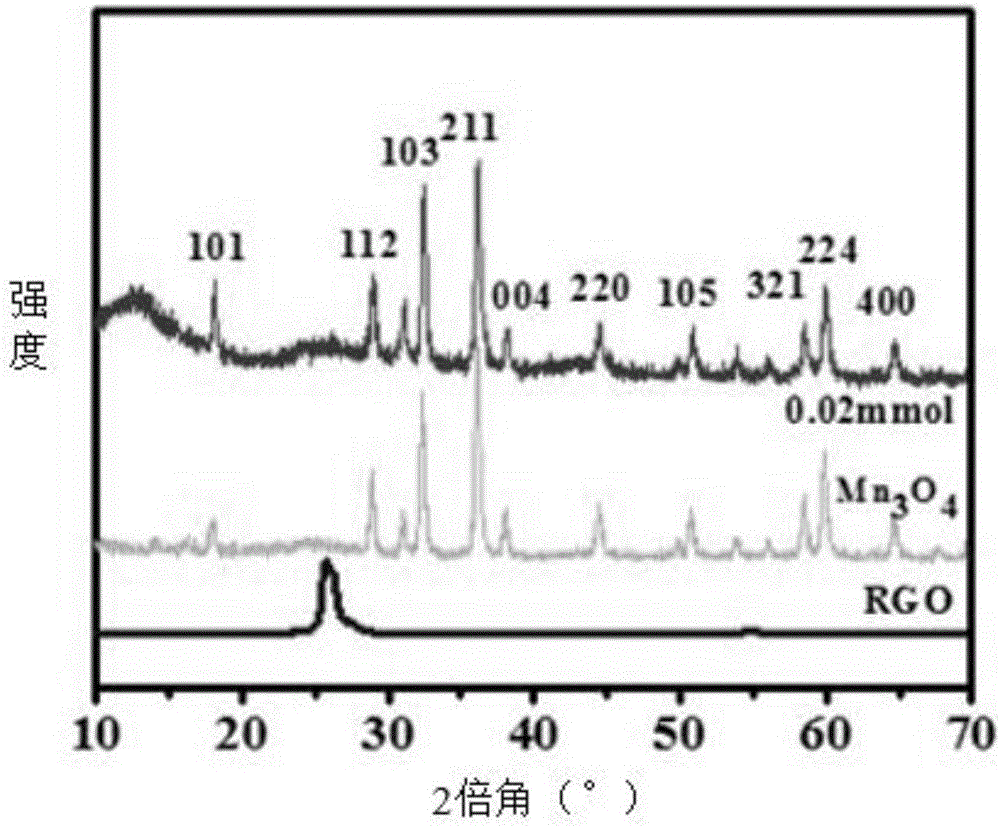

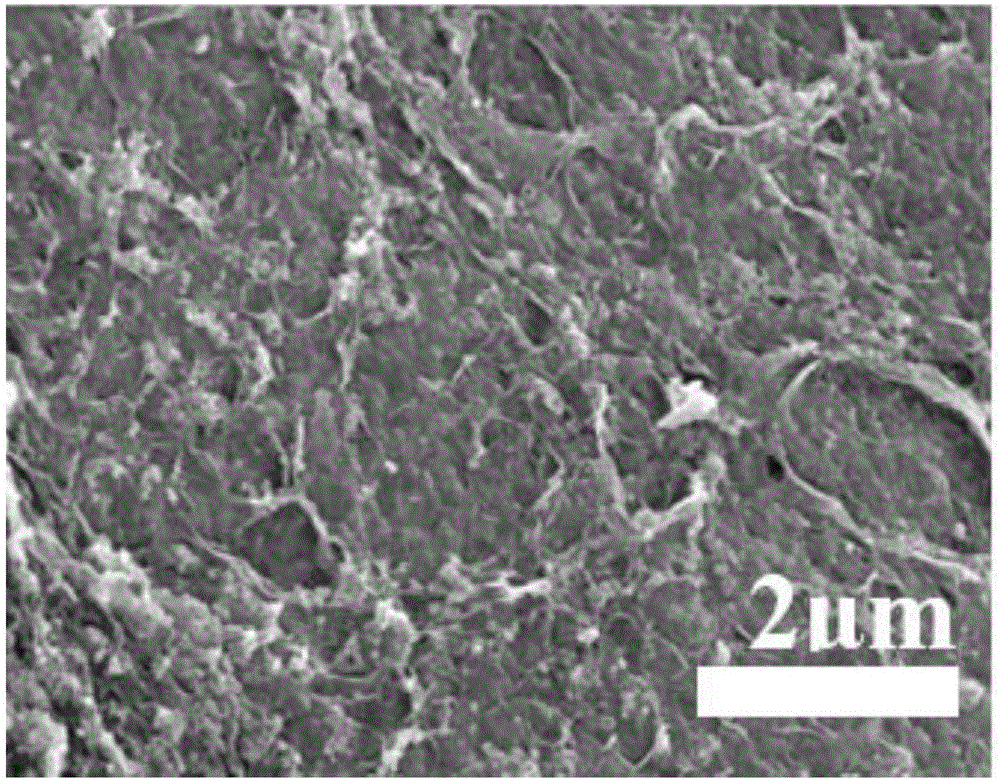

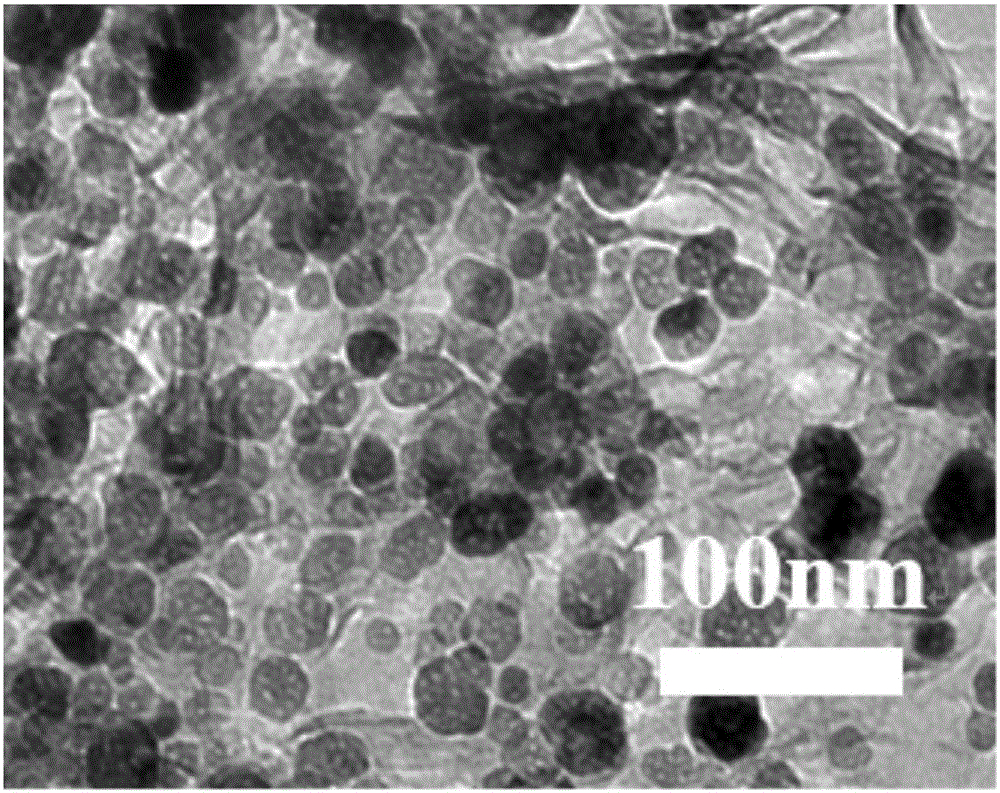

[0042] The obtained final samples were characterized by SEM, TEM and XRD, and the cycle performance test was carried out by electrochemical workstation.fig...

Embodiment 2

[0044] Weigh 40 mg of graphene oxide microchips, add them to 25 mL of deionized water, place them in a cell pulverizer for 1 hour to obtain a 1.6 mg / ml graphene oxide dispersion, and dissolve 0.1 mmol of manganese chloride tetrahydrate into 10 mL Add the above-mentioned graphene oxide dispersion into deionized water, and stir well. Add 1mL of ammonium chloride solution to the above mixture, and put the system into the ultrasonic reactor, give a certain degree of mechanical stirring, ultrasonic for about 15min, the ultrasonic power of the ultrasonic reactor is 250W. The obtained system was transferred to a 50mL hydrothermal reaction kettle, reacted at 170°C for 20h, and then the product was taken out and soaked in distilled water twice, each time for 0.6h. The washed product was transferred to a freeze dryer for drying, and the final product was obtained after drying at -70° C. for 76 h.

[0045] The obtained final samples were characterized by SEM, TEM and XRD, and the cycle ...

Embodiment 3

[0047] Weigh 60mg of graphene oxide microchips, add it to 25mL of deionized water, place it in a cell pulverizer for 1.2h, obtain a 2.4mg / ml graphene oxide dispersion, and dissolve 0.4mmol of manganese chloride tetrahydrate into 10mL deionized water, add the above graphene oxide dispersion, and stir well. Add 1mL of ammonium sulfate solution to the above mixture, and put the system into the ultrasonic reactor, give a certain degree of mechanical stirring, ultrasonic for about 23min, the ultrasonic power of the ultrasonic reactor is 250W. The obtained system was transferred to a 50 mL hydrothermal reaction kettle, reacted at 200°C for 20 h, and then the product was taken out and soaked in distilled water for 4 times, 0.4 h each time. The washed product was transferred to a freeze dryer for drying, and the final product was obtained after drying at -80° C. for 72 h.

[0048] The obtained final samples were characterized by SEM, TEM and XRD, and the cycle performance test was ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com