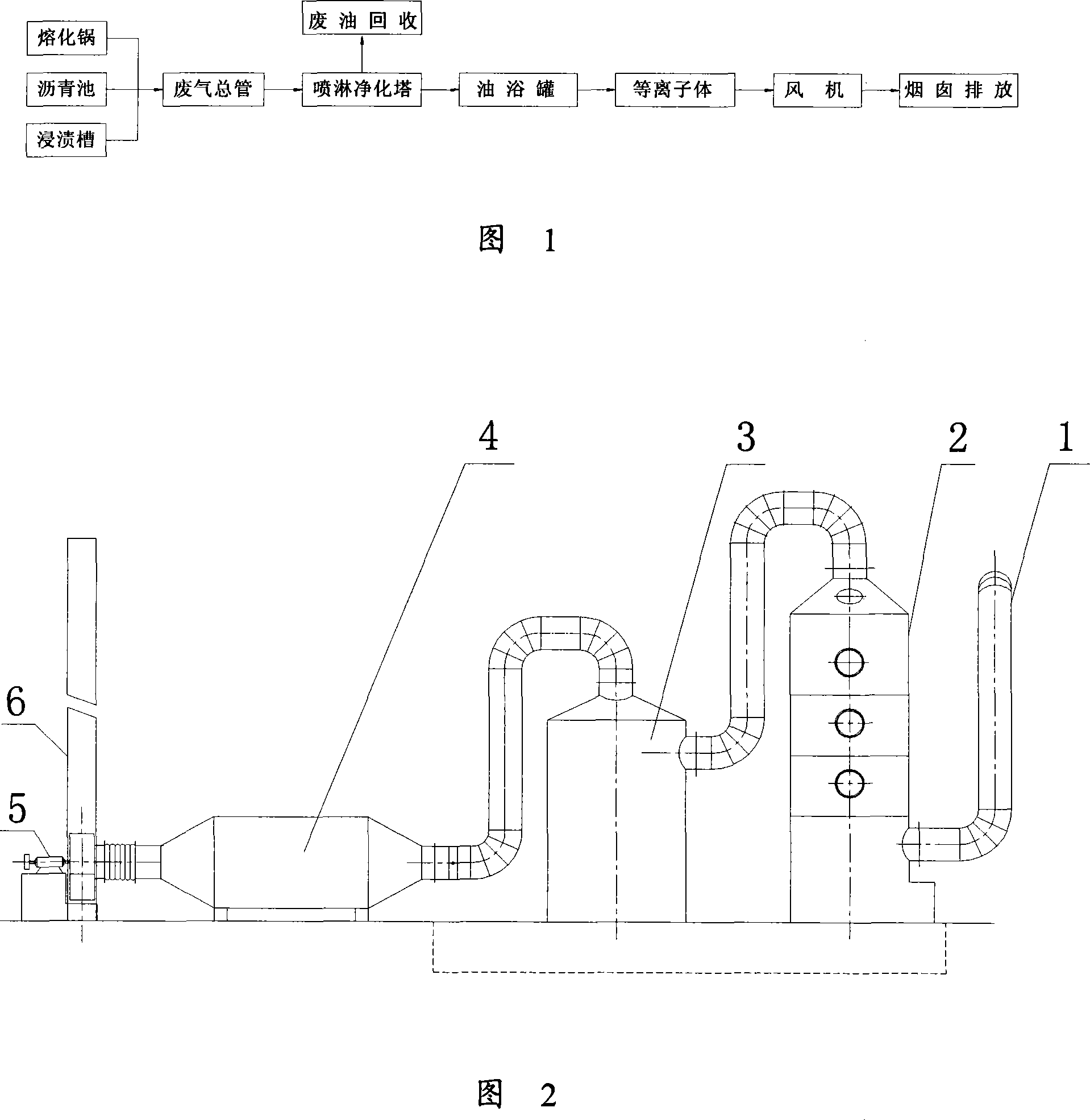

Method and device for fathering bitumen waste gases

A waste gas treatment and waste gas technology, applied in separation methods, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of difficult to scrape asphalt, increased energy consumption, and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An enterprise in Zhejiang has ten sets of asphalt melting pots, two sets of waterproof membrane manufacturing equipment, two asphalt melting tanks, and one dipping tank. The daily asphalt consumption is about 20 tons, mainly 10# and 100# asphalt.

[0039] According to the environmental impact assessment and on-site investigation, the total treatment capacity of the exhaust gas treatment system is 16000Nm 3 / h, the specific design parameters are determined as follows:

[0040] (1) Melting pot: exhaust gas volume: 1200Nm 3 / h. Taiwan, a total of 12000Nm 3 / h.

[0041] (2) Asphalt pool: exhaust gas volume: 750Nm 3 / h. only, a total of 1500Nm 3 / h.

[0042] (3) Dipping tank: exhaust gas volume: 1000Nm 3 / h+1500Nm 3 / h=2500Nm 3 / h

[0043] The discharge of pollutants complies with the emission standards required by the secondary standards in "Emission Standards for Odor Pollutants)" (GB14554-93) and "Integrated Emission Standards for Atmospheric Pollutants" (GB16297-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com