Phosphor composition and fluorescent lamp tube

A technology of composition and fluorescent powder, which is applied in the direction of luminescent materials, parts of gas discharge lamps, chemical instruments and methods, etc., can solve the problems of large visual distortion, high color temperature, and strong light, and achieve color without distortion, visual The effect of reducing material fatigue and improving color deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

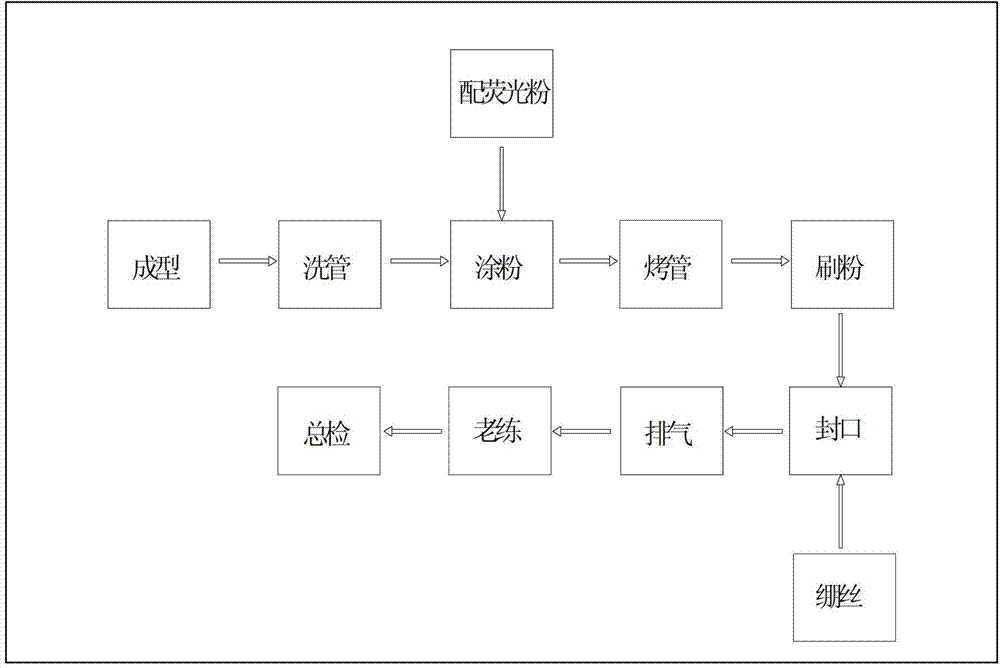

[0031] The main steps are as follows (process flow chart see figure 1 ):

[0032] ⑴Forming

[0033] Will The lead-free glass straight pipe with the pipe diameter is cut to the required length, and then bent into shape by the forming machine. The temperature of the forming machine must reach the softening temperature of the lead-free glass tube during bending, and the setting temperature of the forming machine is 850~900°C.

[0034] ⑵ washing tube

[0035] Clean the bent glass surface tube to remove the broken glass and dirt remaining during the bending process, clean it with ultrasonic machinery and boiling hot water, dry it and wait for powdering for later use.

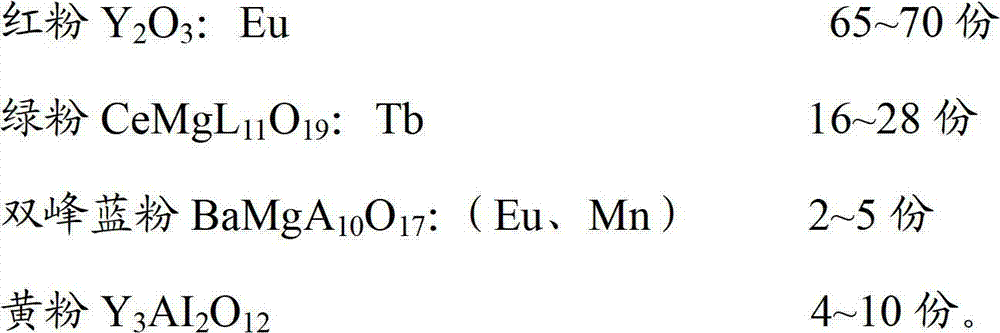

[0036] ⑶ with 2500K fluorescent powder paste

[0037] Phosphor powder formula (the phosphor powder was purchased from Jiangmen Keheng Industrial Co., Ltd.):

[0038] Pink Y 2 o 3 : Eu 70 parts

[0039] Green powder CeMgL 11 o 19 : Tb 28 servings

[0040] Yellow powder Y 3 AI 2 o 12 5 copies ...

Embodiment 2

[0063] The main steps are as follows:

[0064] (1) Forming

[0065] Will The lead-free glass straight pipe with the pipe diameter is cut to the required length, and then bent into shape by the forming machine. The temperature of the forming machine must reach the softening temperature of the lead-free glass tube during bending, and the setting temperature of the forming machine is 850~950°C.

[0066] (2) washing pipe

[0067] Clean the bent glass surface tube to remove the broken glass and dirt remaining during the bending process, clean it with ultrasonic machinery and boiling hot water, dry it and wait for powdering for later use.

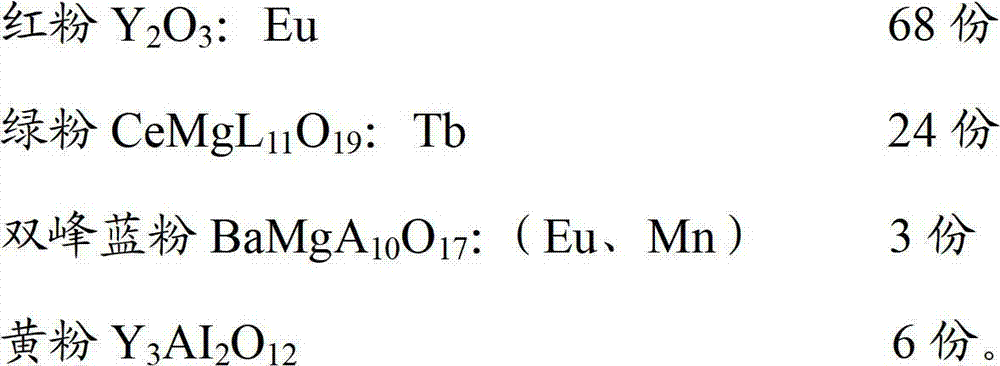

[0068] (3) With 2500K phosphor powder paste

[0069] Phosphor powder formula (the phosphor powder was purchased from Jiangmen Keheng Industrial Co., Ltd.):

[0070]

[0071] The preparation of binder solution, surfactant solvent and surfactant solvent is the same as in Example 1.

[0072] Add 1250ml of deionized water, 5kg of fluorescen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com