Multiphase flow regulation device and method for restraining slug flow by utilizing same

A flow adjustment and multiphase flow technology, which is applied in the fields of production fluids, earthwork drilling, drilling equipment, etc., can solve the problems of constant underwater installation and maintenance, limited bending radius, and difficulty in stable placement, and achieves reasonable device structure and implementation. Simple, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

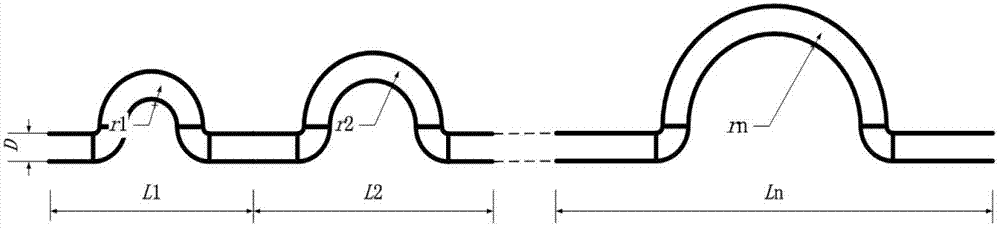

[0053] Such as Figure 1~4 As shown, the present invention provides a multiphase flow adjustment device, comprising:

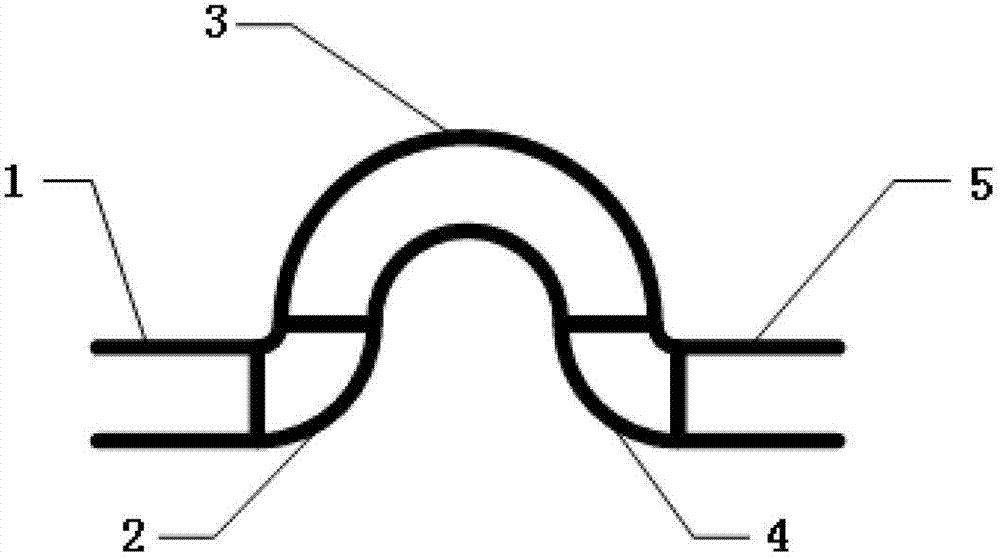

[0054] At least one basic unit, such as figure 1 , 2 As shown, the basic unit includes:

[0055] The front straight pipe section 1 and the rear straight pipe section 5 are provided with a main elbow 3 protruding upwards between the two, and the main elbow 3 is a 180° elbow,

[0056] The main elbow 3 and the front straight pipe section 1 are connected through the front elbow 2,

[0057] The main bend pipe 3 and the back straight pipe section 5 are connected by a back bend 4,

[0058] Both the front elbow 2 and the rear elbow 4 are 90° elbows.

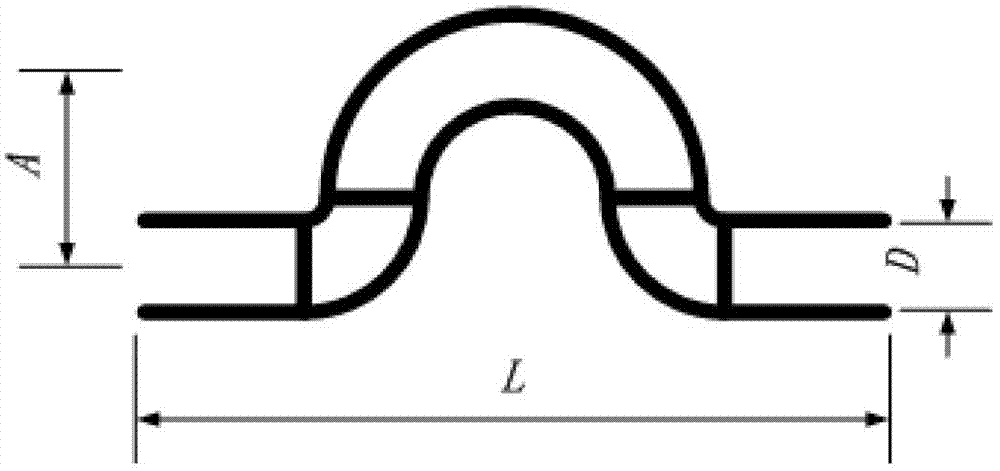

[0059] Such as figure 2 As shown, let the distance between the axis of the straight pipe section and the centerline of the top of the main bend be the amplitude A of the basic unit, the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com