Fully-enclosed suspension type multistage centrifugal pump for transporting high-pressure freon

A freon, fully enclosed technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve problems such as unsatisfactory, low transmission efficiency of magnetic coupling, static seal leakage, etc., to reduce production costs, Effect of eliminating transmission loss and solving leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

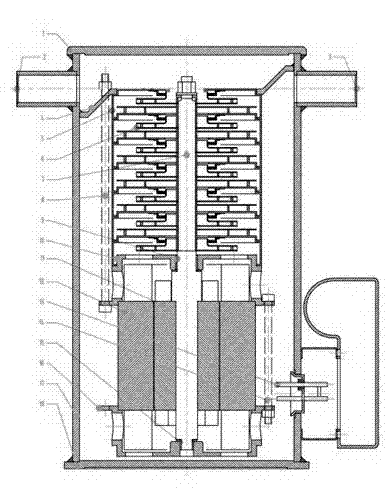

[0017] like figure 1 As shown, a fully enclosed suspended multistage centrifugal pump for conveying high-pressure Freon, including a pump cover, a sleeve, an inlet pipe, an outlet pipe, a base, a sealing terminal, a partition, a multistage impeller, a multistage guide vane body, Shaft, upper bearing seat, lower bearing seat, upper bearing, lower bearing and fluorine-resistant motor. The pump cover, sleeve, inlet pipe, outlet pipe, base and sealing terminal are welded to form a fully-enclosed airtight casing that can withstand high pressure; partitions, multi-stage impellers, multi-stage guide vanes, shafts, and upper bearing seats , the lower bearing seat, the upper bearing, the lower bearing, and the fluorine-resistant motor including the stator and the rotor form the inner core of the pump set. The inner core is suspended under the partition and completely placed in a fully enclosed sealed casing. The pump has neither dynamic seal nor static sealing surface, which completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com