Method for adjusting clearance of bearing at upper part of heavy loaded planetary reducer of coal cutter cutting unit

A technology of shearer cutting part and planetary reducer, which is applied to mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of oil leakage of floating seals, and achieve easy installation, good effect, and adjustment value accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

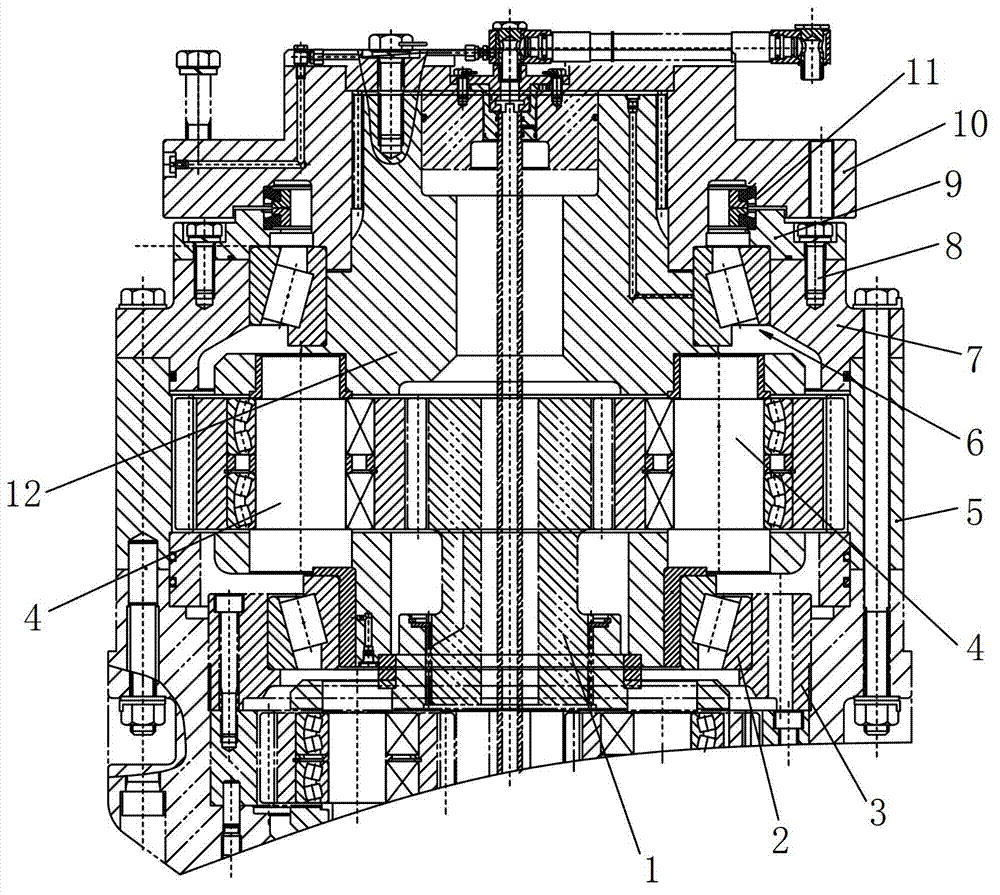

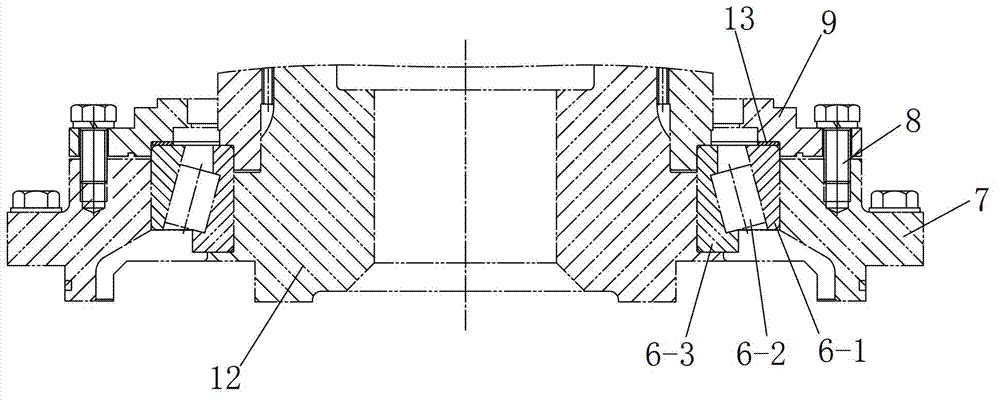

[0036] Such as figure 1 , figure 2 with image 3 Shown is a method for adjusting the upper bearing clearance of a heavy-duty planetary reducer in the cutting part of a coal mining machine. The heavy-duty planetary reducer includes an inner ring gear 5 fixedly installed on the cutting part of the The sun gear 1 and the planet carrier 12 on the coal machine cutting section, the planet carrier 12 is equipped with a plurality of planetary gears 4 arranged around the sun gear 1, and the sun gear 1 is meshed with a plurality of planetary gears 4, so The inner ring gear 5 is meshed with a plurality of planetary gears 4 located inside it, and a bearing seat 3 is provided on the cutting part of the shearer and at the lower part of the planet carrier 12, and a bearing seat 3 is provided on the bearing seat 3. The first tapered roller bearing 2 matching the planet carrier 12, the upper part of the ring gear 5 is provided with a bearing seat 2 7, and the bearing seat 2 7 is provided wi...

Embodiment 2

[0051] Such as figure 1 , figure 2 with image 3 As shown, another heavy-duty planetary reducer in the cutting part of the coal shearer is selected as the adjustment object. The structure and shape of the heavy-duty planetary reducer are the same as those described in Embodiment 1.

[0052] The difference between this embodiment and Embodiment 1 is that, when the tapered roller bearing 2 6 is under the condition of no load, the method for adjusting the clearance of the tapered roller bearing 2 6 includes the following steps:

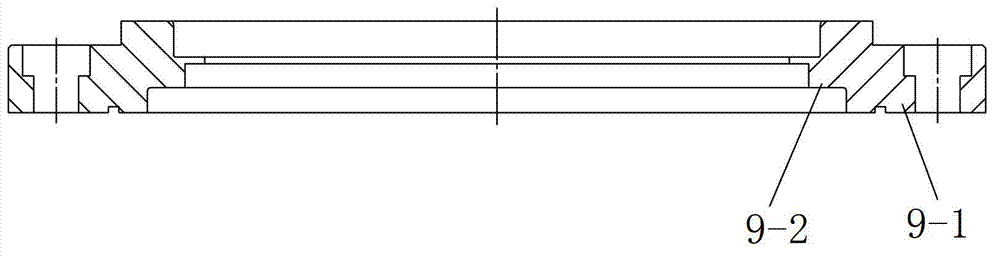

[0053] Step 1. Install the sealing cover: Install the sealing cover 9 on the bearing seat 2 7, the sealing cover 9 is circular, and the sealing cover 9 includes the connecting ring 1 9-1 and The second connecting ring 9-2 matching the outer ring 6-1 of the tapered roller bearing 6, the first connecting ring 9-1 and the second connecting ring 9-2 are integrally formed, and the second connecting ring 9-2 2 and the outer ring 6-1 are provided with a rig...

Embodiment 3

[0064] Such as figure 1 , figure 2 with image 3 As shown, another heavy-duty planetary reducer in the cutting part of the coal shearer is selected as the adjustment object. The structure and shape of the heavy-duty planetary reducer are the same as those described in Embodiment 1.

[0065] The difference between this embodiment and Embodiment 1 is that, when the tapered roller bearing 2 6 is under the condition of no load, the method for adjusting the clearance of the tapered roller bearing 2 6 includes the following steps:

[0066] Step 1. Install the sealing cover: Install the sealing cover 9 on the bearing seat 2 7, the sealing cover 9 is circular, and the sealing cover 9 includes the connecting ring 1 9-1 and The second connecting ring 9-2 matching the outer ring 6-1 of the tapered roller bearing 6, the first connecting ring 9-1 and the second connecting ring 9-2 are integrally formed, and the second connecting ring 9-2 2 and the outer ring 6-1 are provided with a rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com