Hydraulic filling type central air-conditioning unit

A central air-conditioning, flooded technology, applied in the direction of refrigerators, heating methods, refrigeration components, etc., can solve the problems of unit evaporator freezing, shortening the service life of the unit, and losing the function of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

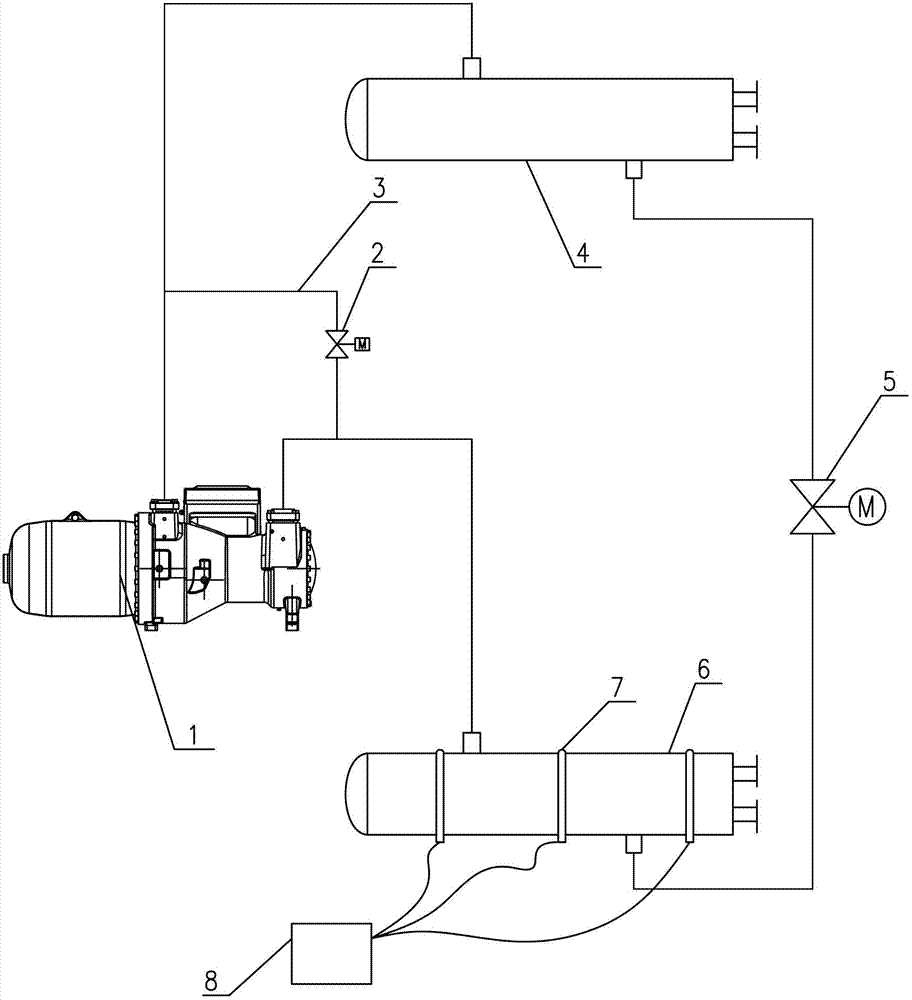

[0019] Such as figure 1 As shown, a flooded central air-conditioning unit includes a compressor 1, a condenser 4, an expansion valve 5, an evaporator 6 and a control unit for controlling the operation of the unit, and the outlet of the compressor 1 is connected to the outlet of the condenser 4 Refrigerant inlet, the refrigerant outlet of the condenser 4 is connected to the inlet of the expansion valve 5, the outlet of the expansion valve 5 is connected to the refrigerant inlet of the evaporator 6, and the refrigerant outlet of the evaporator 6 is connected to The inlet of the compressor 1 also includes a bypass pipeline 3 that passes the high-pressure refrigerant in the condenser 4 into the evaporator 6, and one end of the bypass pipeline 3 is connected to the outlet of the compressor 1 and On the pipe between the refrigerant inlet of the condenser 4, the other end is connected to the pipe between the inlet of the compressor 1 and the refrigerant outlet of the evaporator 6, an...

Embodiment 2

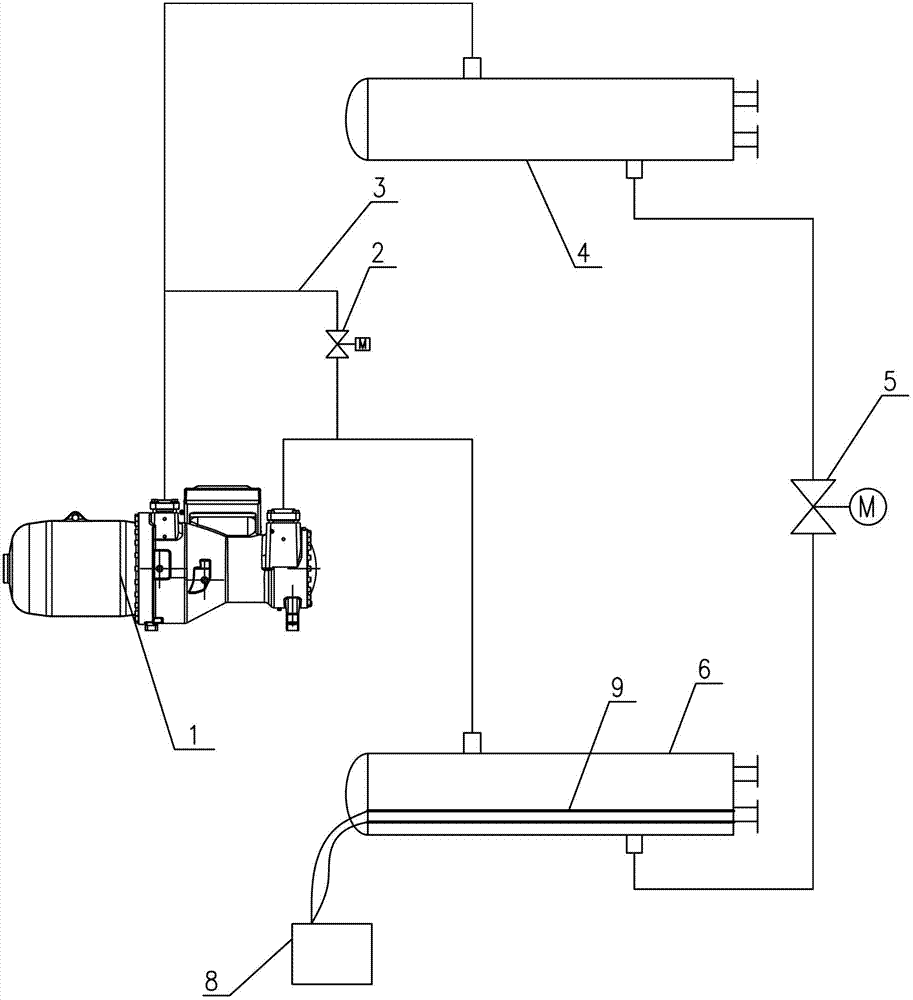

[0024] Such as figure 2 As shown, the difference between embodiment two and embodiment one is that the strip electric heater 9 installed in the evaporator 6 is used instead of the annular electric heater, and the strip electric heater 9 is directly connected to the evaporator 6 The water inside is heated by contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com