High-temperature high-pressure in-situ high-speed scratching device

A high-temperature, high-pressure, high-speed technology, which is applied in the field of surface scratching of corrosion-resistant materials, can solve problems such as in-situ high-speed scratching and scratching sample fixation, pressure balance and sealing of insulating high-speed moving shafts, etc., so as to facilitate quantitative comparison, Easy disassembly and maintenance, fast scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

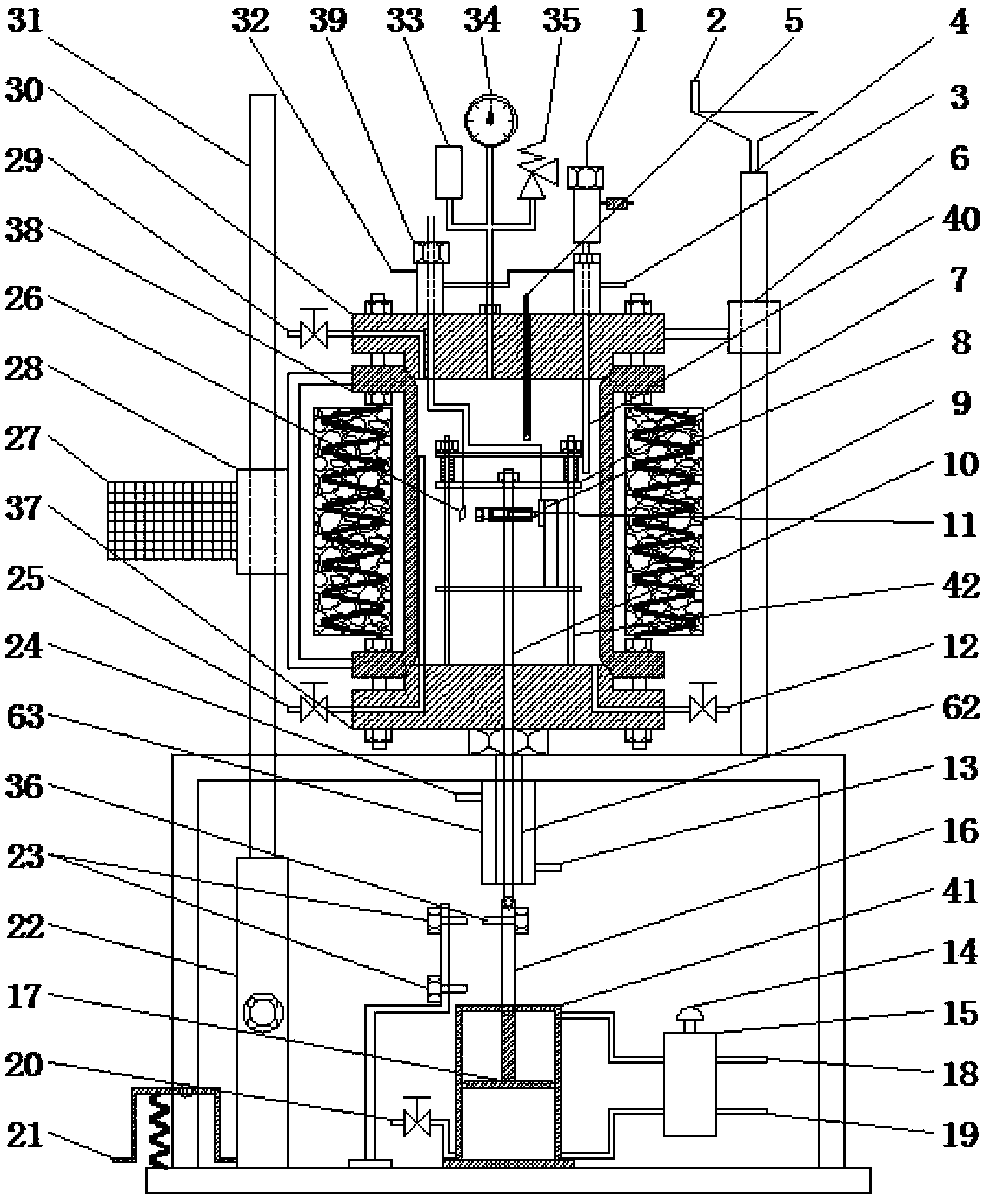

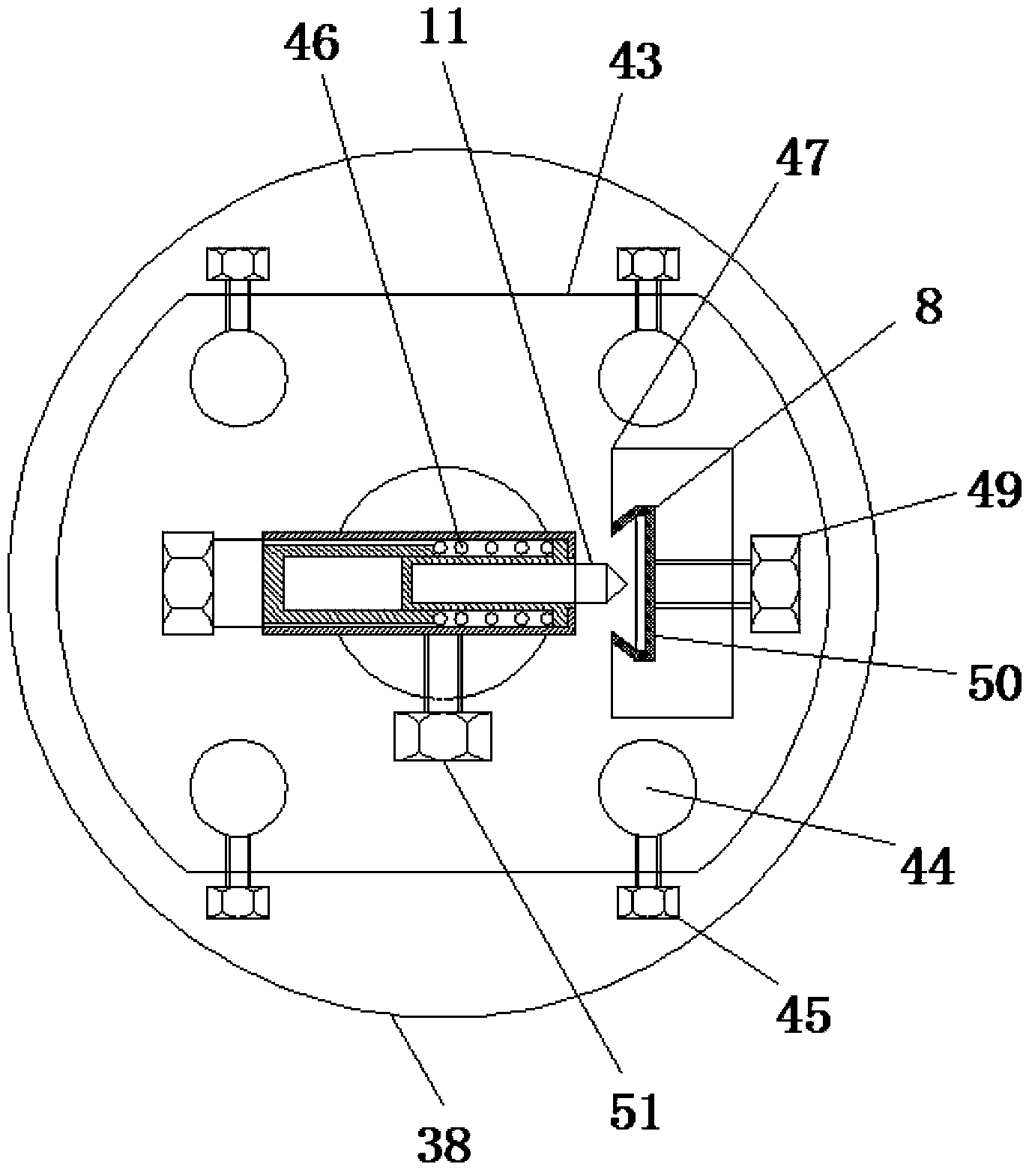

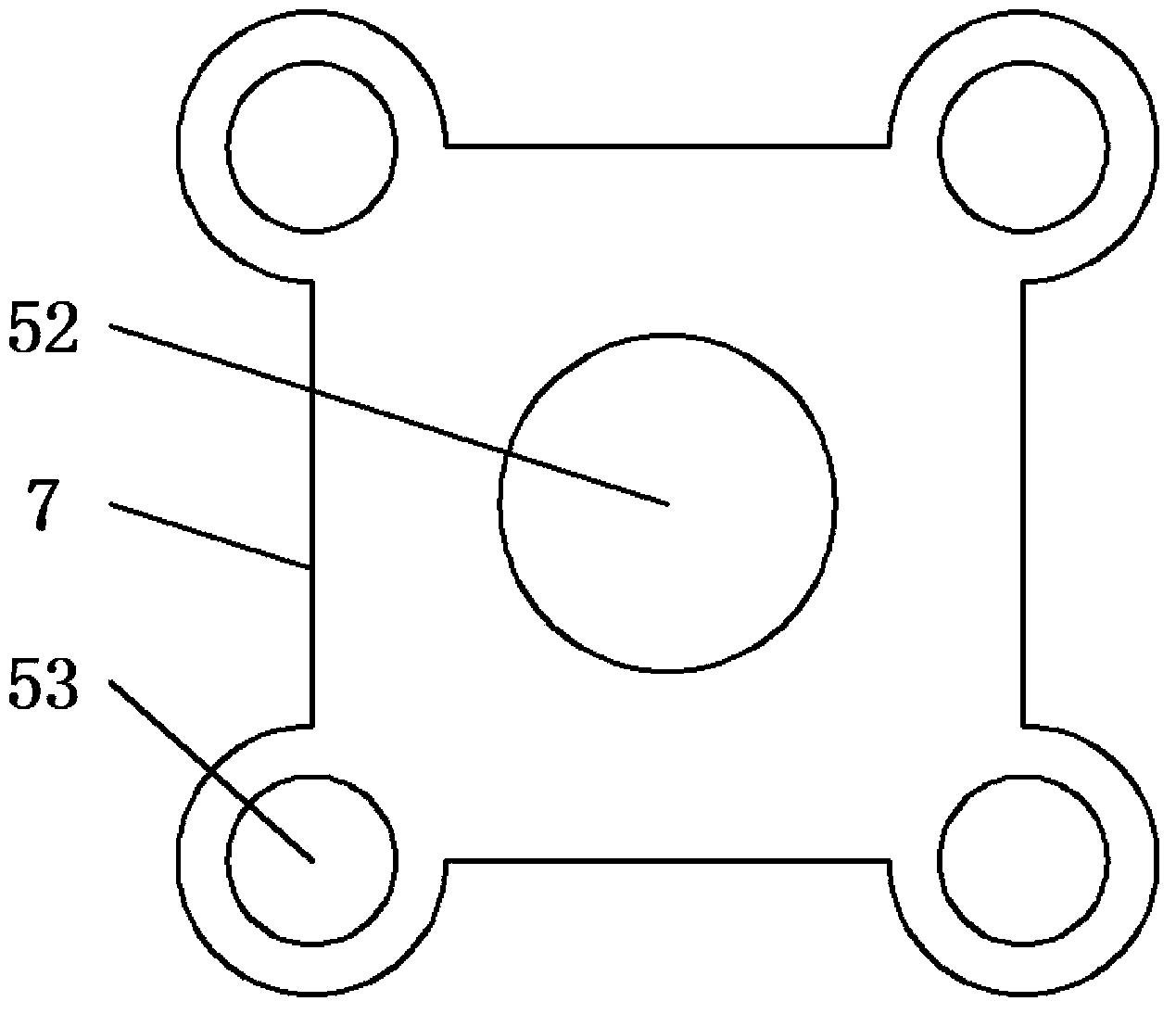

[0037] Such as Figure 1-Figure 4 As shown, the high-temperature, high-pressure in-situ high-speed scratching device of the present invention is provided with: a reference electrode 1, a manual lifting plate 2, an electrode cooling water inlet 3, a column II 4, a thermocouple 5, a slider II 6, a guide plate 7, Working electrode (sample) 8, ring heater 9, high-speed motion shaft 10, stroke head 11, intake valve 12, high-speed motion shaft cooling water inlet 13, reversing valve switch 14, reversing valve 15, pneumatic piston rod 16. Piston 17, air inlet 18, exhaust port 19, air release valve 20, pedal 21, hydraulic cylinder 22, Hall sensor 23, high-speed motion shaft cooling water outlet 24, liquid inlet valve 25, auxiliary electrode 26, distribution Weight 27, slider Ⅰ 28, autoclave exhaust valve 29, upper autoclave cover 30, column Ⅰ 31, electrode cooling water outlet 32, pressure transmitter 33, pressure gauge 34, safety valve 35, magnetic steel 36, lower autoclave Cover 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com