Automatic LED (light-emitting diode) display screen correction method

A technology of LED display screen and calibration method, applied in static indicators, signal transmission systems, instruments, etc., can solve the problems of inability to complete calibration work, waste of human resources, complicated calibration process, etc., to save manpower, improve accuracy, Reduce the effect of the information exchange process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

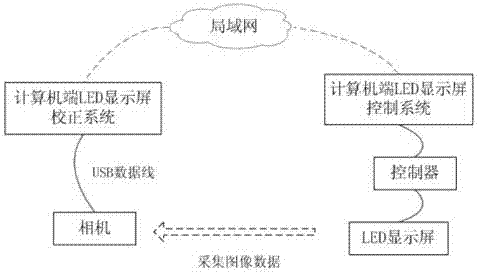

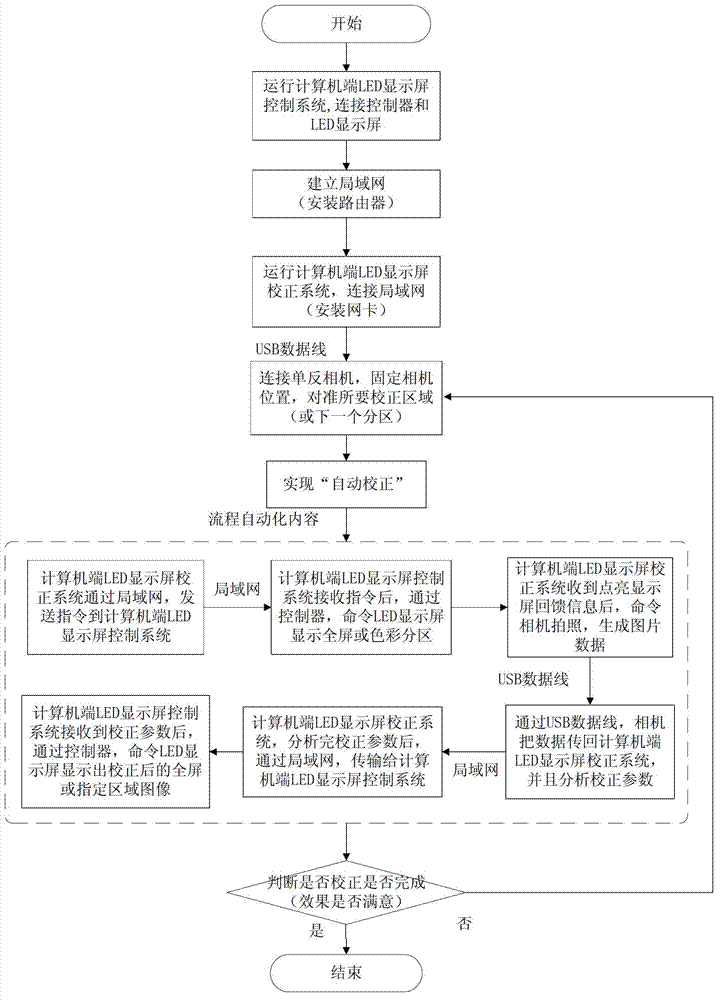

[0030] Such as figure 1 As shown, the system structure of the LED of the present invention is mainly composed of a computer-side LED display correction system (A-side) and a computer-side LED display control system (B-side) for establishing a network connection (taking a wireless local area network as an example). The LED display screen is equipped with an image acquisition device (SLR camera is preferred), the lens points to the LED display screen, the lens covers the full LED screen, and can be aimed at a certain partition of the LED display screen as required. The image acquisition equipment can collect the image information of the LED display with high quality, and transmit it to the correction system through the USB data cable. The correction coefficient calculation module in the correction system sends the calculated correction coefficient to the control system of the LED display through the network connection. Thereby adjusting the configuration parameters of the LED di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com