Light spot suppression method in bright field defect scanning

A defect scanning and spot technology, which is applied in the field of spot suppression, can solve the problems of affecting the collection of reflected light, unpredictable spot shape, and reducing scanning sensitivity, etc., to achieve the effects of ensuring scanning sensitivity, suppressing impact, and improving scanning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

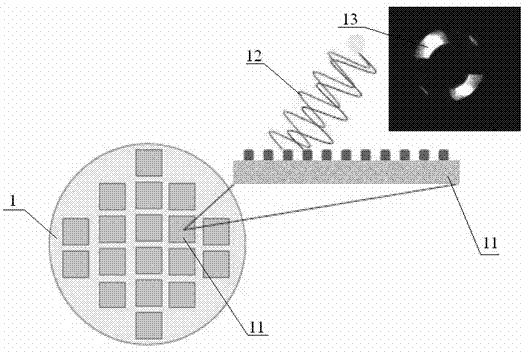

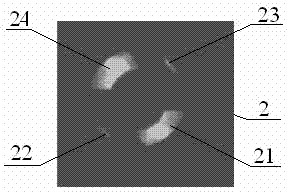

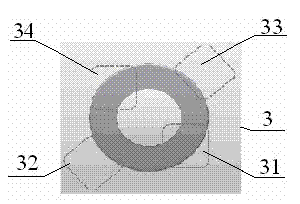

[0021] Figure 2-4 It is a schematic flowchart structure diagram of an embodiment of a method for suppressing light spots in bright field defect scanning according to the present invention.

[0022] Such as Figure 2-4 As shown, first, a semiconductor device is prepared, and when the defect scanning process is performed on it, the light spot analysis system (lobes collection) is used to collect and analyze the information of the light spot generated by the semiconductor device on the bright field defect detection machine, Obtaining the shape and position of the light spots that can be formed on the surface of the semiconductor device; then, using a light spot pattern conversion system (lobes image mode) to convert the information of the collected light spots into a light spot pattern 2, wherein the light spot pattern 2 includes the first light sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com