A Dynamic Electroluminescent Wire with Gradient Brightness

A technology of electroluminescent wire and electroluminescent material, which is applied in the direction of electroluminescent light source, electric light source, light source, etc., and can solve the problems that the change of luminous light intensity cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

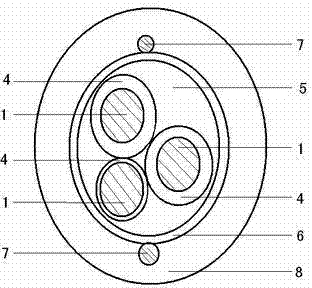

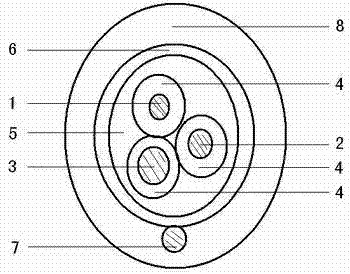

[0044] A round copper wire with a diameter of 0.12 mm is selected as the core wire electrode, and the number of core wire electrodes is 9.

[0045] The insulating layer is made by mixing and coating the dielectric material barium titanate and epoxy resin adhesive; the ratio between the dielectric material and the adhesive is about 1:1, and it is heated, dried and cured. The thicknesses of the outer coating insulation layers of the nine core wire electrodes are 0.03mm, 0.06mm, 0.09mm, 0.12mm, 0.15mm, 0.18mm, 0.21mm, 0.24mm, and 0.27mm, and the average spacing is 0.03mm.

[0046] 9 wires coated with insulating layer are twisted and twisted and arranged regularly to form a multi-strand wire, and then coated with a luminous layer on the surface.

[0047] The electroluminescent material layer is made by mixing and coating electroluminescent material D512 and epoxy resin adhesive. The ratio between electroluminescent material and adhesive is about 1:1, and it is heated, dried and cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com