Torque ripple suppression control apparatus and torque ripple suppression control method for rotating electrical machine

A technology for rotating electrical machines and torque fluctuations, applied in the field of periodic disturbance suppression control, and can solve problems such as low rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

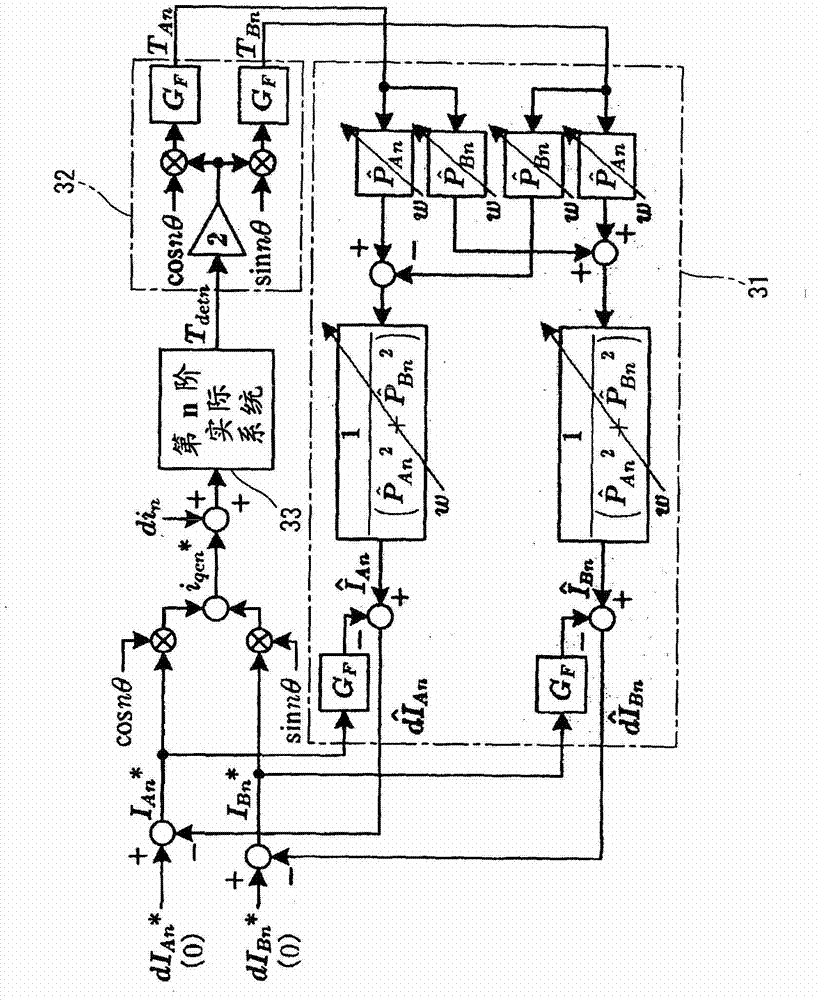

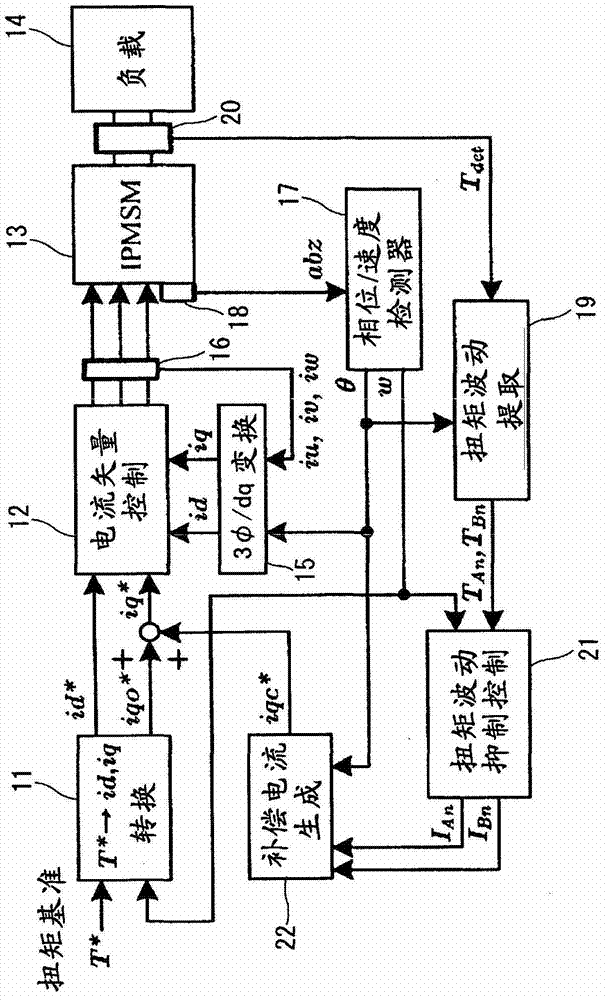

[0108] figure 1 is a computational block diagram of torque fluctuation suppression control using a periodic disturbance observer according to an embodiment of the present invention.

[0109] Torque fluctuation extraction part 32 ( image 3 The torque ripple frequency component extraction section 19) shown in An and the nth order torque ripple extraction component (sine coefficient) T Bn . Periodic Disturbance Observer 31 ( image 3 The torque fluctuation suppression control section 21 shown in ) is similar to the periodic disturbance observer proposed by Non-Patent Document 1. However, in order to adopt a structure with synchronous coordinates of torque fluctuations, the periodic disturbance observer 31 uses the one-dimensional complex The inverse property of a vector.

[0110] First, the n-th order compensation current I shown by equation (2) qcn * Expressed in complex vectors. According to Euler's formula, the conversion below is obtained.

[0111] [mathematical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com