Powder for wear-resistant anti-corrosion protection of water wall tube and preparation method

A water-cooled wall pipe and powder technology, which is applied in the coating process and coating of metal materials, can solve the problems of poor high-temperature erosion resistance and affect the corrosion resistance of cladding layers, etc., and achieve long wear and corrosion resistance life, The effect of prolonging the life of wear and corrosion resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

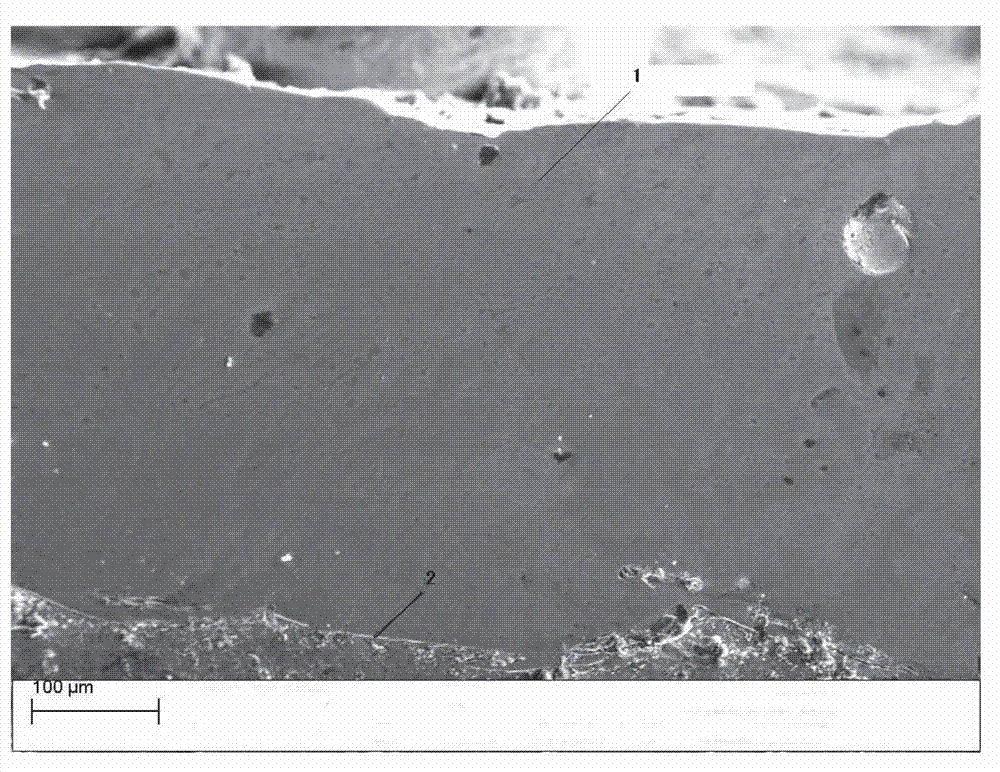

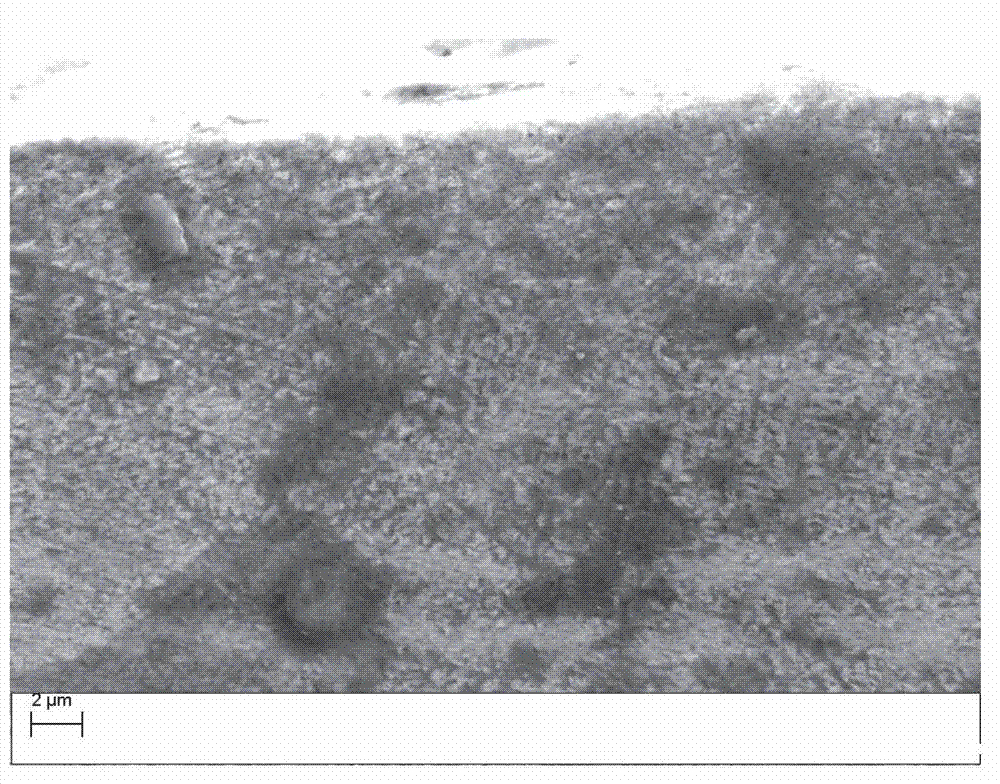

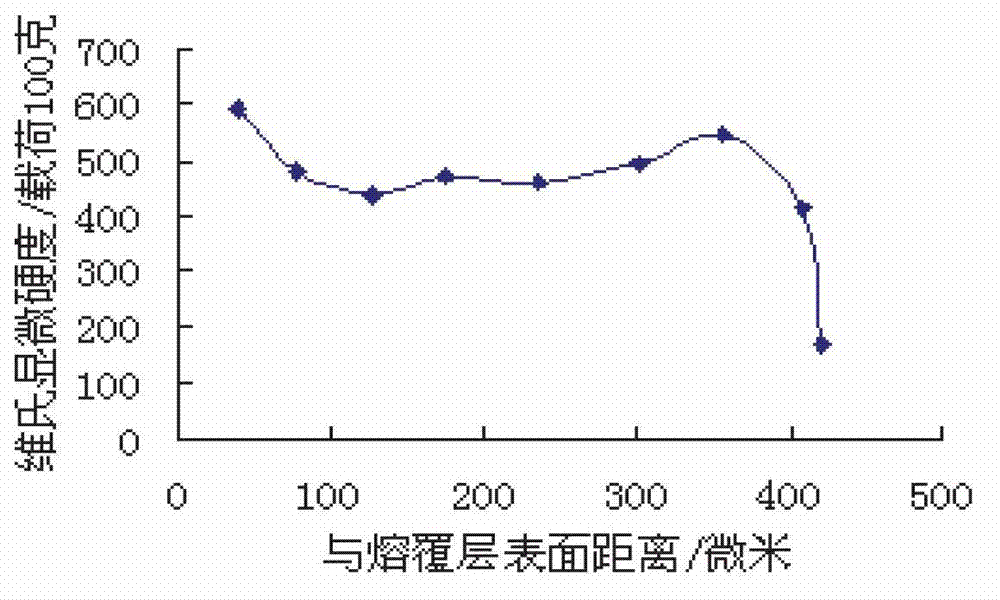

[0027] Example: Preparation of cladding layer on the heating surface of the water-cooled wall tube

[0028] 1. Preparation of powder raw materials

[0029] The weight percent scope of powder raw material is as follows:

[0030] CrB 2 Powder (particle size -140+325 mesh, purity 99.5%): 12 wt.%; C powder: 0.8wt.%; Ni-Cr-Ti-Mo-Fe-V alloy powder (particle size -140+325 mesh): Yu Amount; Among them, the composition of Ni-Cr-Ti-Mo-Fe-V alloy powder is: Cr: 25wt.%; Ti: 5wt.%; Mo: 3wt.%; Fe: 3wt.%; V: 0.8wt. %;Ni: balance.

[0031] 2. Preparation of mixed powder

[0032] (1) According to the various powder ratios described in step 1, weigh the required various powder raw materials;

[0033] (2) Put the powder raw material into a drying oven for drying, the temperature of the drying oven is 120°C, and the drying time is 4 hours;

[0034](3) Use the HS conical mixer to mix the powder raw materials to form a uniformly mixed powder, and the mixing time is 4 hours;

[0035] (4) Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com