An iron-based amorphous powder for wear-resistant and corrosion-resistant coatings and its preparation method

An iron-based amorphous and powder technology, applied in the coating, metal material coating process, etc., can solve the problems of large interface dilution rate of argon arc surfacing coating, low bonding strength, thermal deformation of the base material, etc., and achieve high Wear-resistant and corrosion-resistant characteristics, low preparation cost, long wear-resistant and corrosion-resistant life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

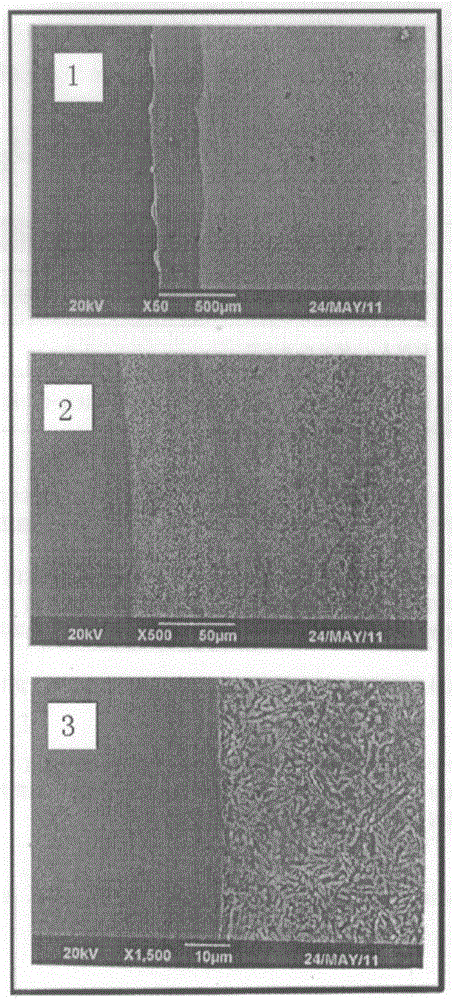

[0029] Example 1: Preparation of wear-resistant and corrosion-resistant cladding layer on the surface of oil drill pipe

[0030] 1. Preparation of mixed powder

[0031] 1. Preparation of powder raw materials

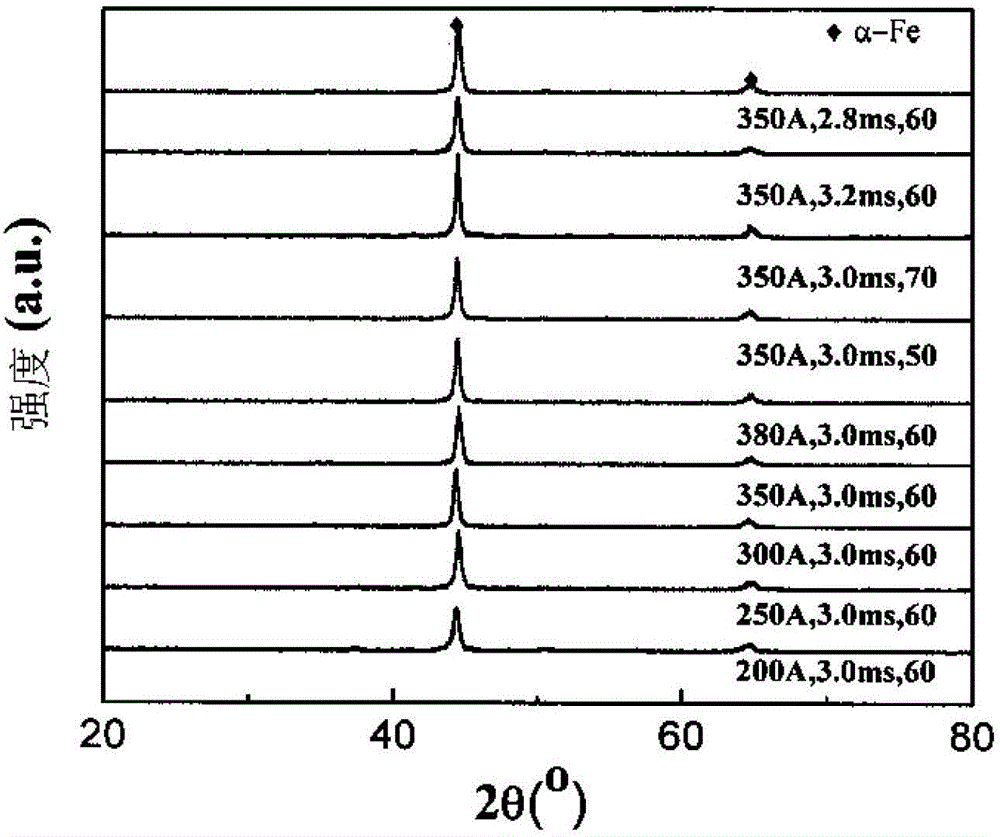

[0032] The weight percent composition of the iron-based amorphous powder is represented by the following general formula:

[0033] Fe a Cr b Ni c Si d B e Mn f C g Mo h Nb i Cu j Co k Re l (The subscript is weight percentage), wherein Re represents rare earth element Ce or Y, and the weight percentage range of the powder raw material is as follows, wherein b: 30wt.%, c: 10wt.%, d: 3.5wt.%, e: 8wt.%, f: 3wt.%, g: 3wt.%, h: 8wt.%, i: 1wt.%, Re is Ce, content l is 0.5wt.%, iron powder content a is the balance.

[0034] The mesh number of each raw material is 100-400. In order to reduce the melting point, cost and volatility, etc., some raw materials are selected as intermediate alloy powder.

[0035] 2. Preparation process of mixed powder

[0036] (1) accord...

Embodiment 2

[0046] Example 2: Preparation of iron-based amorphous cladding layer on the outer surface of the economizer tube

[0047] 1. Preparation of mixed powder

[0048] 1. Preparation of powder raw materials

[0049] The weight percent composition of the iron-based amorphous powder is represented by the following general formula:

[0050] Fe a Cr b Ni c Si d B e Mn f C g Mo h Nb i Cu j Co k Re l (the subscript is weight percent), wherein Re represents rare earth element Ce or Y, and the weight percent range of the powder raw material is as follows, wherein b: 20wt.%, c: 12wt.%, d: 2.5wt.%, e: 7wt.%, f: 2wt.%, h: 10wt.%, j: 1wt.%, k: 5wt.%, Re is Y, content l is 1wt.%, iron powder content a is the balance.

[0051] The mesh number of each raw material is 100-400. In order to reduce the melting point, cost and volatility, etc., some raw materials are selected as intermediate alloy powder.

[0052] 2. Preparation process of mixed powder

[0053] (1) according to the vari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

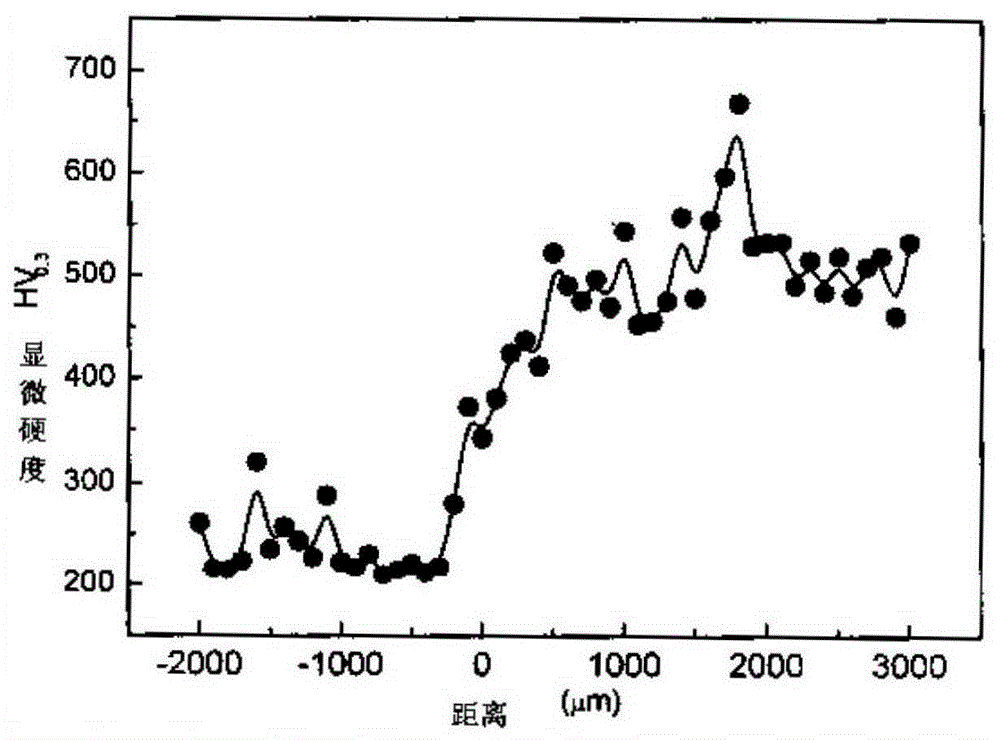

| microhardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com