Hole making method with alignment based on machine vision

A machine vision and vision technology, applied in the direction of manufacturing tools, drilling/drilling equipment, boring machine/drilling machine components, etc., can solve the problems that affect the user's visualization level and programming efficiency, so as to reduce labor intensity and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

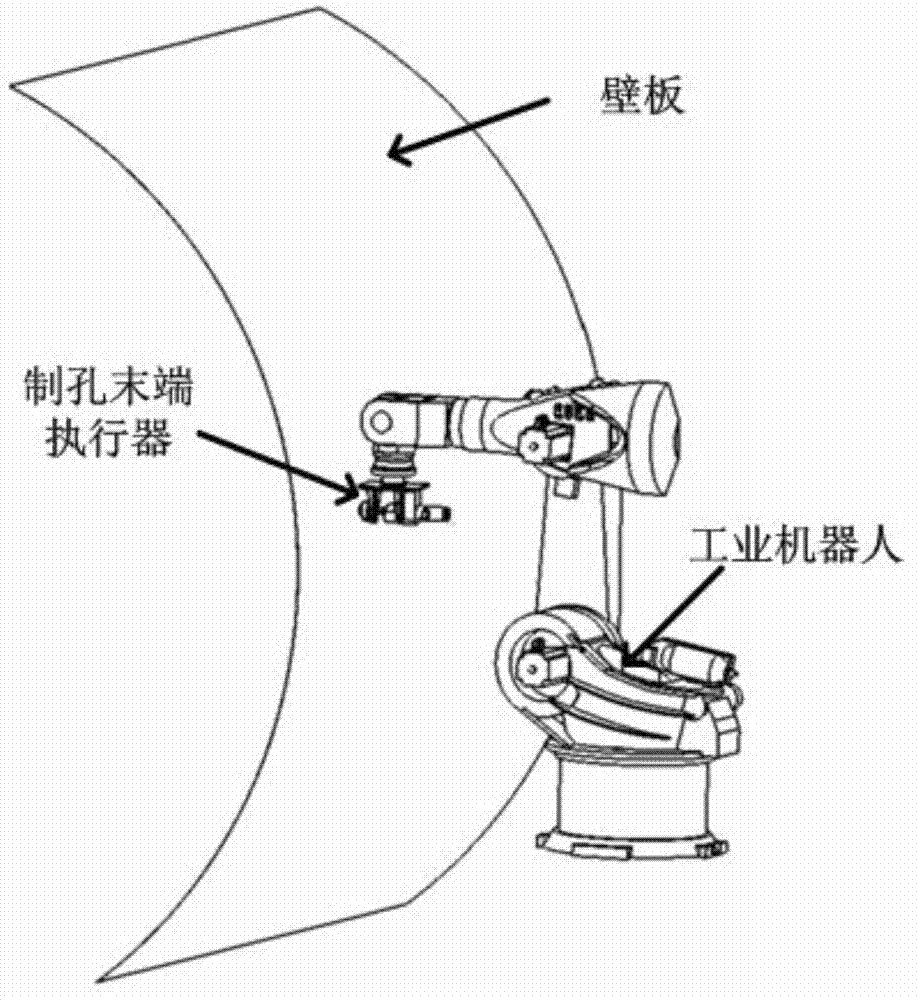

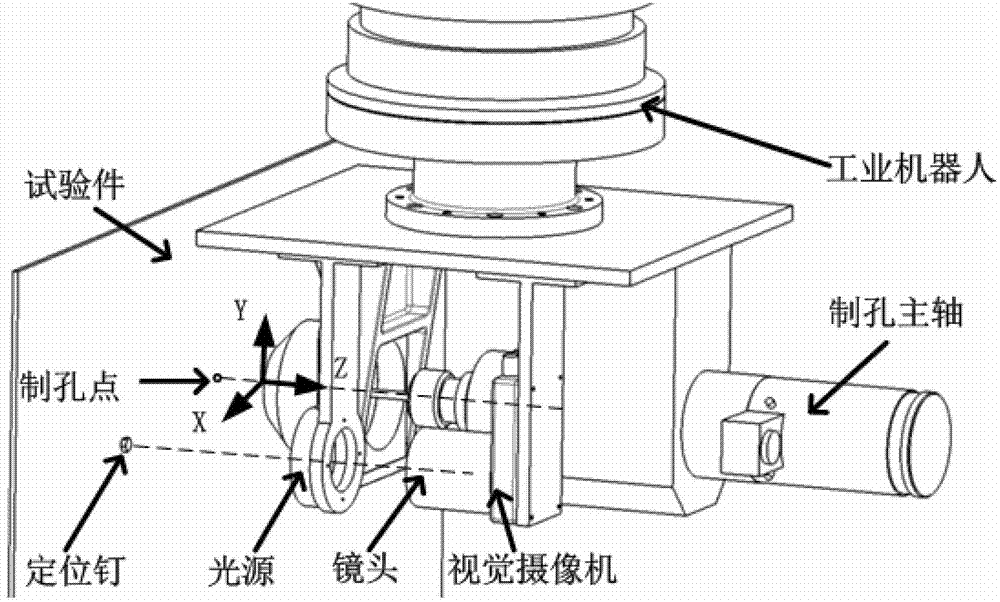

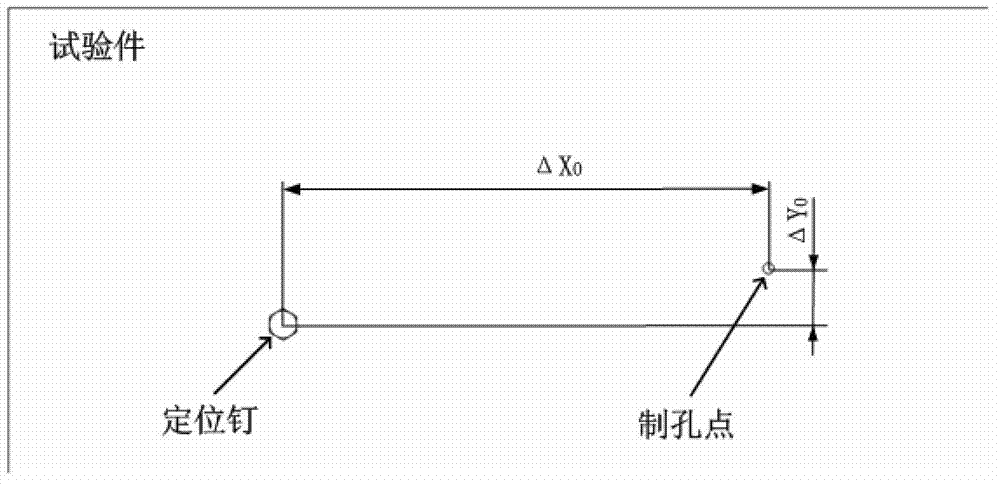

[0027] The invention is used to accurately locate the position coordinates of the positioning nails on the aircraft wall plate when the industrial robot automatically makes the hole; update the theoretical positioning nail position information in the digital model and offline program, and then provide the upper computer and the industrial robot controller with all The location information of hole making is required, which can significantly improve the accuracy of hole making location.

[0028] The invention provides a hole position alignment method based on machine vision, which is used for automatic hole making of aircraft wall panels, calibrates the position of the visual camera and the hole making spindle, and updates the theoretical positioning nails and actual positioning nails in the digital model and offline programs. The positional offset error of the positioning nail ensures the positional accuracy of the industrial robot's hole making. The closed-loop system formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com