Stopping anti-off device for penicillin bottles

An anti-off device and vial technology, which is applied in the direction of stopper fixing, etc., can solve the problems of high cost, high cost, falling off, etc., and achieve the effects of improving stoppering accuracy, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

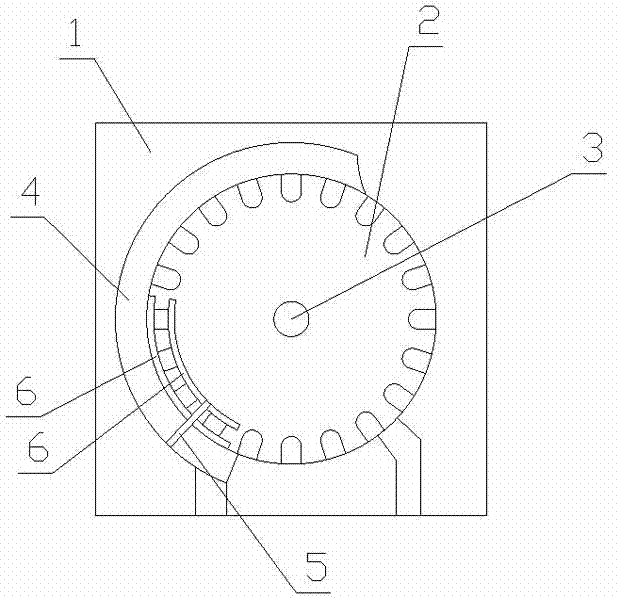

[0008] Vial stopper anti-off device of the present invention, as figure 1 As shown, it includes a workbench 1 and a disc-shaped turntable 2. There is a shaft hole in the center of the turntable 2, and a shaft 3 is installed in the shaft hole. The bottom end of the shaft 3 is connected to the center of the workbench 1. A flange 4 is provided, and a plurality of grooves are evenly arranged on the edge of the turntable 2 with the center of the turntable 2 as the center of a circle. A slideway is installed above the groove of the turntable, and the slideway is connected with the flange 4 through a connecting rod 5 .

[0009] Slideway comprises two arc-shaped guide bars 6, and an arc-shaped guide bar 6 is arranged on the circumference of the bottom of the groove of the rotating disk 2, and another arc-shaped guide bar 6 is arranged on the circumference of the top of the groove of the rotating disk 2 grooves. The distance between the curved guide strips 6 is slightly greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com