Method for preparing magnesium samarium intermediate alloy with high-intensity ultrasound

A high-energy ultrasonic and master alloy technology is applied in the field of high-energy ultrasonic preparation of magnesium-samarium master alloys, which can solve the problems of easy oxidation, removal, and high melting point, and achieve the effects of stable content, reduced component segregation, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1: First, put the pure magnesium ingot into the crucible and heat it to melt, wrap the rare earth samarium particles with a diameter of 20-100um (the purity of Sm is 99.9%) with aluminum foil, and add it to the above pure magnesium melt. The mass of rare earth samarium in the melt accounted for 40% of the total weight, and then kept at 731 °C for 31 min. Extend the ultrasonic horn into the melt for intermittent ultrasonic treatment with an ultrasonic intensity of 1.01kw / cm 2 , the ultrasonic time is 26, the application time of high-energy ultrasonic is 21 s each time, and the intermittent time is 21 s. Refining and removing impurities at 731°C, casting and sampling.

Embodiment 2

[0009] Example 2: First put the pure magnesium ingot into the crucible and heat it to melt, wrap the powdered rare earth samarium (the purity of Sm is 99.9%) with aluminum foil, add it to the above pure magnesium melt, the rare earth samarium in the alloy melt The mass accounted for 40% of the total weight, and then kept at 733 °C for 33 min. Extend the ultrasonic horn into the melt for intermittent ultrasonic treatment with an ultrasonic intensity of 1.05kw / cm 2 , the ultrasonic time was 28 min, the application time of high-energy ultrasonic was 23 s each time, and the interval time was 23 s. Refining and removing impurities at 733°C, casting and sampling.

Embodiment 3

[0010] Embodiment 3: first put the pure magnesium ingot into the crucible and heat it to melt, then wrap the powdered rare earth samarium (the purity of Sm is 99.9%) with a mass fraction of 40% in aluminum foil, and add it to the above pure magnesium melt, The mass of rare earth samarium in the alloy melt accounts for 40% of the total weight, and then it is kept at 735°C for 35 min. Extend the ultrasonic horn into the melt for intermittent ultrasonic treatment with an ultrasonic intensity of 1.1 kw / cm 2 , the ultrasonic time was 30 min, the high-energy ultrasonic was applied for 25 s each time, and the intermittent time was 25 s. Refining and removing impurities at 735°C, casting and sampling.

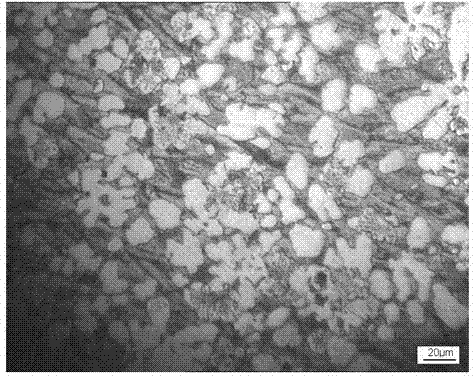

[0011] attached figure 1 This is the metallographic diagram of the microstructure of the magnesium-samarium master alloy obtained in Example 3. It can be seen from the figure that the eutectic structure of the obtained magnesium-samarium master alloy structure is very uniform and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com