Method for preparing aluminum-holmium intermediate alloy by virtue of high-energy ultrasonic

A high-energy ultrasonic and master alloy technology, which is applied in the field of high-energy ultrasonic preparation of aluminum-holmium master alloy, can solve the problems of difficult control of alloy composition, harm to human health, and large fluctuation range, and achieve stable rare earth content, convenient operation, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: First put the pure aluminum ingot into the crucible and heat it to melt, wrap the rare earth holmium particles with a diameter of 20-100um in aluminum foil, and press them into the above pure aluminum melt, wherein the purity of the rare earth holmium is 99.9%. Insulate at 765°C for 30 minutes, wherein the rare earth holmium content accounts for 10% of the total weight. Apply intermittent high-energy ultrasound at a place 10mm below the surface of the above alloy melt, with an ultrasound intensity of 0.6kw / cm 2 , the application time is 8min, the high-energy ultrasonic is applied for 30 seconds each time, and the intermittent time is 30 seconds, and then the alloy melt is lowered to 700°C for refining and impurity removal and casting.

Embodiment 2

[0015] Example 2: First put the pure aluminum ingot into the crucible and heat it to melt, wrap the rare earth holmium particles with aluminum foil, press them into the above pure aluminum melt, wherein the purity of the rare earth holmium is 99.9%, and keep it at 775°C for 40 Minutes, wherein the rare earth holmium content accounts for 10% of the total weight. Apply intermittent high-energy ultrasound at a place 15mm below the surface of the alloy melt, with an ultrasound intensity of 0.8kw / cm 2 , the application time is 12min, the high-energy ultrasonic is applied for 40 seconds each time, and the intermittent time is 40 seconds, and then the alloy melt is lowered to 710°C for refining and impurity removal and casting.

Embodiment 3

[0016] Example 3: First put the pure aluminum ingot into the crucible and heat it to melt, wrap the rare earth holmium powder with aluminum foil, press it into the above pure aluminum melt, wherein the purity of the rare earth holmium is 99.9%, and keep it at 785°C for 40 Minutes, wherein the rare earth holmium content accounts for 10% of the total weight. Apply intermittent high-energy ultrasound at a place 15mm below the surface of the alloy melt, with an ultrasound intensity of 0.8kw / cm 2 , the application time is 15 minutes, the application time of high-energy ultrasonic is 50 seconds each time, and the intermittent time is 50 seconds, and then the alloy melt is lowered to 710 ° C for refining and impurity removal and casting.

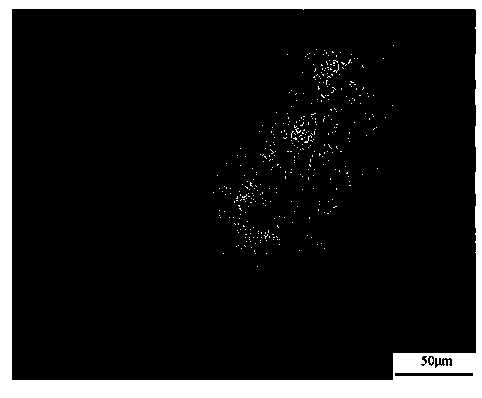

[0017] attached figure 1 It is the metallographic diagram of the eutectic structure of the aluminum holmium master alloy structure that embodiment 2 obtains, by appending figure 1 It can be seen that the distribution of the eutectic structure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com