Method for preparing magnesium-lanthanum master alloy by high-intensity ultrasound

A master alloy and high-energy ultrasonic technology, which is applied in the field of preparation of magnesium-lanthanum master alloy, can solve the problems of difficult control of alloy composition, harm to human health, and generation of toxic gas, and achieve the effects of avoiding rare earth burning loss, convenient operation, and reducing oxidation inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Implementation Example 1: First, put the pure magnesium ingot into the crucible and heat it to melt, then wrap the powdered rare earth lanthanum (the purity of La is 99.9%) with a mass fraction of 15% in aluminum foil, and add it to the above pure magnesium melt, It was then incubated at 700°C for 30 minutes. Extend the ultrasonic horn into the melt for ultrasonic treatment. Ultrasonic for 30 minutes, the ultrasonic power is 800W, refining and removing impurities at 700°C, casting and sampling.

Embodiment 2

[0011] Implementation Example 2: First put the pure magnesium ingot into the crucible and heat it to melt, then wrap the powdered rare earth lanthanum (the purity of La is 99.9%) with a mass fraction of 15% and add it to the above pure magnesium melt, It was then incubated at 710°C for 25 minutes. Extend the ultrasonic horn into the melt for ultrasonic treatment. Ultrasonic for 40 minutes, the ultrasonic power is 600W, refining and removing impurities at 710°C, casting and sampling.

Embodiment 3

[0012] Implementation example 3: first put the pure magnesium ingot into the crucible and heat it to melt, then wrap the powdered rare earth lanthanum (the purity of La is 99.9%) with a mass fraction of 15% and add it to the above pure magnesium melt, It was then incubated at 720°C for 20 minutes. Extend the ultrasonic horn into the melt for ultrasonic treatment. Ultrasonic for 45 minutes, the ultrasonic power is 400W, refining and removing impurities at 720°C, casting and sampling.

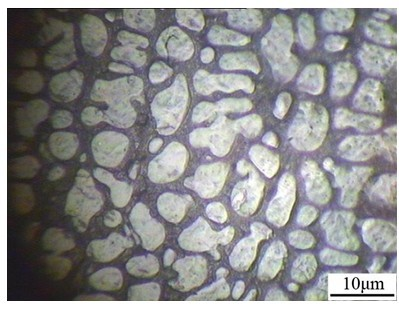

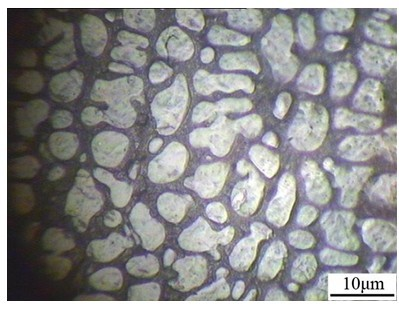

[0013] Such as figure 1 As shown, the eutectic structure of the Mg-La master alloy obtained under the conditions of Example 2 is very uniform in distribution and round in shape. When ultrasonic waves are introduced into alloy melts, there will be many nonlinear effects in the propagation of sound waves, among which the main performance is cavitation and acoustic flow effects, stirring, dispersion, impact damage and thermal effects in the mechanical effects caused by cavitation and acoustic flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com