Cotton boll stripping machine

A boll peeling machine and hulling technology, applied in the direction of separating plant fibers from seeds, etc., can solve the problems of unstable work, uncleanness, complex structure, etc., and achieve the effects of good work stability, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

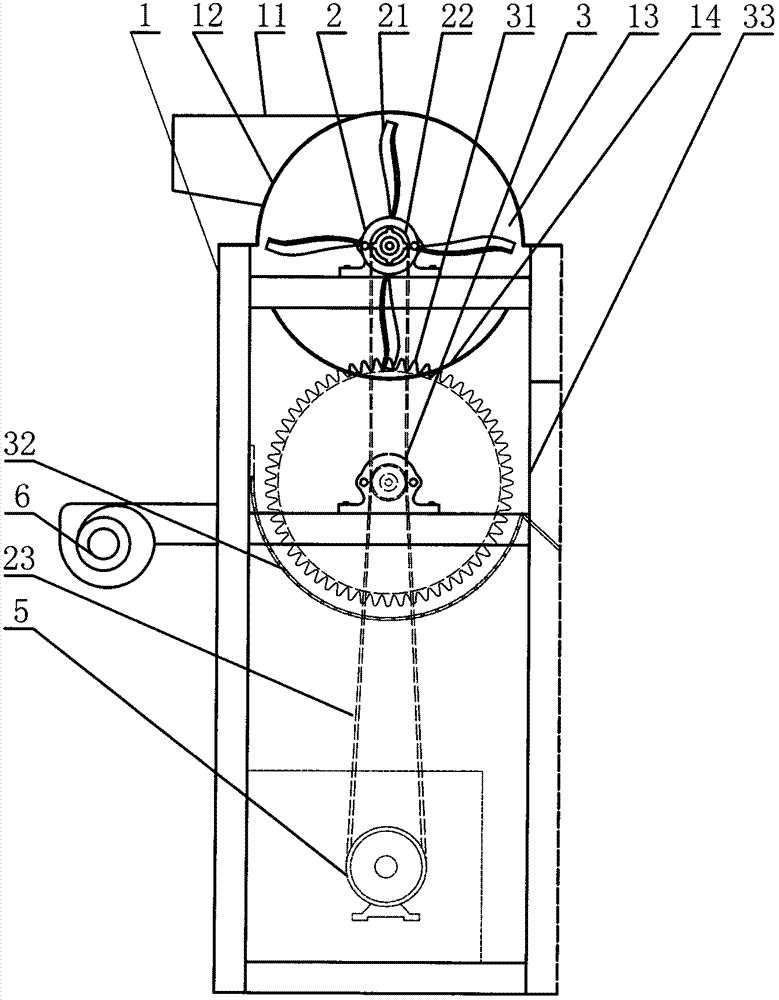

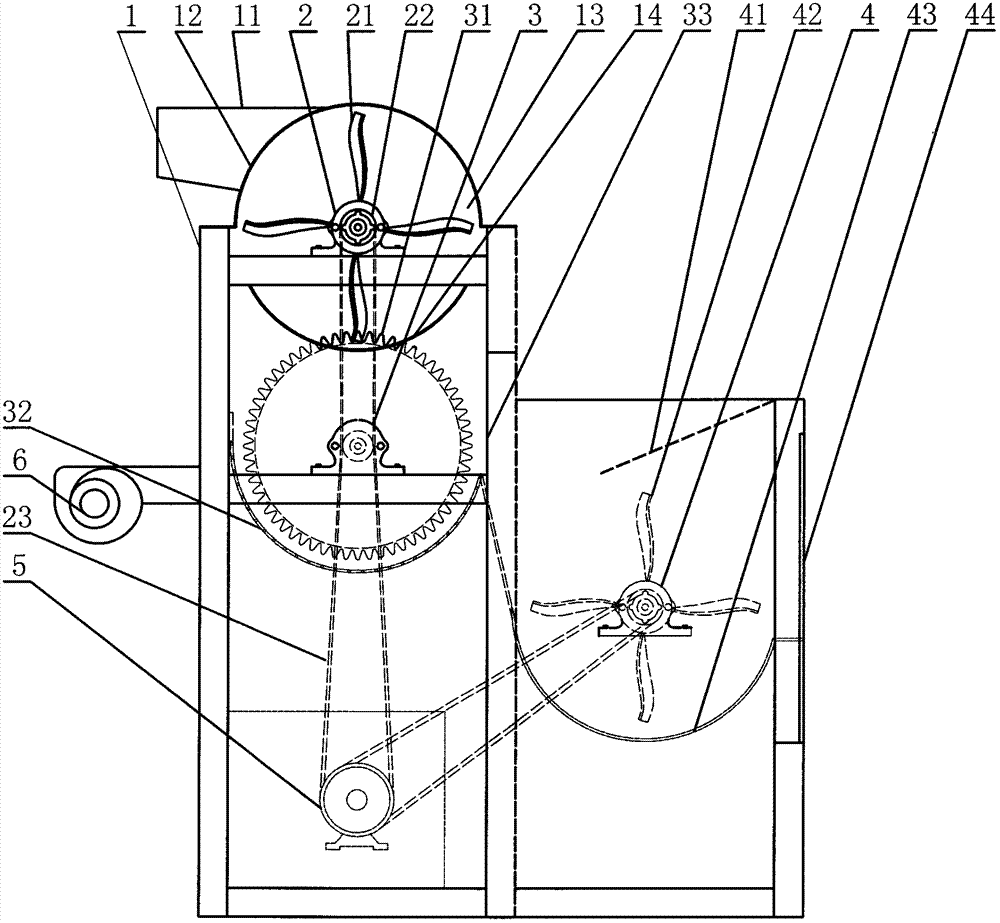

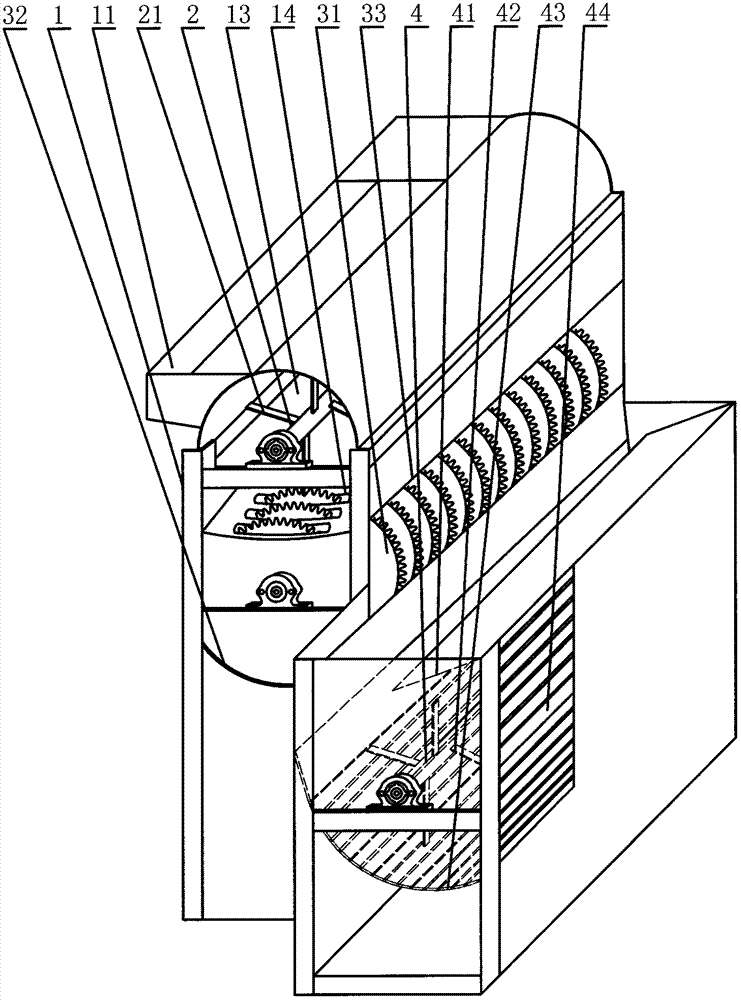

[0019] figure 1 It is a structural schematic diagram of the first embodiment of the cotton peach peeling machine of the present invention. As shown in the figure, the cotton peach peeling machine includes a frame 1, a peeling roller 2, a cotton brushing roller 3, a motor 5, a blower 6, and the like. Described frame 1 left side top is provided with feed inlet 11, and the below feed inlet 11 is provided with peeling roller 12, and peeling roller 12 is provided with peeling roller 2, and axially is provided with on the peeling roller 2. A number of staggered strip strips 21, one end of the peeling roller 12 is provided with a shell outlet 13, the bottom of the peeling roller 12 is provided with a plurality of slots 14, and the bottom of the peeling roller 12 is provided with a cotton brushing roller 3 , the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap