Special MC (Methyl Cellulose) nylon wheel for combined oilfield

A nylon wheel and combined technology, which is applied in the field of nylon products, can solve the problems of harsh working environment, affecting transmission accuracy and service life, etc., and achieves the effects of easy manufacturing, overcoming adverse effects, and reducing failure rate and replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

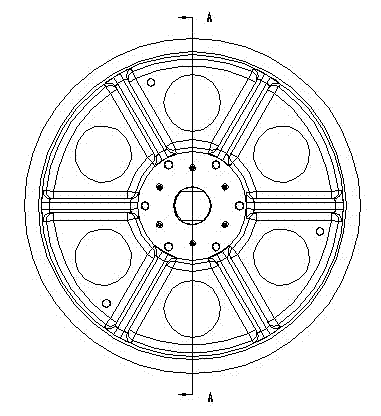

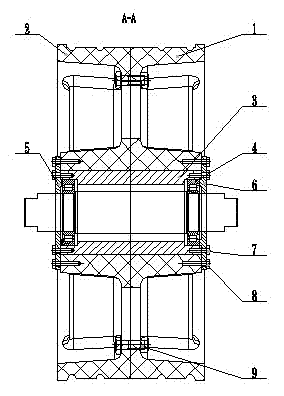

[0012] The MC nylon wheel bodies 1 and 2 made of MC nylon are connected with two (or more) steel bushings 3 concentrically arranged on the MC nylon wheel bodies. The MC nylon wheel bodies 1 and 2 are connected and fastened by bolts 9 to ensure synchronous movement of all parts. The inner walls of both ends of the rigid bushing 3 are respectively provided with annular grooves as bearing positions, and the bearing 4 is installed on the wheel shaft and supported in two annular grooves on the inner wall of the rigid bushing 3 . The two ends of the MC nylon wheel are provided with locking dust-proof end caps 5 and 6 covering the steel bushing and bearing, and the locking dust-proof end caps are respectively connected and fixed with the steel bushing and the MC nylon wheel body through bolts 7 and 8. The bolts connecting the fixed and locked dust-proof end cap and the MC nylon wheel body and the bolts connecting the fixed and locked dust-proof end cap and the steel bushing are evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com