A valve upper structure

A head and valve body technology, used in lift valves, valve devices, engine components, etc., can solve the problems of cumbersome manufacturing and installation of gaskets, and the sealing ring cannot meet the requirements of durability and tightness, so as to avoid bending effects and simplify manufacturing. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

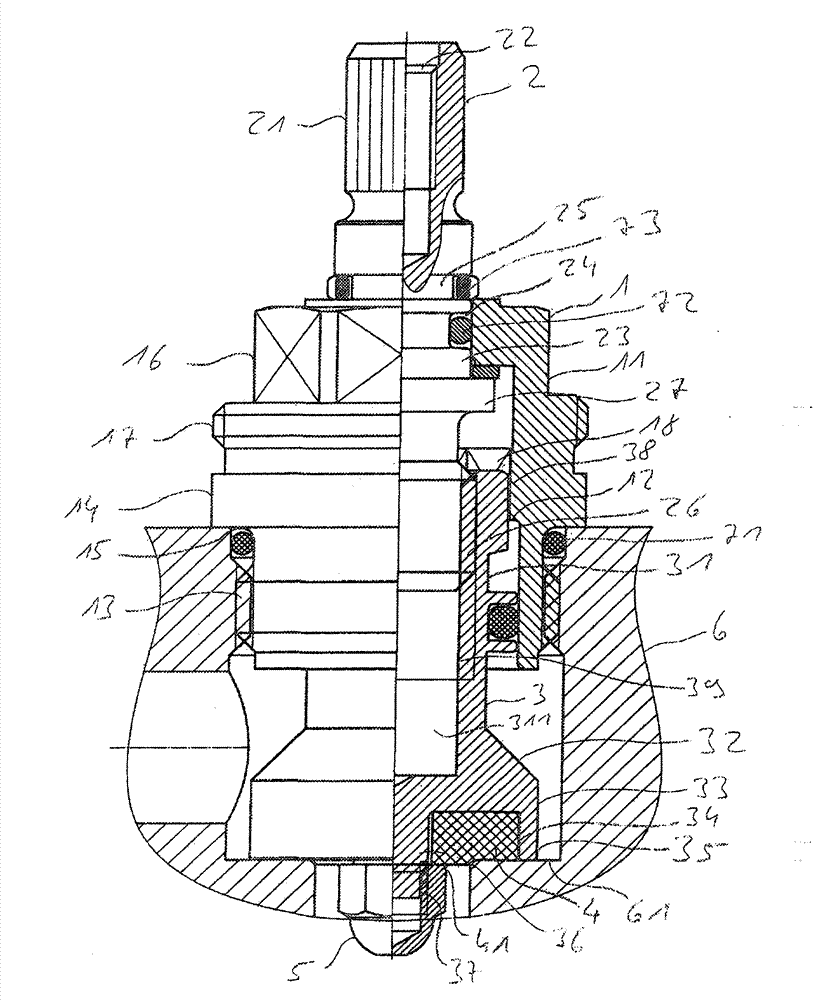

[0013] The valve superstructure chosen as embodiment has a head 1 which is penetrated in the middle by a mandrel 2 in which the mandrel passes radially. The valve body 3 is actuated via the spindle 2 and is in contact with the valve seat 61 of the housing 6 . The valve body 3 has a substantially cylindrical valve plunger 33 which carries a sealing gasket 4 which is surrounded by a peripheral edge 35 of a groove 34 which houses the sealing gasket 4, wherein the sealing gasket 4 and the groove The surrounding edge 35 of 34 is in contact with the valve seat 61 of the housing 6 .

[0014] The head 1 consists of a symmetrical hollow body which is open at both end faces. The head has a sleeve-like part 11 on its side facing the housing 6 . A stopper 12 for contacting the valve body 3 is formed on the inner periphery of the component 11 . The head 1 is provided with a connecting thread 13 on the outside of one end facing the housing 6 . The head 1 can be screwed into the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com