Pilot valve with dual-function of mechanical and electric control for unloading valve for pump

An electromagnetic pilot valve and pilot valve technology, applied in the field of pilot valves, can solve the problems of occupying a large space, inconvenient maintenance, and difficult manufacturing, and achieve the effects of reducing the overall size, facilitating maintenance, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

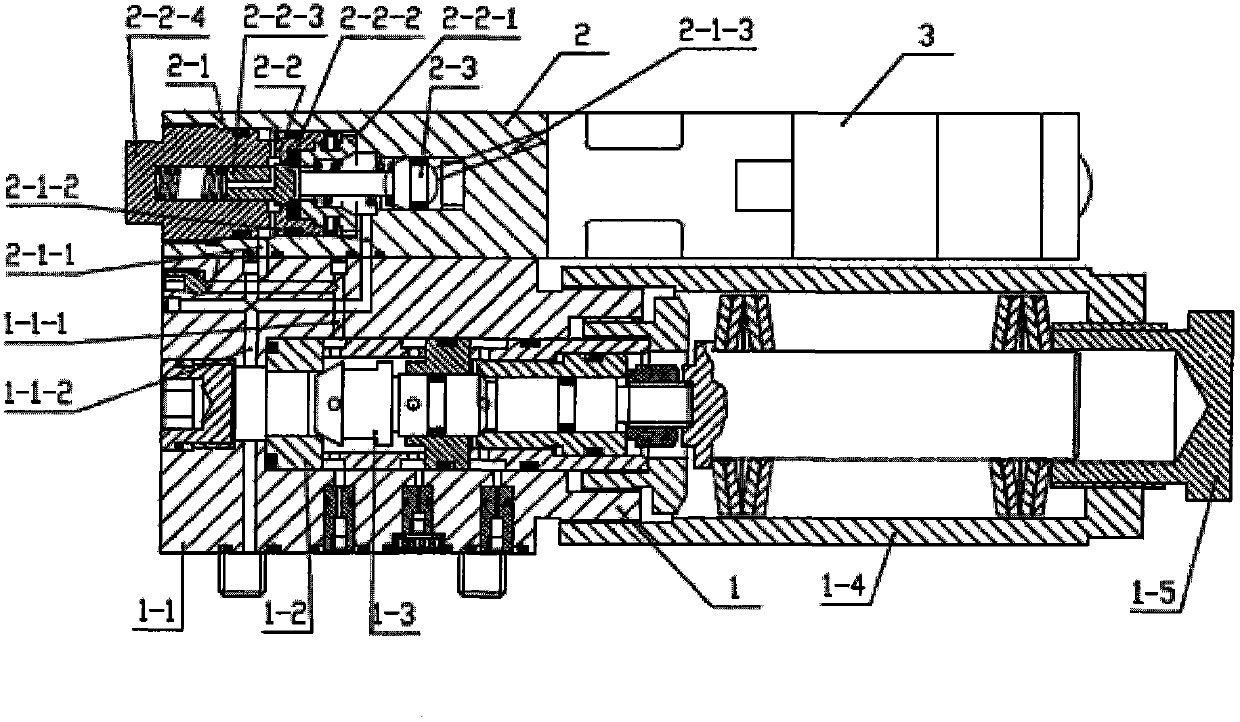

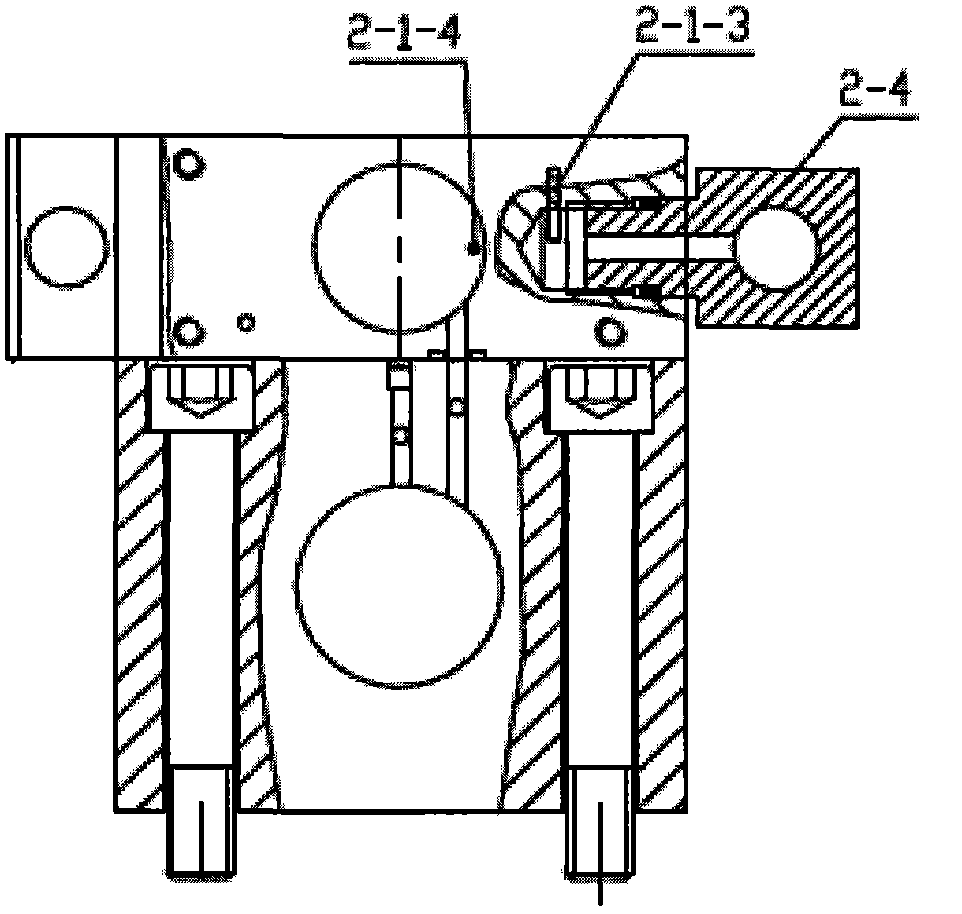

[0039] As shown in the accompanying drawings, the present invention includes a mechanical pilot valve 1, an auxiliary valve 2 functioning as an electronically controlled bypass switching valve, and an electromagnetic pilot valve 3. The mechanical pilot valve 1 includes a valve body 1-1 and a valve seat 1-2. , spool 1-3, spring sleeve 1-4 and pressure regulating screw 1-5, the first liquid channel 1-1-1 of the valve body communicated with the useful process hole is processed on the valve body 1-1 and the process The hole communicates with the second liquid channel 1-1-2 of the valve body. On the back of the mechanical pilot valve 1, the auxiliary valve 2, which acts as an electronically controlled bypass switch valve, is connected with screws. The auxiliary valve 2 includes the auxiliary valve body 2-1 , Cartridge spool 2-2 and auxiliary valve ejector rod 2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com