Construction method of universal LED bulb, and clamp ring lens type LED bulb

A technology of LED light bulbs and construction methods, which are applied in the parts of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of inconvenient use, small batches, high maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

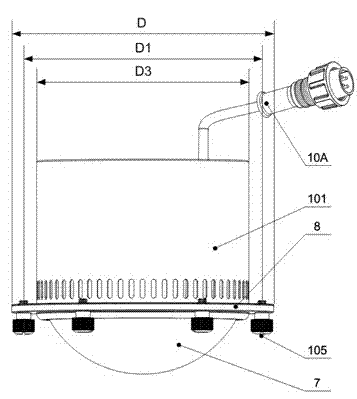

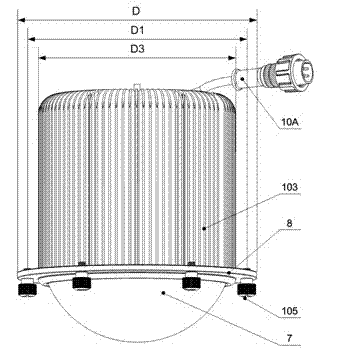

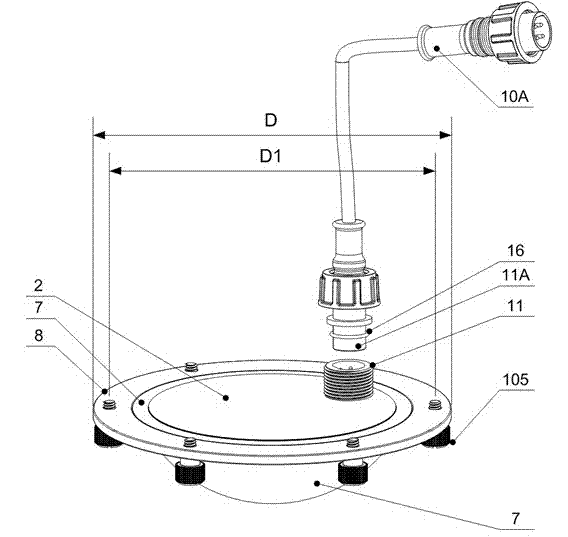

[0052] Example. The construction method of a general-purpose LED light bulb uses the lens retaining ring as the supporting body of the light bulb to support the core component of the LED light bulb optical mechanism, and the light distribution optical lens is used as an auxiliary support structure, and the light distribution optical lens is also used as the core component of the LED light mechanism. The installation base, or also cooperate with the inner snap ring as the installation base of the LED light bulb radiator; the lens snap ring is provided with a mounting flange for the installation of the light bulb; Group, inner retaining ring and light distribution optical lens, wherein the optical mechanical module is provided with an inner cover, and the heat conduction bracket is provided with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com