Device and method for measuring stress of coal particle in concentrated phase gas-solid fluidized bed

The technology of a measuring device and a measuring method is applied in the direction of measuring device, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., which can solve the problems of low measurement accuracy and reliability, and achieve the avoidance of force receiving information error, convenient control, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

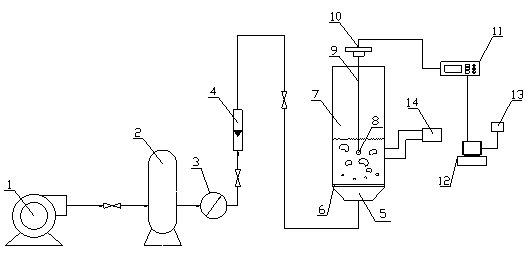

[0016] Embodiment 1: The force measurement of coal particles in the dense phase gas-solid fluidized bed of the present invention includes a force measuring device and a force measuring method.

[0017] The force measuring device, the air distribution chamber 5 and the air flow distribution plate 6 are arranged at the lower part of the gas-solid fluidized bed 7, the bottom of the gas-solid fluidized bed is connected with the rotameter 4, the wind pressure control device 3, the wind bag 2 and the fan 1 Sequentially connected, a dynamic differential pressure measuring device 14 is connected to the side of the gas-solid fluidized bed; there are coal particles in the gas-solid fluidized bed, and one end of the flexible rope 9 is closely connected with the coal particles 8; the other end of the flexible rope 9 is connected to the The high-precision contact tensioner 10, signal converter 11, data acquisition and output device 12, and data signal display 13 are sequentially connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com