Shadow-eliminating and anti-reflection electric conduction film coating layer

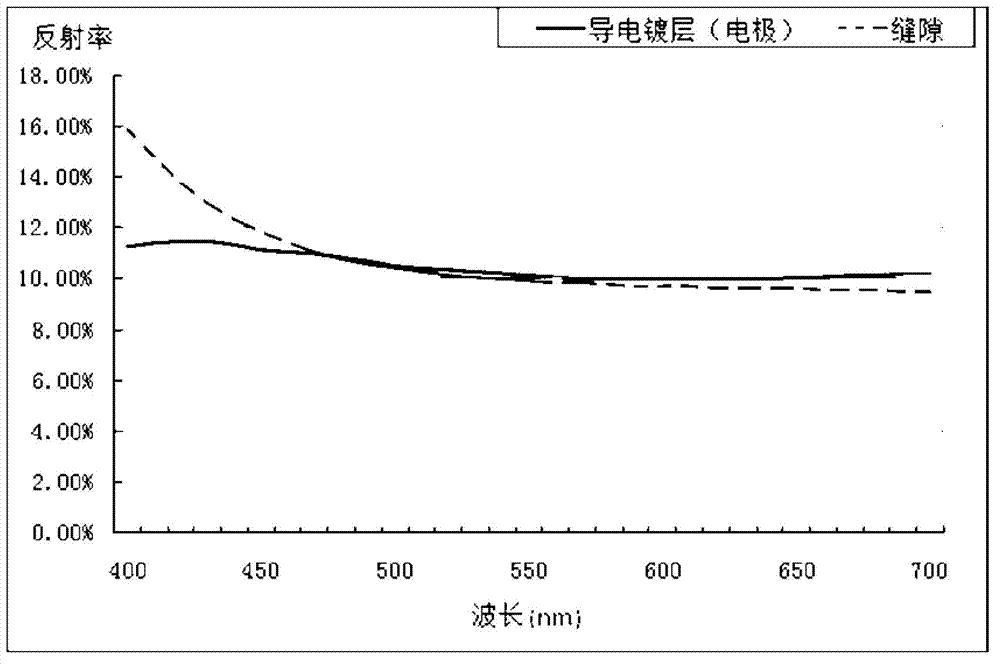

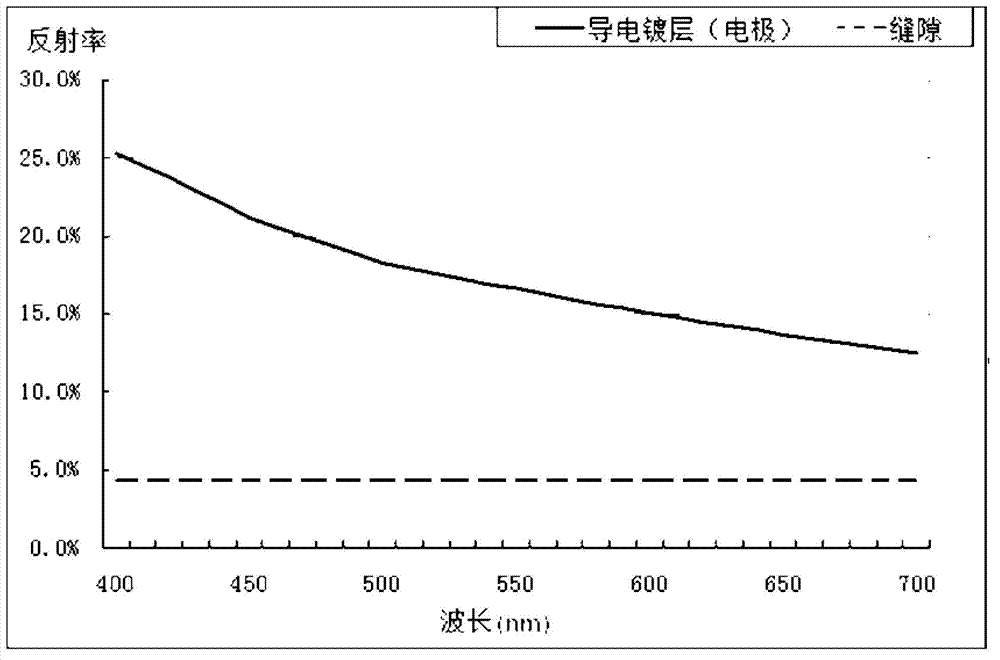

A technology of erasing anti-reflection and coating layer, which is applied to the conductive layer on the insulating carrier, electrical digital data processing, and the input/output process of data processing, etc. Can not see clearly and other problems, to achieve the effect of eliminating the shadow of the electrode gap and increasing the visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

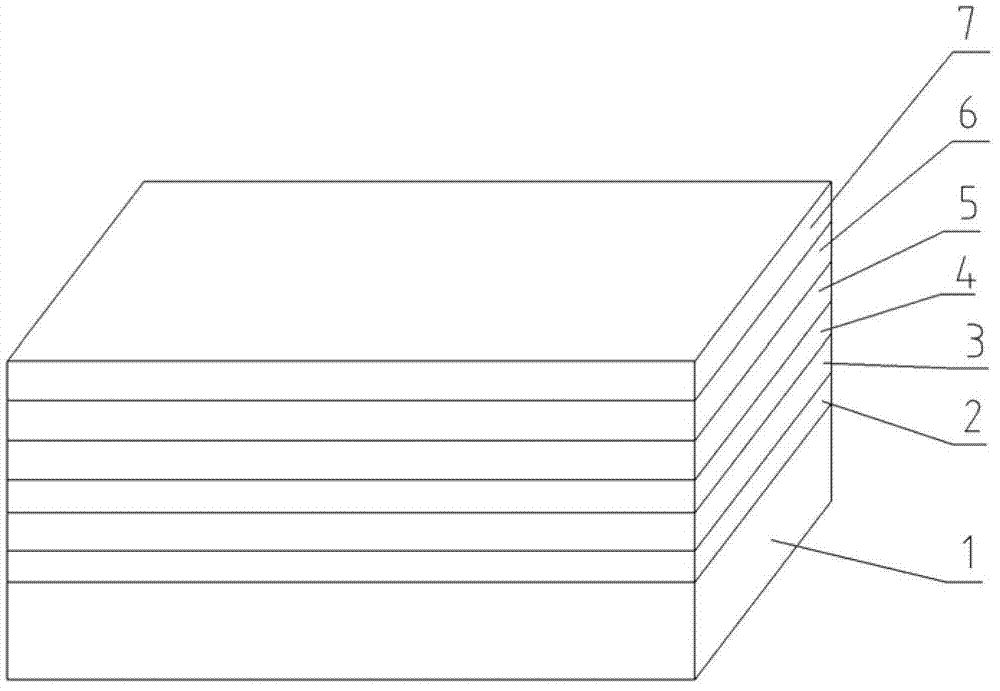

[0030] Example: such as figure 1 Show,

[0031] A six -layer composite anti -shadow -coated coating layer that can be applied to ordinary glass or transparent plastic 1 on ordinary glass or transparent plastic 1, which can be coated.The upward is: first SIO2 layer 2; first TIO2 or NB2O5 layer 3; second SIO2 layer 4; second TIO2 or NB2O5 layer 5; third SIO2 layer 6; ITO or AZO layer 7.

[0032] The thickness of the first SIO2 layer 2 is not limited; the thickness of the first TIO2 or NB2O5 layer 3 is 2-50nm; the thickness of the second SIO2 layer 4 is 10-80nm; the thickness of the second TIO2 or NB2O5 layer 5 is 2-50nm; the thickness of the third SIO 2 layer 6 is 20-80nm; the thickness of ITO or AZO layer 7 is 10-150nm.

[0033] Production process: Each coating is completed in the vacuum chamber with sputtering plating method.

[0034] Ordinary glass or transparent plastic → cleaning → vacuum coating first layer (silicon SiO2 coating) → vacuum coating second layer (titanium oxide T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com