Improved catalytic soot filter

A filter and soot technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of system volume increase limitation, cost increase, and the need for reducing agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

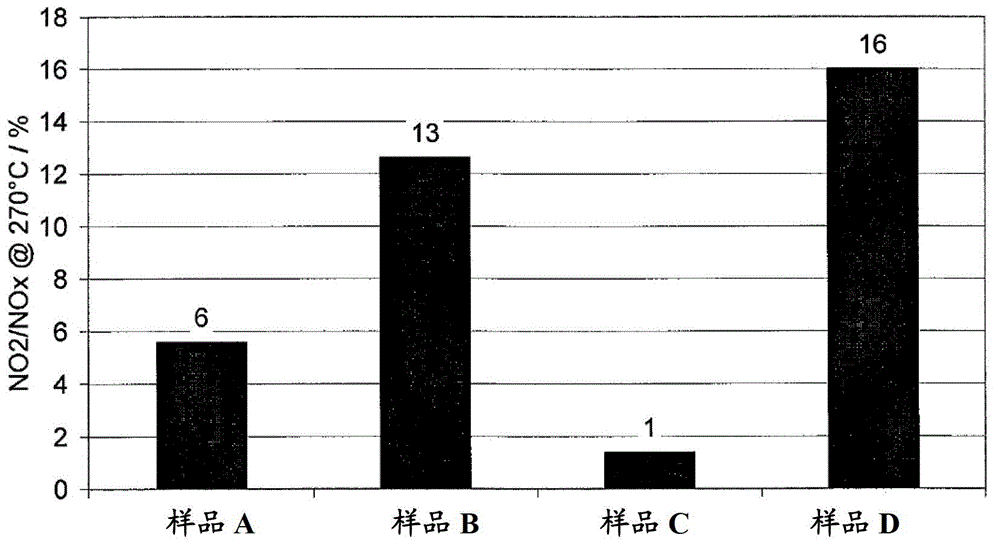

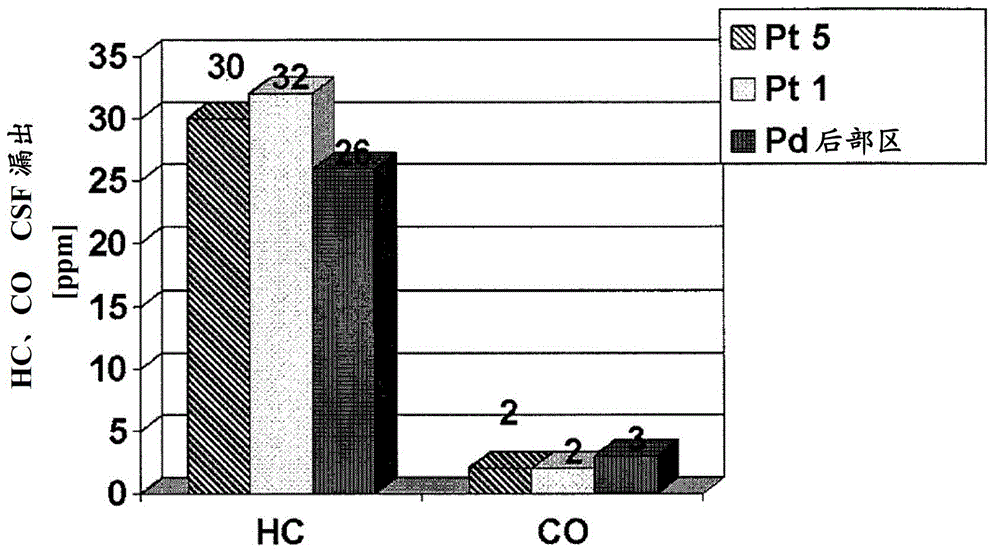

Examples

Embodiment

[0102] 1. Catalyst preparation

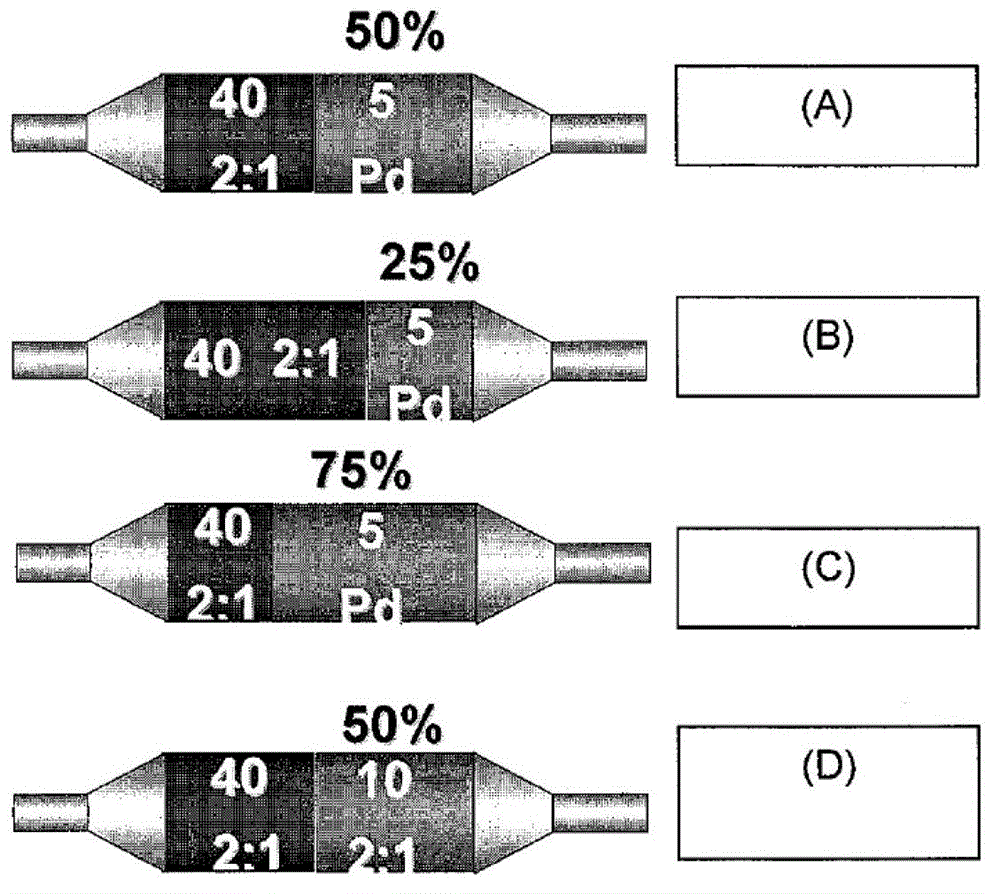

[0103] 1.1 Zoned Catalytic Soot Filter with Pd-Rear Outlet Coating - 50% Length (Sample A)

[0104] For inlet coating, use to provide 13g / ft 3 The final dry Pd content of palladium nitrate aqueous impregnated 0.25g / in 3 The gamma-alumina is then impregnated with a platinum solution of a Pt complex in which platinum is stabilized as an ammine to provide 27 g / ft 3 of dry Pt content. The resulting powder was dispersed in water. The resulting slurry was then used to coat a cordierite filter substrate from the inlet side of the filter to 50% of the full length of the filter. After drying at 110°C in air and calcination in air at 450°C, the amount of washcoat on 50% of the inlet to the filter substrate was approximately 0.27g / in 3 .

[0105] For outlet coating, use to provide 5g / ft 3 The final dry Pd content of palladium nitrate aqueous impregnated 0.25g / in 3 gamma-alumina. The resulting powder was dispersed in water. The resulting slurry w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com