Welded gearshift linkage

A shift lever and shift fork technology, which is applied in the field of shift levers, can solve problems such as the weight of shift tubes, and achieve the effects of reducing processing time, saving costs, and saving parts and working steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

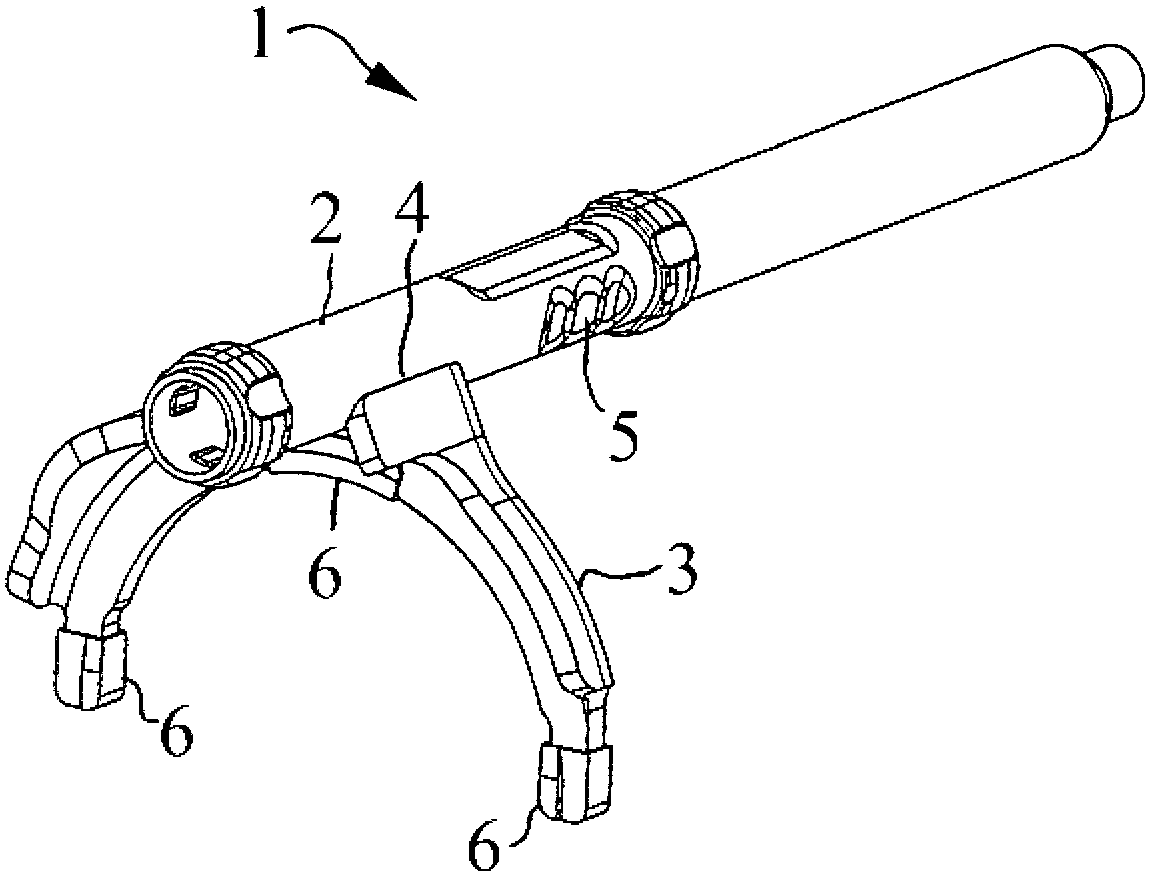

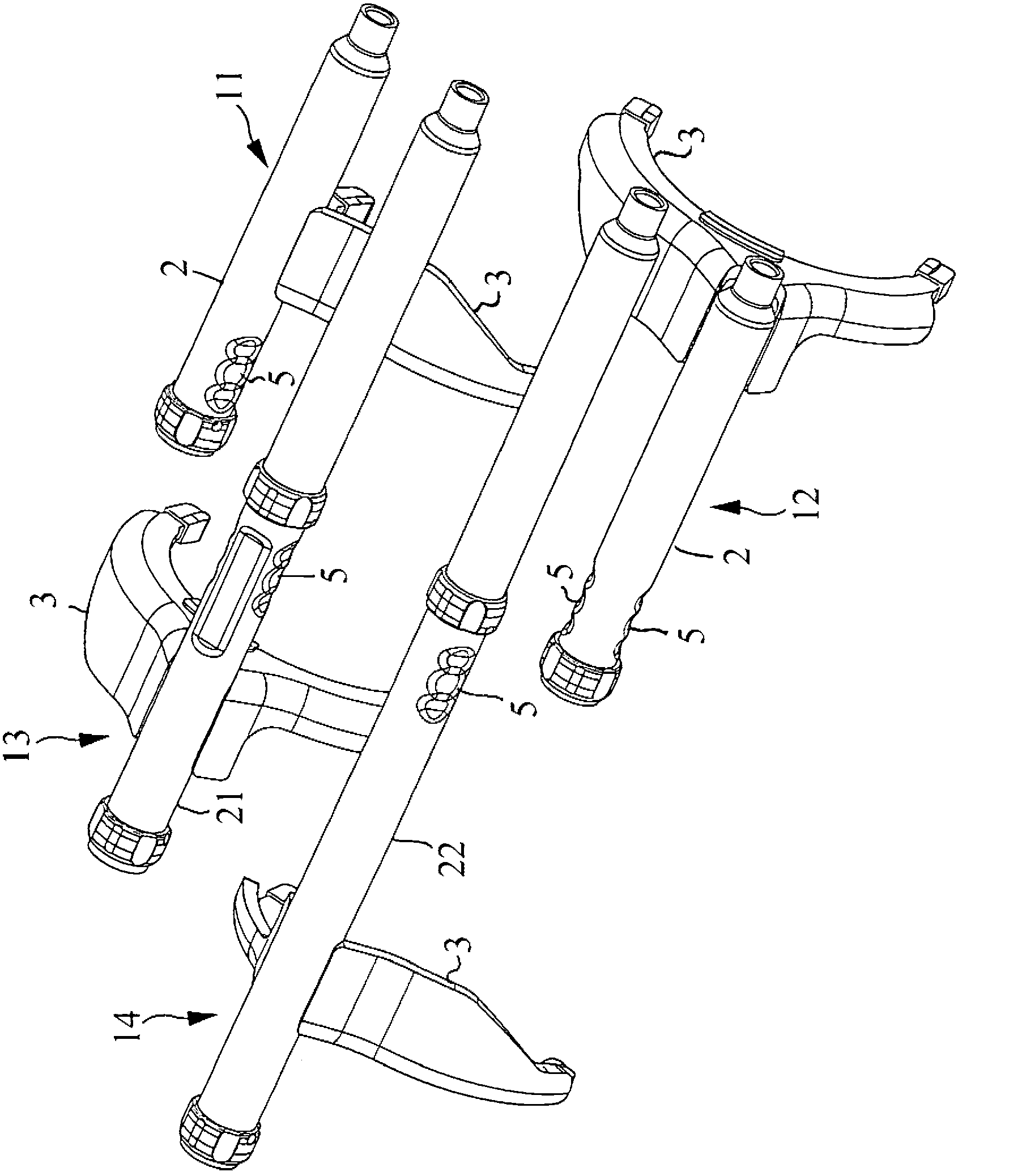

[0023] figure 1 A selector lever 1 according to the invention is shown in , which comprises a transmission tube 2 and a selector fork 3 . The shift fork 3 passes through two laser welded seams 4 (in figure 1 Only one weld 4) is shown in the figure to connect with the transmission tube 2.

[0024] The transmission tube 2 also has a detent contour 5 which is machined into the transmission tube 2 by rotary forging. The wall thickness of the transmission tube 2 can be limited to 1.5 mm by machining the detent contour 5 by rotary forging. With the directly welded connection of the selector fork 3 to the transmission tube 2 , a considerable weight saving is thereby achieved compared with conventional transmission tubes. It should also be pointed out that a plastic pad 6 is provided on the selector fork 3 and is intended to rest against other transmission components.

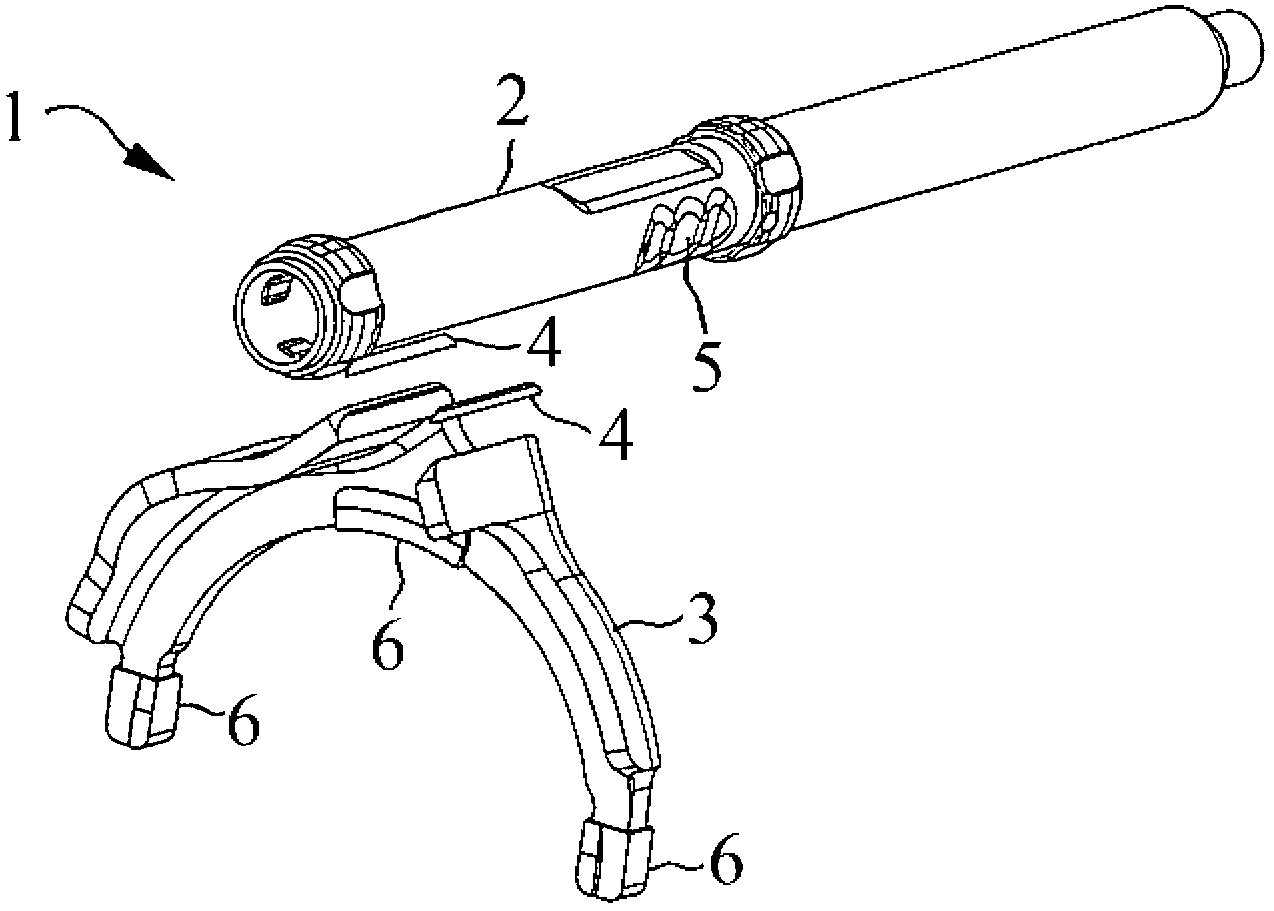

[0025] exist figure 2 shown again in a perspective, schematic exploded view figure 1 Shown is the selector le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com