Glass composition for semiconductor junction protection, production method for semiconductor device, and semiconductor device

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., to achieve the effect of high withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0059] Embodiment 1 is an embodiment related to the glass composition for semiconductor junction protection.

[0060] The glass composition for protecting a semiconductor junction according to Embodiment 1, containing at least SiO 2 、Al 2 o 3 , ZnO, CaO, 3mol% to 10mol% of B 2 o 3 , and substantially does not contain Pb, P, As, Sb, Li, Na, K.

[0061] Specifically, SiO 2 The content of Al is in the range of 32mol%~48mol% (such as 40mol%), Al 2 o 3 The content of ZnO is in the range of 9mol% to 13mol% (such as 11mol%), the content of ZnO is in the range of 18mol% to 28mol% (such as 23mol%), and the content of CaO is in the range of 15mol% to 23mol%. (eg 19mol%), B 2 o 3 The content of the compound is in the range of 3 mol% to 10 mol% (for example, 7 mol%).

[0062] As can be seen from the embodiments described later, the glass composition for protecting a semiconductor junction according to Embodiment 1 uses a glass material that does not contain lead, and can produce...

Embodiment approach 2

[0070] Embodiment 2 is an embodiment related to a manufacturing method of a semiconductor device.

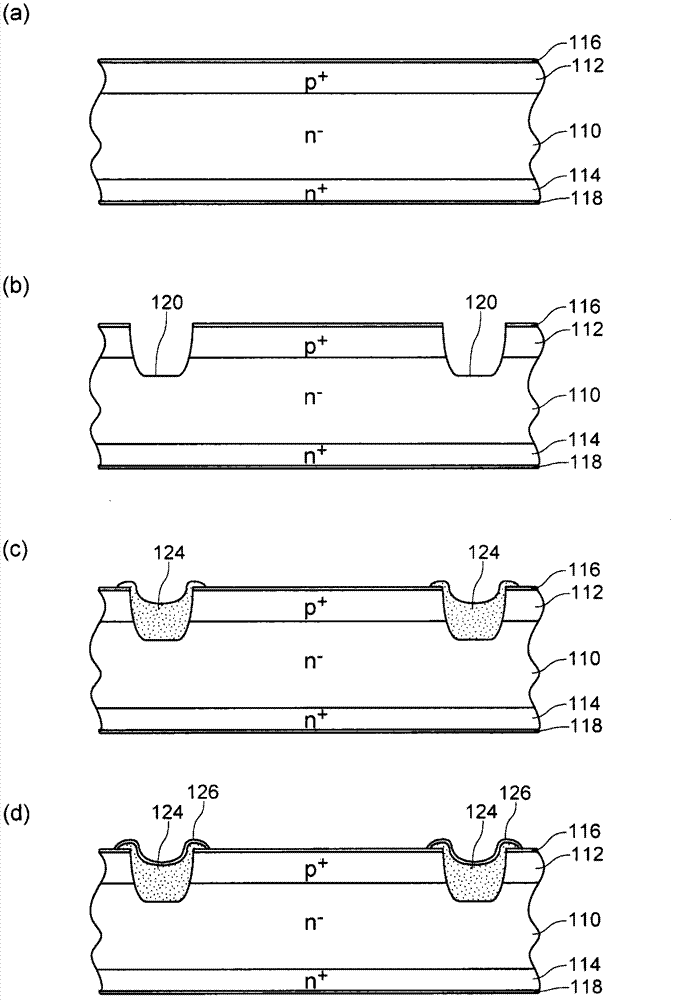

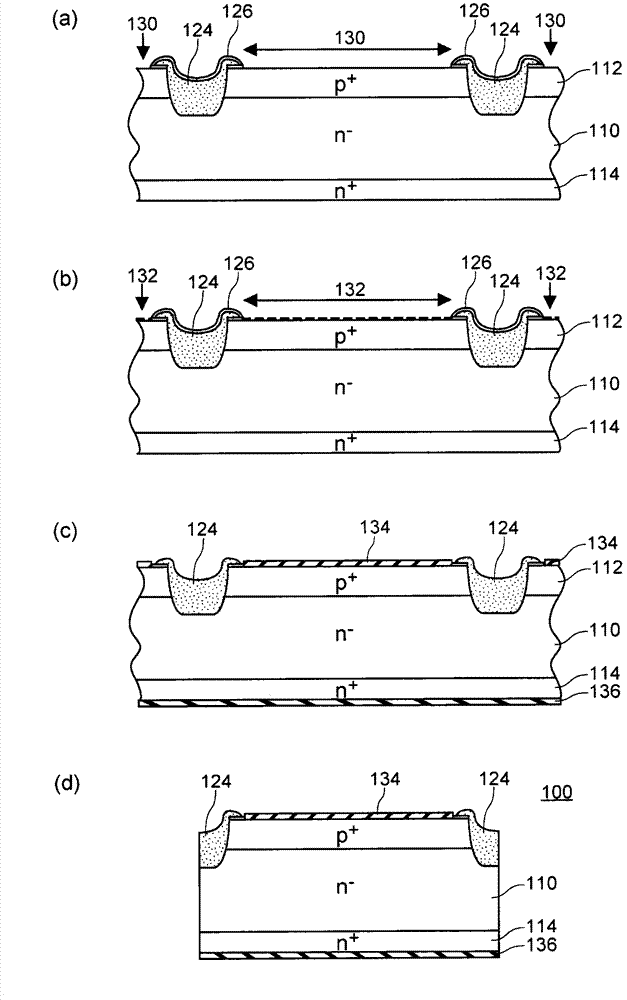

[0071] The method of manufacturing a semiconductor device according to Embodiment 2 is the manufacture of a semiconductor device including, in order, a first step of preparing a semiconductor element having a pn junction exposed portion where the pn junction is exposed, and a second step of forming a glass layer covering the pn junction exposed portion. method. In addition, in the second step, at least SiO is used 2 、Al 2 o 3 , ZnO, CaO, 3mol% to 10mol% of B 2 o 3 , and substantially free of Pb, P, As, Sb, Li, Na, and K for protecting a semiconductor junction (the glass composition for protecting a semiconductor junction according to the first embodiment) forms a glass layer. The first step includes the step of preparing a semiconductor base having a pn junction parallel to the main surface, and forming a groove in the depth of the pn junction from the surface on one side o...

Embodiment approach 3

[0092] Embodiment 3 is an embodiment related to a manufacturing method of a semiconductor device.

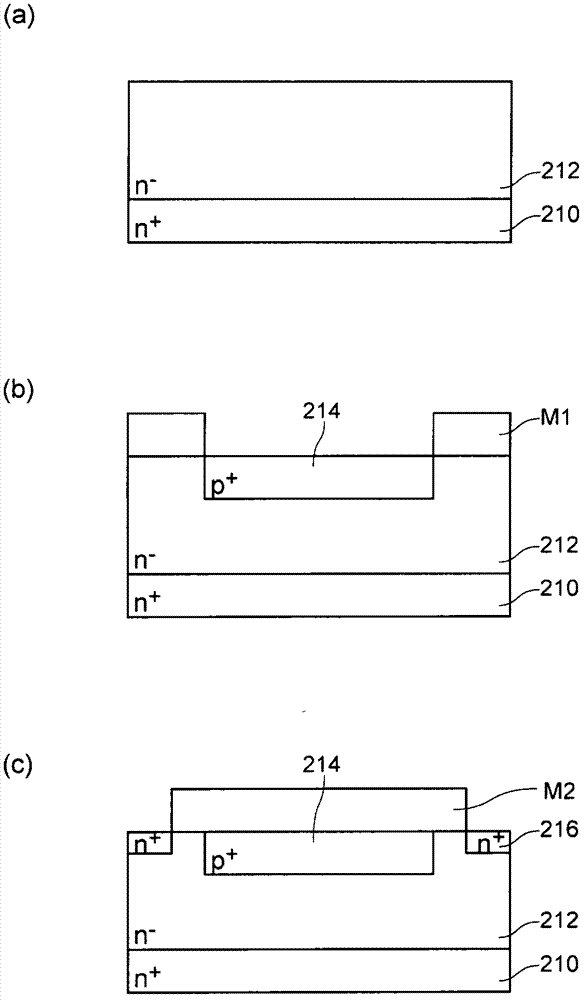

[0093] The method of manufacturing a semiconductor device according to Embodiment 3, similarly to the method of manufacturing a semiconductor device according to Embodiment 2, sequentially includes a first step of preparing a semiconductor element having a pn junction exposed portion where the pn junction is exposed, and forming a step covering the pn junction exposed portion. The second process of the glass layer. Furthermore, in the second step, using at least SiO 2 、Al 2 o 3 , ZnO, CaO, 3mol% to 10mol% of B 2 o 3 , and substantially free of Pb, P, As, Sb, Li, Na, and K for protecting a semiconductor junction (the glass composition for protecting a semiconductor junction according to the first embodiment) forms the glass layer. However, unlike the semiconductor device manufacturing method of Embodiment 2, the first step includes forming a pn junction exposed portion on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com