Integral upward flow water treatment device

An integrated technology for flow water treatment, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of low degree of automation, poor filtration water output, short filtration cycle, etc., and achieve long backwash cycle and head loss. Small, the effect of reducing the processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

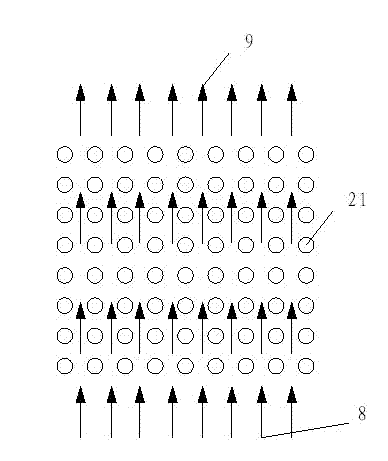

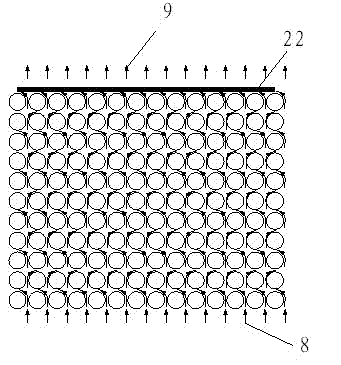

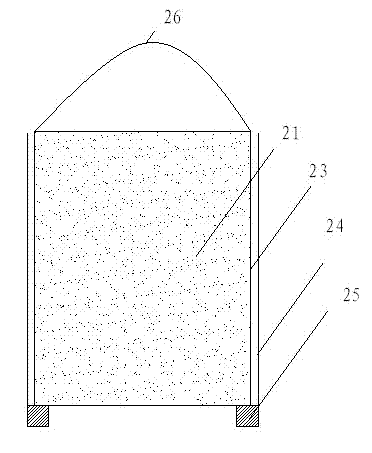

[0040] Below in conjunction with the accompanying drawings, the implementation of the present invention will be further described. The integrated upward flow water treatment device includes an inclined tube sedimentation area 1, a filter area 2 and a water outlet area 5. The inclined tube sedimentation area 1 is arranged at the lower end of the filter area 2, and in the filter area The upper end of 2 is provided with a water outlet area 5, and the lower end of the inclined pipe sedimentation area 1 is provided with a sedimentation mud discharge area 4, and a device inlet pipe 6 is arranged in the sedimentation mud discharge area 4, and the water outlet end of the device inlet pipe 6 corresponds to the inclined pipe sedimentation area The inclined pipe water inlet 111 of 1; the filter material 21 is set in the filter area 2; the filter water distribution area 3 is also set between the inclined tube sedimentation area 1 and the filter area 2, and the filter water distribution area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com