Printing ink stirrer for offset lithography

A technology of lithographic offset printing and mixer, which is applied in the direction of mixer accessories, mixers, dissolution, etc., can solve the problems of heavy weight, labor, and poor effect of removing air bubbles, and achieve the effect of improved efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

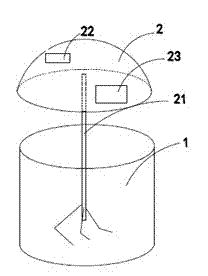

[0010] An ink mixer for lithographic offset printing, such as figure 1 As shown, consistent with the prior art, the mixer includes a mixing tank 1 on which a cylinder cover 2 is sealed. The cylinder head 2 is provided with a stirring rod 21, and the stirring rod 21 passes through the cylinder head 2 and is connected to a motor above the cylinder head 2 (not shown in the figure). The cylinder head 2 also includes a vacuum device, the vacuum device includes a vacuum pump, and the vacuum tube 22 of the vacuum pump is fixed on the cylinder head 2 . Such a structure can be vacuumed while stirring, avoiding the prior art of first stirring and then vacuuming. The efficiency is higher, and in order to better observe the vacuuming situation, a transparent visible window 23 for observation is provided on the cylinder head 2 .

[0011] The present invention still has many specific implementation modes, and all technical solutions formed by adopting equivalent replacement or equivalent ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap