Device and method for cold press molding of diamond positioning arranging cutter

A cold-press forming and diamond technology is applied in the field of cold-pressing forming devices of diamond positioning and arranging cutting tools, which can solve the problems of unrealistic needle bar control, high maintenance and manufacturing costs, and achieve low mold and process costs, simple preparation, and low cost. The effect of good application and promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

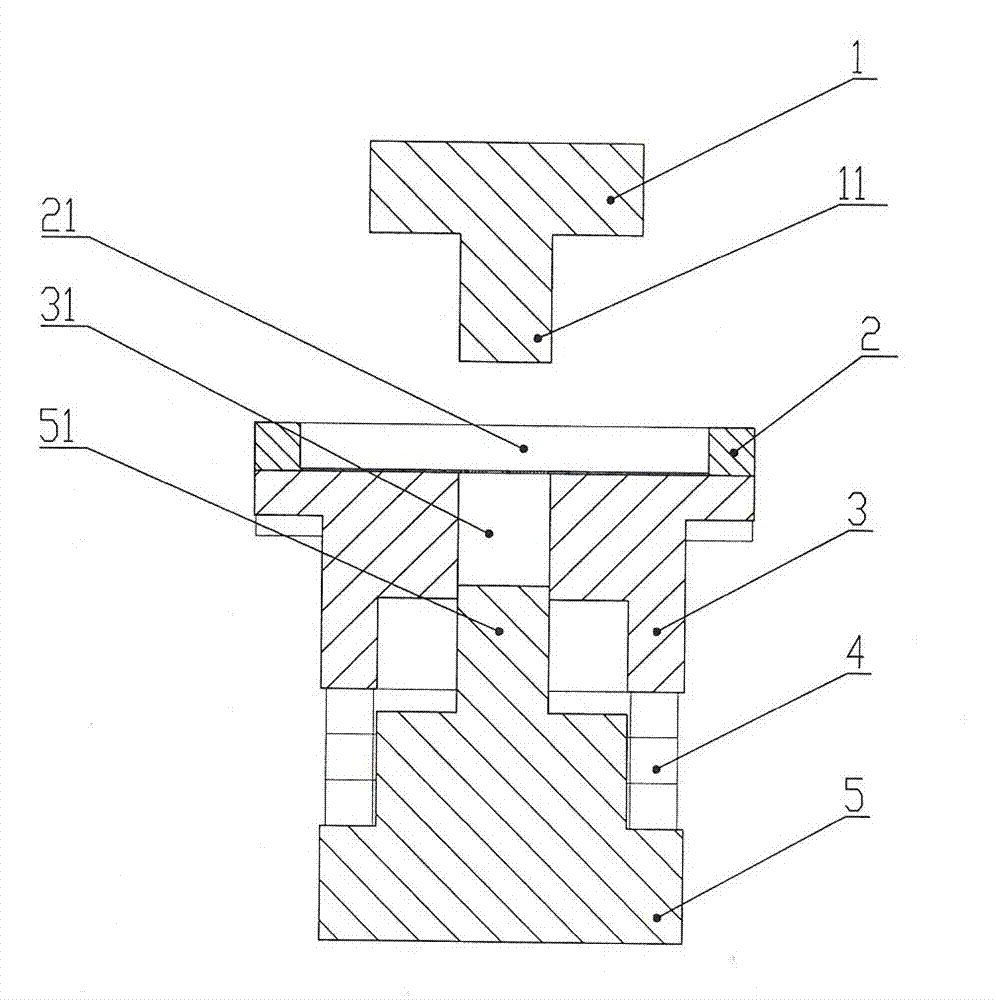

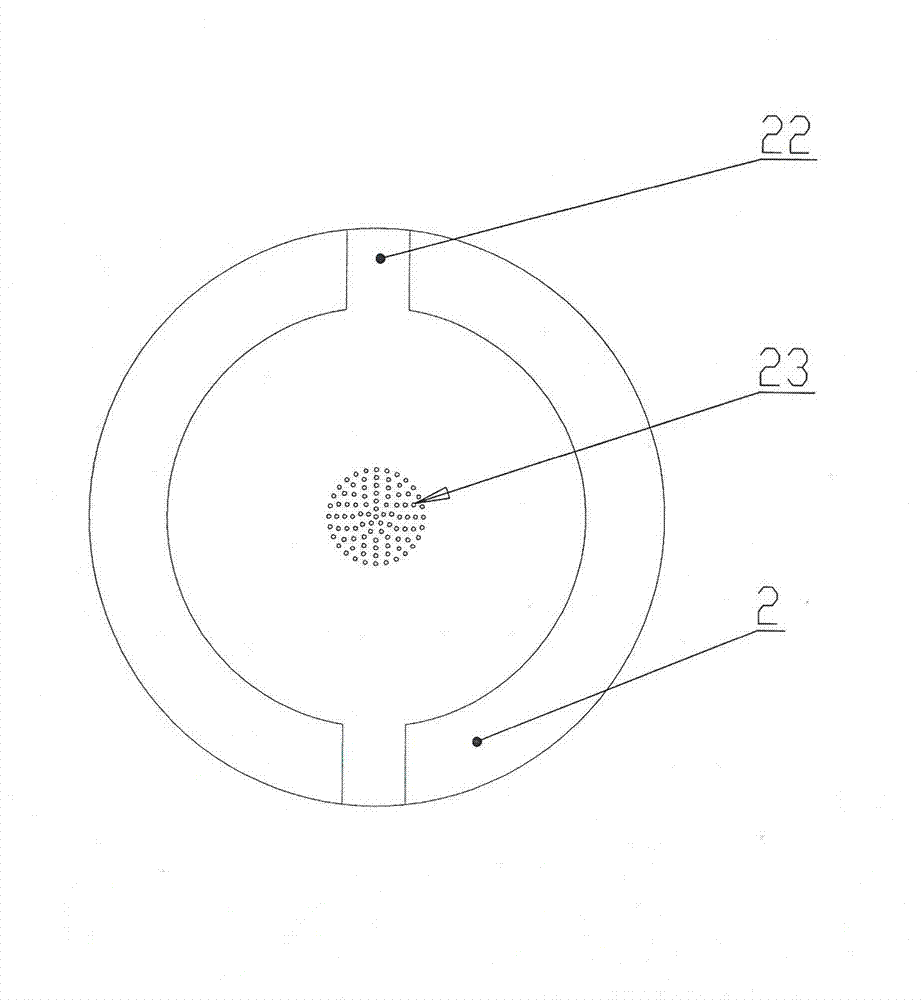

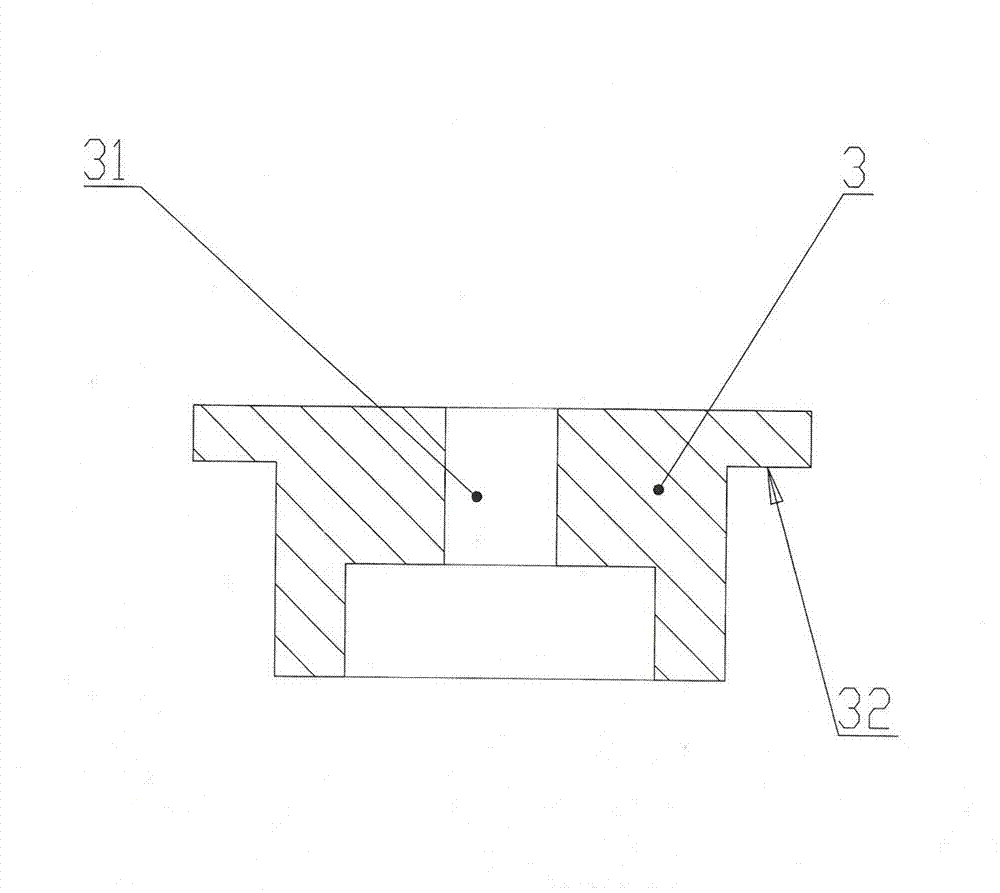

[0016] see figure 1 figure 2 , image 3 with Figure 4 As shown, the diamond positioning arrangement cutting tool cold press forming device of the present invention is made up of die 1, grid 2, cover die 3, spacer 4 and bottom die 5, cover die 3 is arranged on the bottom die 5, pad The sheet 4 is located between the bottom mold 5 and the cover mold 3, the pressure head 51 on the bottom mold 5 cooperates with the inner hole 31 of the cover mold 3, the grid 2 is arranged on the cover mold 3, and the center of the grid 2 has a plurality of cylindrical holes 23. The stamper 1 is located above the cover mold 3, and the bottom of the stamper 1 has an indenter 11, and the indenter 51 and the indenter 11 are located in the inner hole 31. The stamper 1, the cover mold 3, and the bottom mold 5 is made of hard alloy, and the material of grid 2 is cast aluminum 6005A.

[0017] The method for cold forming of the diamond positioning arrangement cutting tool of the present invention com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com